Sun visor cosmetic mirror mounting structure and method

A technology of installation structure and installation method, applied in anti-glare equipment, transportation and packaging, vehicle parts, etc., can solve the problems of high repair rate, high scrap rate, and high manufacturing cost, and reduce maintenance costs, reduce scrap rates, and reduce The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following describes the implementation of the present invention through specific specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification. The present invention can also be implemented or applied through other different specific embodiments, and various details in this specification can also be modified or changed based on different viewpoints and applications without departing from the spirit of the present invention.

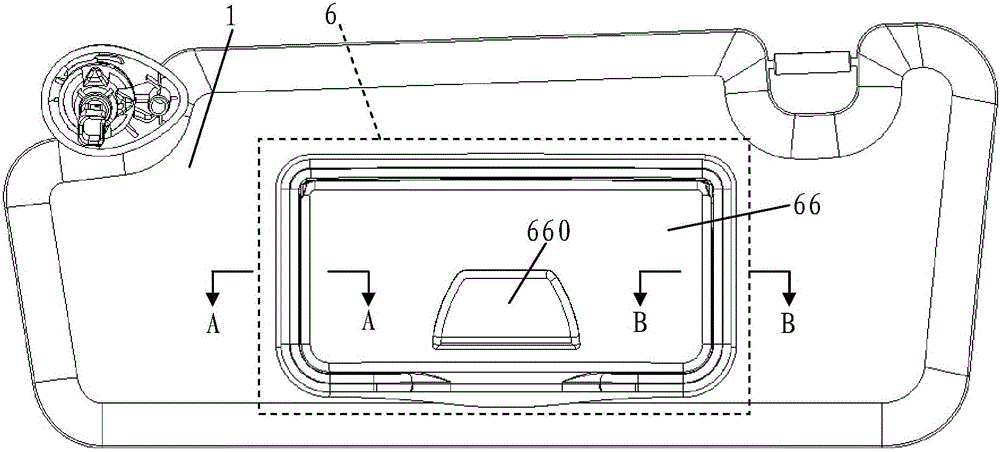

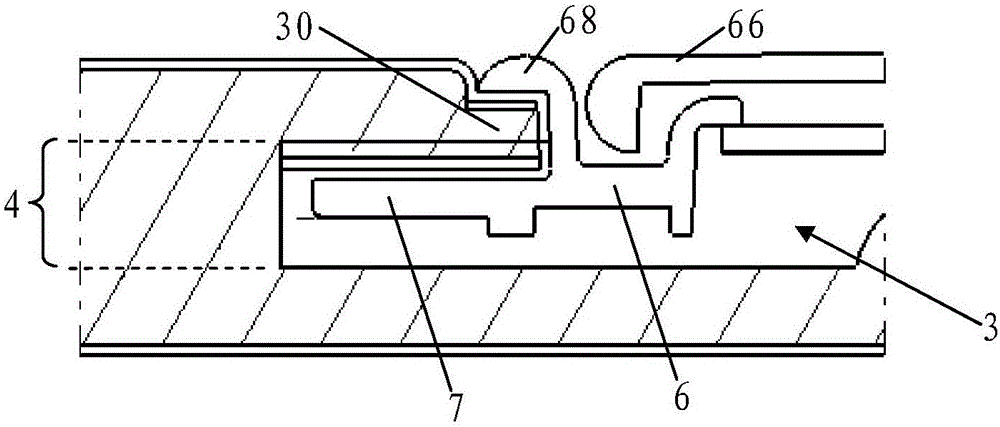

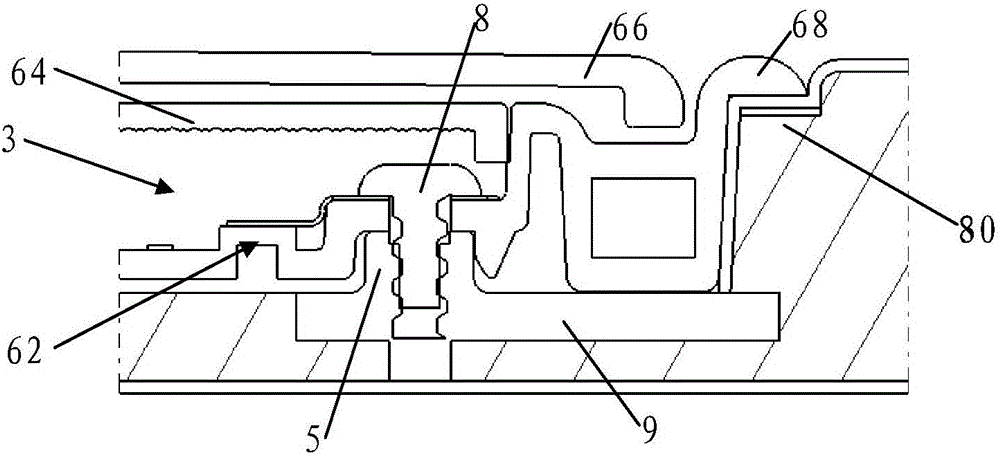

[0033] Combine Figure 1 to Figure 4 As shown, the present invention provides a sun visor vanity mirror installation structure. One side of the sun visor 1 has an installation groove 3, and one side of the installation groove 3 has a horizontally extending slot 4, and the installation groove The other side of the groove 3 has a screw hole 5, the vanity mirror 2 is fixedly mounted on a base 6, and one side of the base 6 is protrudingly provide

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap