Crane capable of being integrally lowered

A technology of overall height and crane, applied in the direction of trolley cranes, cranes, load trolleys, etc., can solve the problems of inconvenient use of enterprises and large loss of lifting height of double-girder cranes, and achieve a light frame, reduce the weight of the trolley, reduce the The effect of cart height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing:

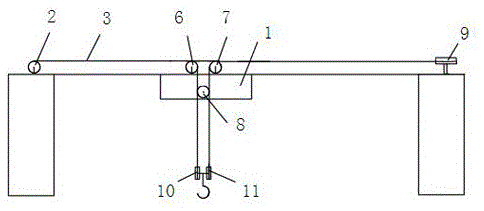

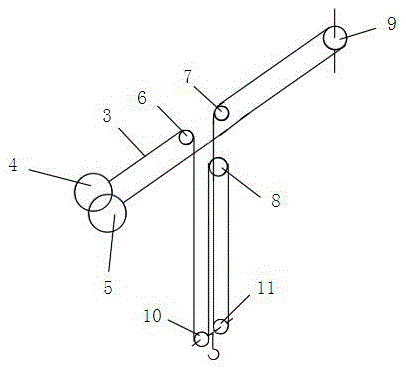

[0013] A crane capable of reducing the overall height, comprising a trolley (1), a reel (2), the reel (2) is arranged on the left beam end, the reel (2) is connected to a motor, and a steel wire (3 ), characterized in that the steel wire (3) is wound with a first planar helical coil (4) and a second planar helical coil (5) on the reel (2), and the first planar helical coil (4 ) is in the same winding direction as the second planar helical coil (5), and the trolley (1) is fixed with a first wheel (6) and a second wheel (7) on one side of the main beam, and the trolley (1) ) A fixed pulley (8) is fixed on one side of the other main beam, and a horizontal fixed pulley (9) is fixed on the right beam end, and the steel wire (3) is wound into the first plane spiral coil (4) and then wound Pass the first wheel (6), then bypass the first movable pulley (10), then bypass the fixed pul

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap