Rubber asphalt mixture with high-temperature storage stability and preparation method thereof

A rubber asphalt and high-temperature storage technology, which is applied to building structures, building insulation materials, building components, etc., can solve problems such as insufficient storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

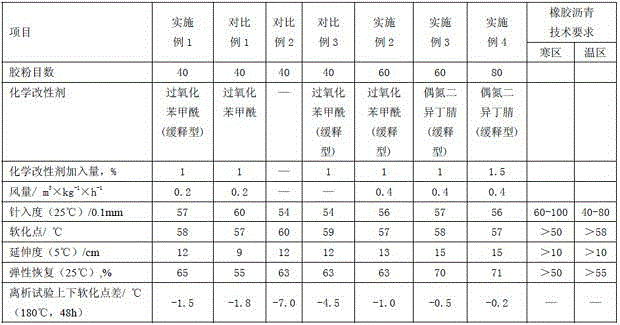

Embodiment 1

[0033] Rubber asphalt composition proportioning of the present invention is as follows:

[0034] 40 mesh rubber powder 15%

[0035] Base bitumen 84%

[0036] Slow-release chemical modifier (benzoyl peroxide) 1%

[0037] The preparation process is as follows

[0038] (1) Heat Zhenhai base asphalt with a penetration (25°C) of No. 110 to 180°C-190°C, add 40-mesh waste tire rubber powder, stir for 10 minutes, and then perform high-shear grinding for 2 to 3 times before placing Stir in the development tank for 1h;

[0039] (2) Add 1% slow-release chemical modifier (benzoyl peroxide), stir evenly, and then inject compressed air from the bottom of the tank. Air volume is 0.2m 3 × kg -1 × h -1 . Continue to stir for 1 hour, and the properties of rubber asphalt are shown in Table 1.

Embodiment 2

[0058] 60 mesh rubber powder 15%

[0059] Base bitumen 84%

[0060] Slow-release chemical modifier (benzoyl peroxide) 1%

[0061] The preparation process is as follows

[0062] (1) Heat Zhenhai base asphalt with a penetration (25°C) of No. 110 to 180°C-190°C, add 60 mesh waste tire rubber powder and stir for 15 minutes, then undergo high-shear grinding for 2 to 3 times before developing Stir in the tank for 1.5h,

[0063] (2) Add 1% slow-release chemical modifier (benzoyl peroxide), stir evenly, and then inject compressed air from the bottom of the tank. Air volume is 0.4m 3 × kg -1 × h -1 . Continue to stir for 1 hour, and the properties of rubber asphalt are shown in Table 1.

Embodiment 3

[0065] 60 mesh rubber powder 15%

[0066] Base bitumen 84%

[0067] Slow-release chemical modifier (azobisisobutyronitrile) 1%

[0068] The preparation process is as follows

[0069] (1) Heat the Zhenhai base asphalt with a penetration (25°C) of No. 110 to 180°C-190°C, add 40 mesh waste tire rubber powder and stir for 10 minutes, and then undergo high-shear grinding for 2 to 3 times before developing Stir in the tank for 1.5h,

[0070] (2) Add 1% slow-release chemical modifier (azobisisobutyronitrile), stir evenly, and then pass compressed air from the bottom of the tank. The air volume is 0.4m 3 × kg -1 × h -1 . Continue to stir for 1 hour, and the properties of rubber asphalt are shown in Table 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap