Driven wheel structure

A passive wheel and passive technology, applied in the field of manipulators, can solve the problems of inconvenient adjustment, troublesome assembly and disassembly of passive wheels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

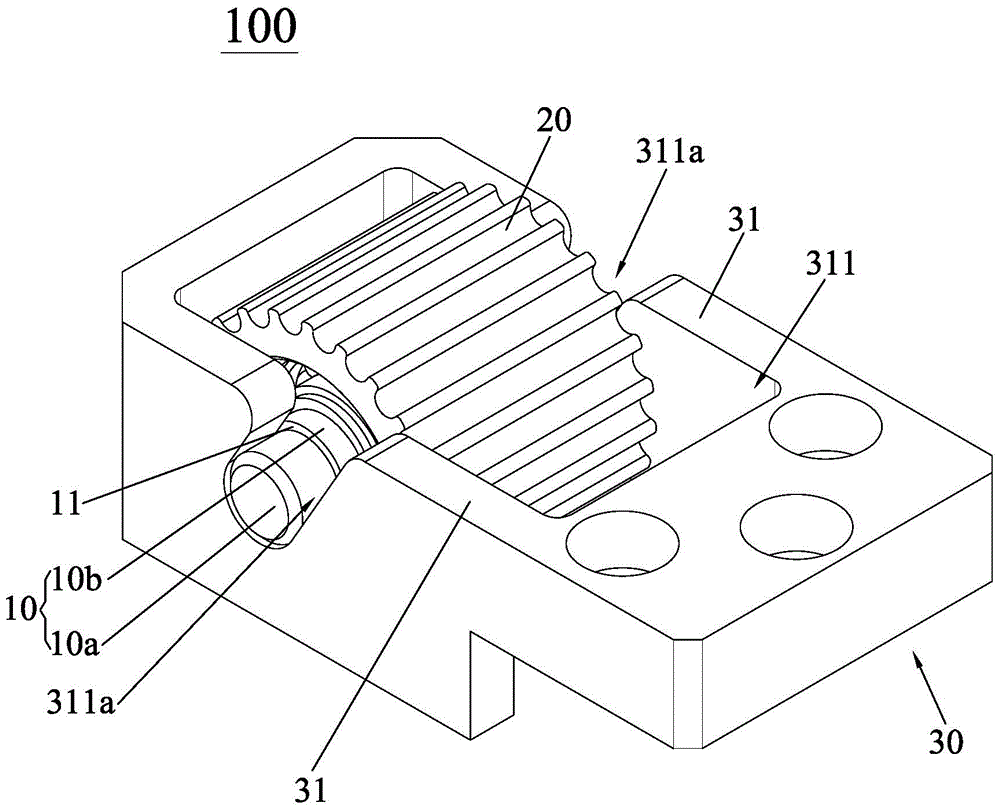

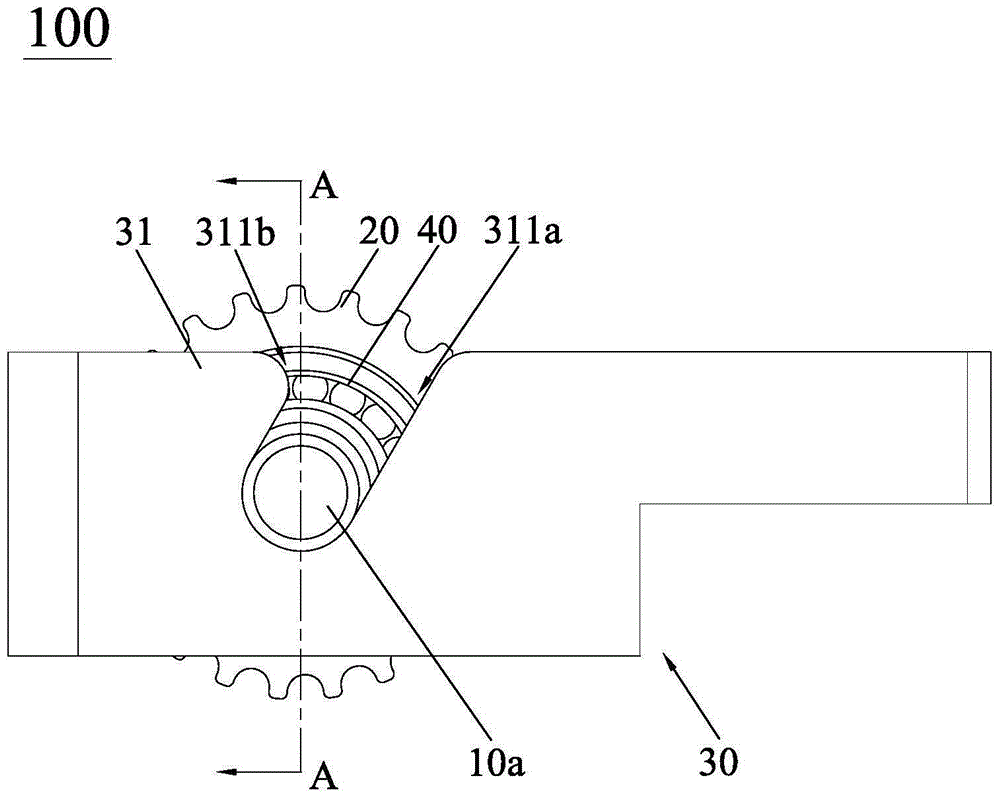

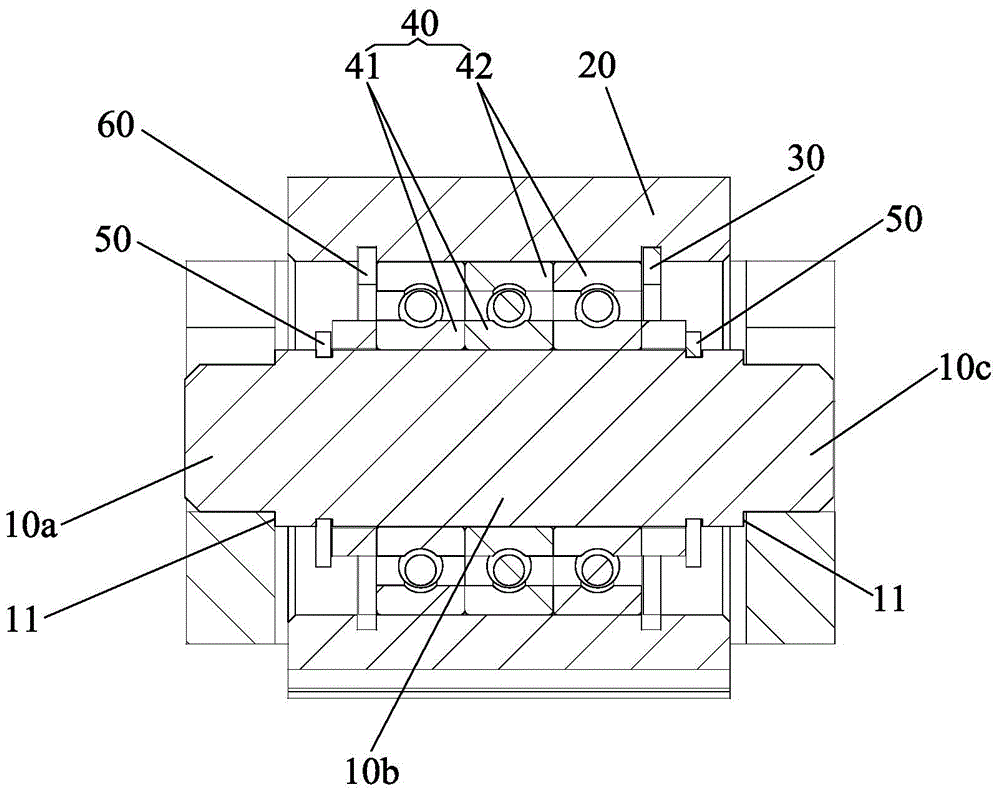

[0023] see Figure 1 to Figure 3 , The driven wheel structure 100 of the present invention includes a fixed shaft 10 , a driven wheel 20 and a support seat 30 of a hollow structure. The hollow structure penetrates the support base 30 along the first direction and forms an accommodating cavity 31 for the passive wheel 20 to be accommodated; specifically, in this embodiment, the hollow structure penetrates the support base 30 from bottom to top. , so the first direction in this embodiment refers to the direction from bottom to top of the support seat 30, of course, in other embodiments, the first direction can also refer to the direction from top to bottom of the support seat 30, or the direction of the support seat 30 from the front The direction to the back or from

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap