Punching head structure for sheet metal punching

A punching head and punching technology, which is applied in the field of sheet metal processing, can solve the problems of low hole processing quality, affecting the quality of the plate, and many burrs on the edge of the hole, so as to reduce deformation, improve punching quality, and improve punching quality. speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

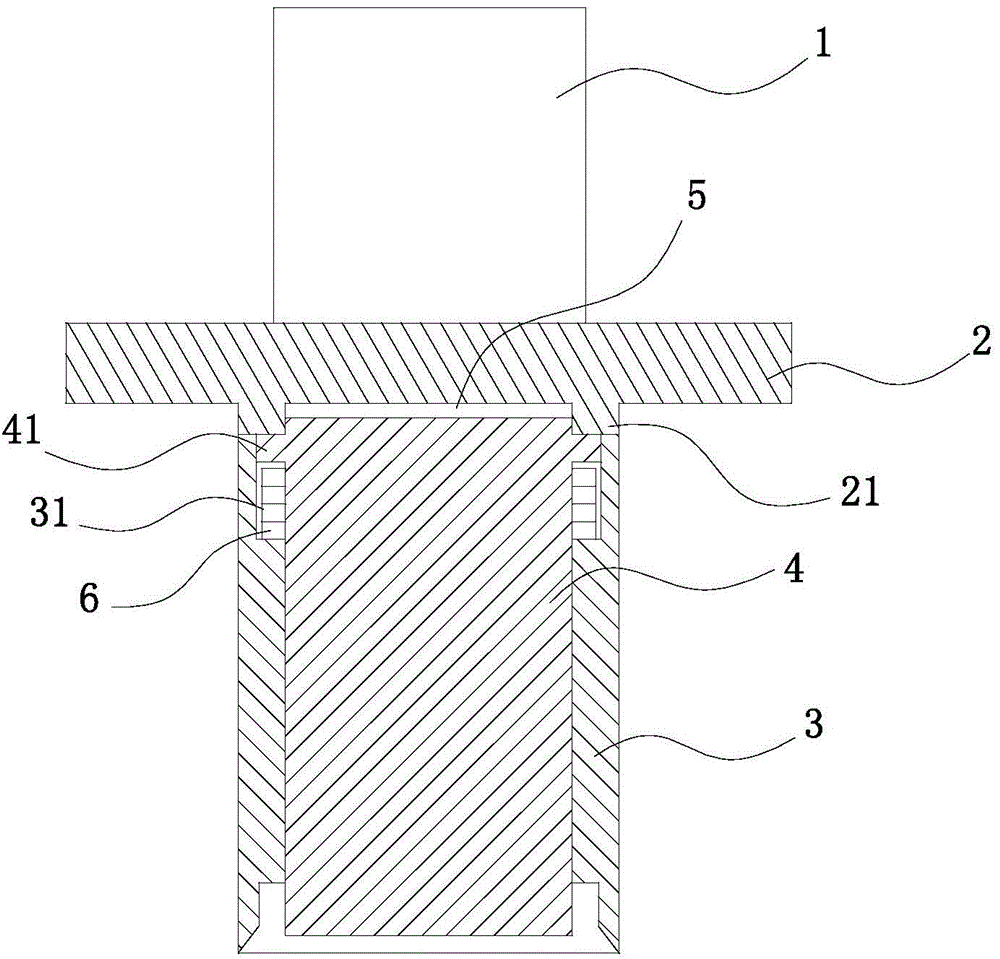

[0012] See figure 1 , the present invention comprises a punching driving device 1, an upper template 2 and a punching head 3, the punching driving device 1 drives the upper template 2 to drive the punching head 3 to reciprocate up and down; the punching head 3 is equipped with a punch 4, punching The inner side wall of the upper end of the head 3 is symmetrically provided with a chute 31, and the chute 31 is slidably connected with the slider 41 on the outer wall of the upper end of the punch 4. The multilayer buffer pad 6 is respectively installed in the chute 31, and the upper and lower sides of the multilayer buffer pad 6 The two ends are respectively close to the bottom surface of the slider 41 and the chute 31; the punch 4 is staggered in the punching head 3, that is, the lower end surface and the upper end surface of the punching head 4

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap