Wafer ice cream cone and preparation method thereof

An ice cream, weight technology, applied in the direction of frozen dessert, food science, application, etc., to achieve the effect of good taste, good sweet potato taste, and realistic sweet potato shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

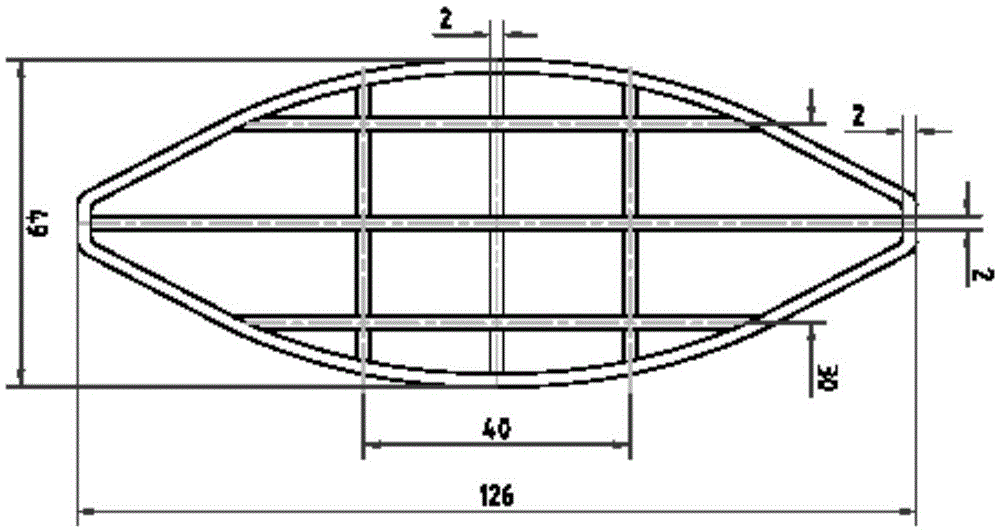

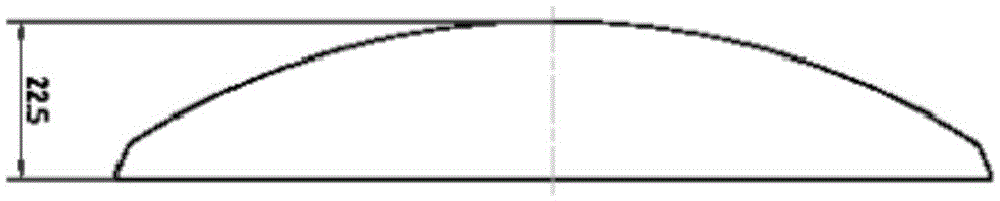

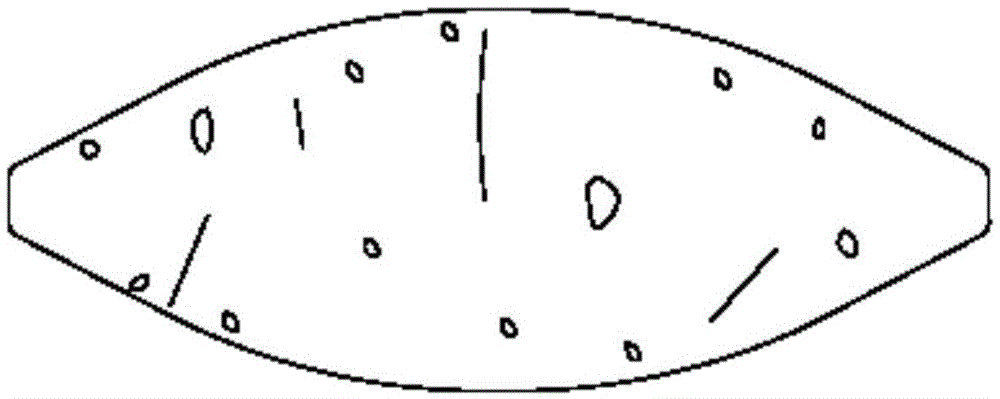

Image

Examples

Embodiment 1

[0026] Embodiment 1 prepares sweet potato modeling wafer ice cream cone (adding pulp and coloring)

[0027] The raw materials are as follows:

[0028] Flour: 27% Cornstarch: 15% Sweet potato pulp 5% Salt: 0.2%

[0029] Salad oil: 1.5% Drinking water: 50%

[0030] Fluffy agent: sodium bicarbonate: 0.3%;

[0031] Food flavor and pigment: 0.1%;

[0032] The preparation process is as follows:

[0033] Adding water—mixing raw materials—feeding—locking—baking—out of the mold—finished product

[0034] 1. Raw material inspection: must pass sensory, physical and chemical inspection, microbiological test, no adulteration and other foreign matter; meet the relevant national or industry standards for raw materials.

[0035] 2. Preparation of raw materials: Involving raw materials such as flour, cornstarch, salad oil, sodium bicarbonate, etc. are weighed accurately for use.

[0036] 3. Raw material mixing: first add water (temperature < 25°C) to the batching tank, then add the prepared

Embodiment 2

[0041] Example 2 Preparation of Sweet Potato Shaped Wafer Ice Cream Cone (Adding Slurry and Coloring)

[0042] The raw materials are as follows:

[0043] Flour: 27% Cornstarch: 15% Sweet potato pulp 7% Salt: 0.2%

[0044] Salad oil: 1.5% Drinking water: 50%

[0045] Fluffy agent: sodium bicarbonate: 0.3%;

[0046] Food flavor and pigment: 0.1%;

[0047] The preparation process is as follows:

[0048] Adding water—mixing raw materials—feeding—locking—baking—out of the mold—finished product

[0049] 1. Raw material inspection: must pass sensory, physical and chemical inspection, microbiological test, no adulteration and other foreign matter; meet the relevant national or industry standards for raw materials.

[0050] 2. Preparation of raw materials: Involving raw materials such as flour, cornstarch, salad oil, sodium bicarbonate, etc. are weighed accurately for use.

[0051] 3. Raw material mixing: first add water (temperature < 25°C) to the batching tank, then add the prepar

Embodiment 3

[0056] Example 3 Preparation of Sweet Potato Shaped Wafer Ice Cream Cone (Adding Slurry and Coloring)

[0057] The raw materials are as follows:

[0058] Flour: 27% Cornstarch: 15% Sweet potato pulp 3% Salt: 0.2%

[0059] Salad oil: 1.5% Drinking water: 50%

[0060] Fluffy agent: sodium bicarbonate: 0.3%;

[0061] Food flavor and pigment: 0.1%;

[0062] The preparation process is as follows:

[0063] Adding water—mixing raw materials—feeding—locking—baking—out of the mold—finished product

[0064] 1. Raw material inspection: must pass sensory, physical and chemical inspection, microbiological test, no adulteration and other foreign matter; meet the relevant national or industry standards for raw materials.

[0065]2. Preparation of raw materials: Involving raw materials such as flour, cornstarch, salad oil, sodium bicarbonate, etc. are weighed accurately for use.

[0066] 3. Raw material mixing: first add water (temperature < 25°C) to the batching tank, then add the prepare

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap