Automatic concrete test block sorting and storing method and system

A concrete test block and storage method technology, applied in the direction of sorting, etc., can solve the problems of untimely detection of expired samples, limitation of transfer and storage time, low transfer and storage efficiency, etc., to eliminate early detection of samples and avoid artificial Effects of operator error, improved transshipment and storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

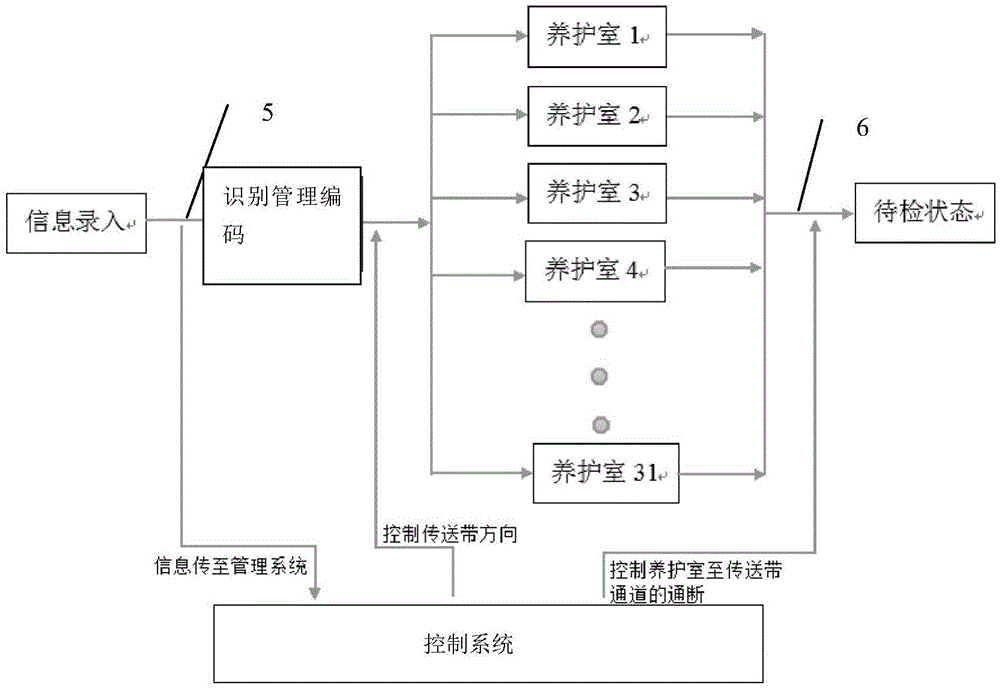

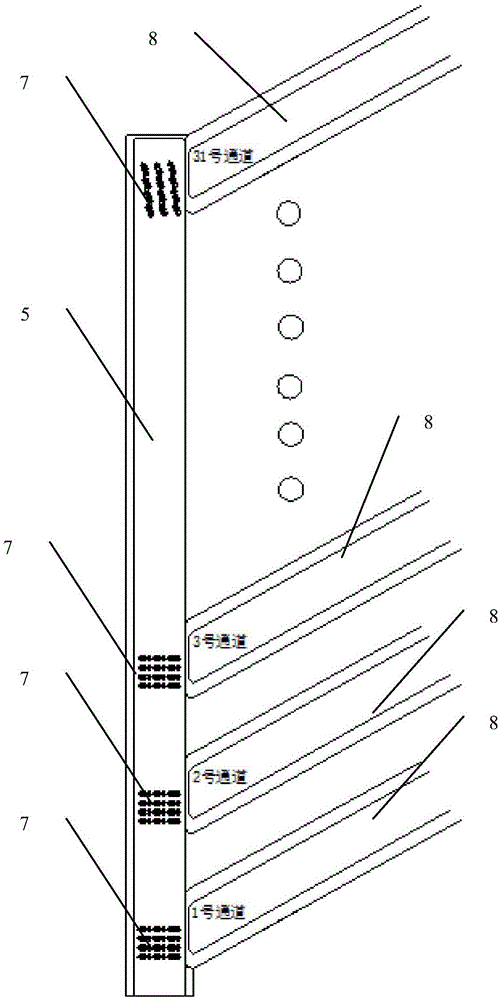

[0038] like figure 1 , 2 Shown, be a kind of concrete test block automatic sorting and storage method of the present invention, comprise the following steps:

[0039] 1. Put the 150*150*150 pieces on the warehousing conveyor belt, input the information of the concrete test block into the computer, and the main information of the concrete test block (forming date, age and compressive strength) is fed back to the control system. A digital code, self-edited as 1, 2, 3-28, which means the number of days from the concrete test block to the forming date (age), the longest age is 28 days, and the shortest is 1 day. For example, the molding date is July 19, and the sample delivery date is July 14. The digital code generated at this time is 5, which means that there are still 5 days before the molding date.

[0040]2. The digital code is transmitted to the control system. At this time, according to the digital code, the control system converts the decimal code into binary code. For exa

Embodiment 2

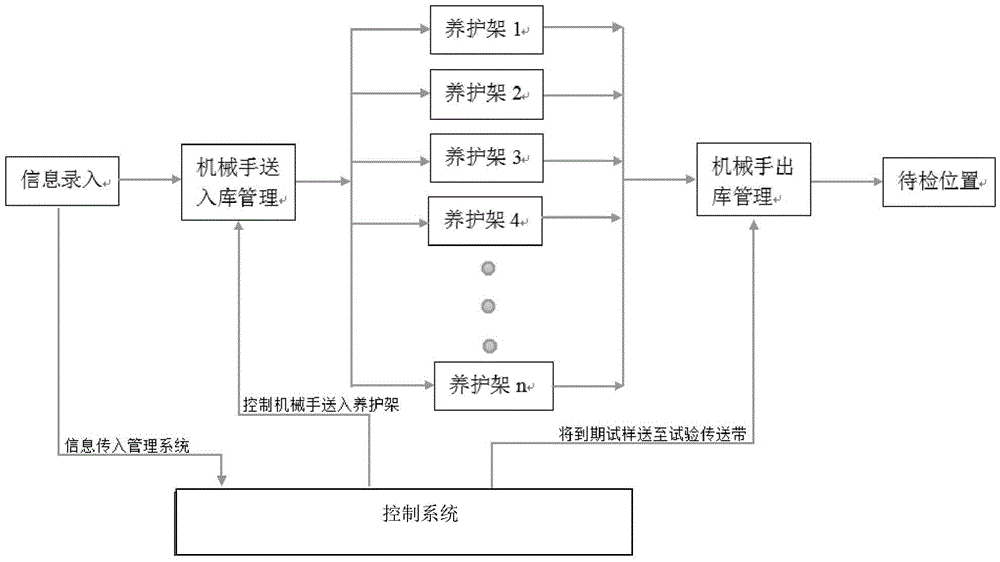

[0057] like image 3 As shown, the difference between this embodiment and the embodiment is that each curing room is respectively connected to the first conveying mechanism 5 and the second conveying mechanism 6 through manipulators, and the curing chamber is provided with a curing frame for placing concrete test blocks. The manipulator is controlled by the control system (same as image 3 The management system in the system) controls the concrete test block delivered by the first conveying mechanism 5 to the curing rack in the curing room for curing, and at the same time transmits the specific position information of the concrete test block to the control system, and the concrete test block reaches After the age, the control system controls the manipulator to grab the concrete test block at the corresponding position and send it to the position to be inspected on the second conveying mechanism 6 .

[0058] Compared with Example 1, which uses a diverting conveyor belt to transpo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap