Flameproof anti-explosion water washing chamber structure in carrier vehicle

A technology for transport vehicles and water washing boxes, which is applied in the directions of dust prevention, fire prevention, mining equipment, etc., can solve the problems of unstable driving, poor adaptability, easy to cut tires, etc., to improve reliability, improve efficiency, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0010] Example 1

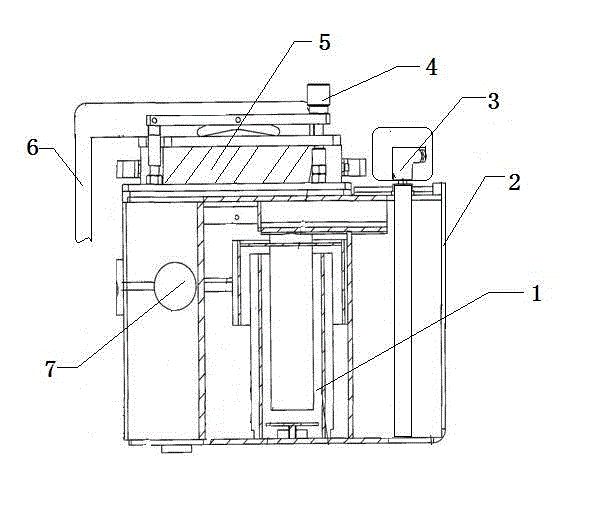

[0011] This embodiment provides a water washing tank structure in an explosion-proof and explosion-proof transport vehicle, which is characterized in that: the water washing tank structure in the explosion-proof and explosion-proof transport vehicle includes a mixing pipe (1), a water tank (2), Water level sensor (3), locking device (4), fire barrier (5), exhaust pipe (6), position measuring float (7);

[0012] Among them: the lower part of the water tank (2) is provided with a mixing pipe (1), the exhaust pipe (6) is set on the top of the water tank (2), and the position measuring float (7) is set on the water surface of the water tank (2). The fire fence (5) is set at the lower part of the exhaust pipe (6), and the locking device (4) sets the shell of the water tank (2), and one end of the water level sensor (3) is set in the water tank (2), and the other end is set in the water tank ( 2) External.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap