Preparation method of environment-friendly electric car cable aluminum alloy rod

A technology of electric vehicles and aluminum alloy rods, which is applied in the field of alloys, can solve the problems of limited distance, poor conductivity, and accidents, and achieve good integrity, high elongation and fatigue resistance, and prevent the alloy from being oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

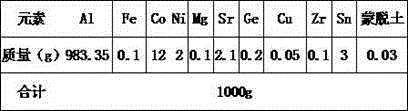

[0041] Table 1 Composition and content of aluminum alloy conductor materials

[0042]

[0043] (1) Put 983.35g of aluminum ingots into the furnace according to the quality of the metal elements listed in the above table, heat and melt under the condition of nitrogen filling, and keep it at 700°C;

[0044] (2) According to the amount shown in the above table, add Fe, Co, Ni, Mg, Sr, Ge, Cu, Zr, Sn and other metals into the molten aluminum, stir for 0.5h to make it uniform, then stand still and place at 700 Keep warm at ℃ for 0.5h;

[0045] (3) Add 3g of refining agent to the alloy melt, stir evenly, and then let it stand for 30 minutes. The melt refining is operated in a sealed environment; , and after degassing and slag removal, enter the casting machine for casting to obtain aluminum alloy ingots;

[0046] (4) Heat the aluminum alloy ingot to 670°C for 5 hours for the first solid solution treatment, and the cooling medium used is water;

[0047] (5) Heat the aluminum alloy

Embodiment 2

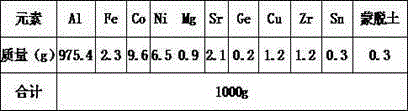

[0051] Table 2 Composition and content of aluminum alloy conductor materials

[0052]

[0053] (1) Put 975.4g of aluminum ingots into the furnace according to the quality of the metal elements listed in the above table, heat and melt under the condition of nitrogen filling, and keep it at 700°C;

[0054](2) According to the amount shown in the above table, add Fe, Co, Ni, Mg, Sr, montmorillonite, Ge, Cu, Zr, Sn and other metals into the molten aluminum, stir for 0.5h to make it uniform, and then Stand still and keep warm at 700°C for 1h;

[0055] (3) Add 3g of refining agent to the alloy melt, stir evenly, and then let it stand for 30 minutes. The melt refining is operated in a sealed environment; , and after degassing and slag removal, enter the casting machine for casting to obtain aluminum alloy ingots;

[0056] (4) Heat the aluminum alloy ingot to 670°C for a holding time of 10 hours for the first solid solution treatment, and the cooling medium used is clear water;

[

Embodiment 3

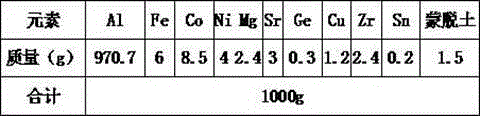

[0061] Table 3 Composition and content of aluminum alloy conductor materials

[0062]

[0063] (1) Put 973.8g of aluminum ingots and 3g of Sn into the furnace according to the quality of the metal elements listed in the above table, heat and melt under the condition of nitrogen filling, and keep the temperature at 700°C;

[0064] (2) According to the amount shown in the above table, add Fe, Co, Ni, Mg, Sr, montmorillonite, Ge, Cu, Zr and other metals into the molten aluminum, stir for 0.5h to make it uniform, then stand still and Incubate at 700°C for 1 hour;

[0065] (3) Add 3g of refining agent to the alloy melt, stir evenly, and then let it stand for 30 minutes. The melt refining is operated in a sealed environment; , and after degassing and slag removal, enter the casting machine for casting to obtain aluminum alloy ingots;

[0066] (4) Heat the aluminum alloy ingot to 770°C for a holding time of 10 hours for the first solid solution treatment, and the cooling medium use

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap