Process for manufacturing square basin frames

A production process and pot frame technology, which is applied in the field of square pot frame production technology, can solve the problems of reduced surface roughness, high pot frame scrap rate, and high production cost, so as to reduce rework rate, production cost, and scrap rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

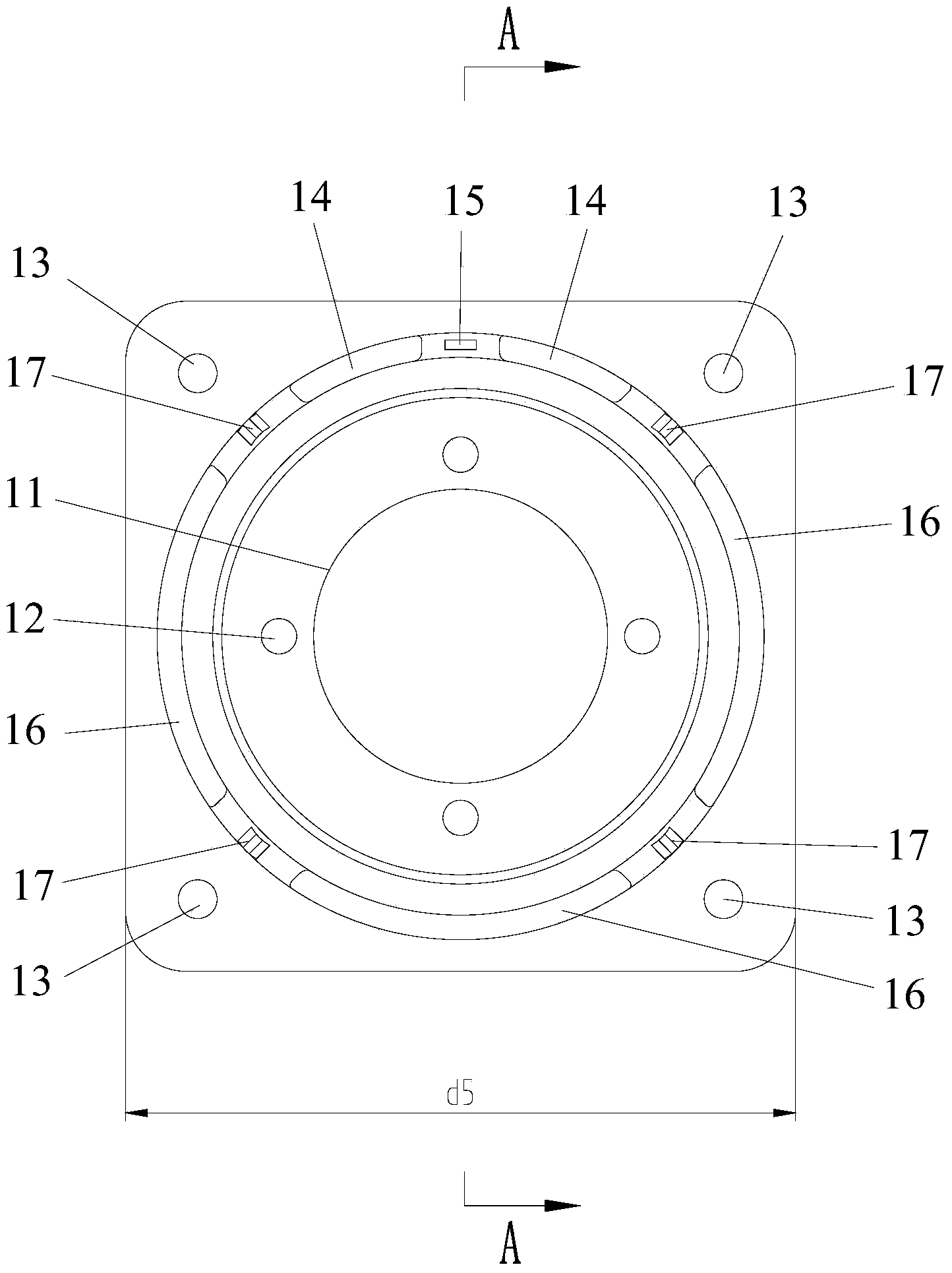

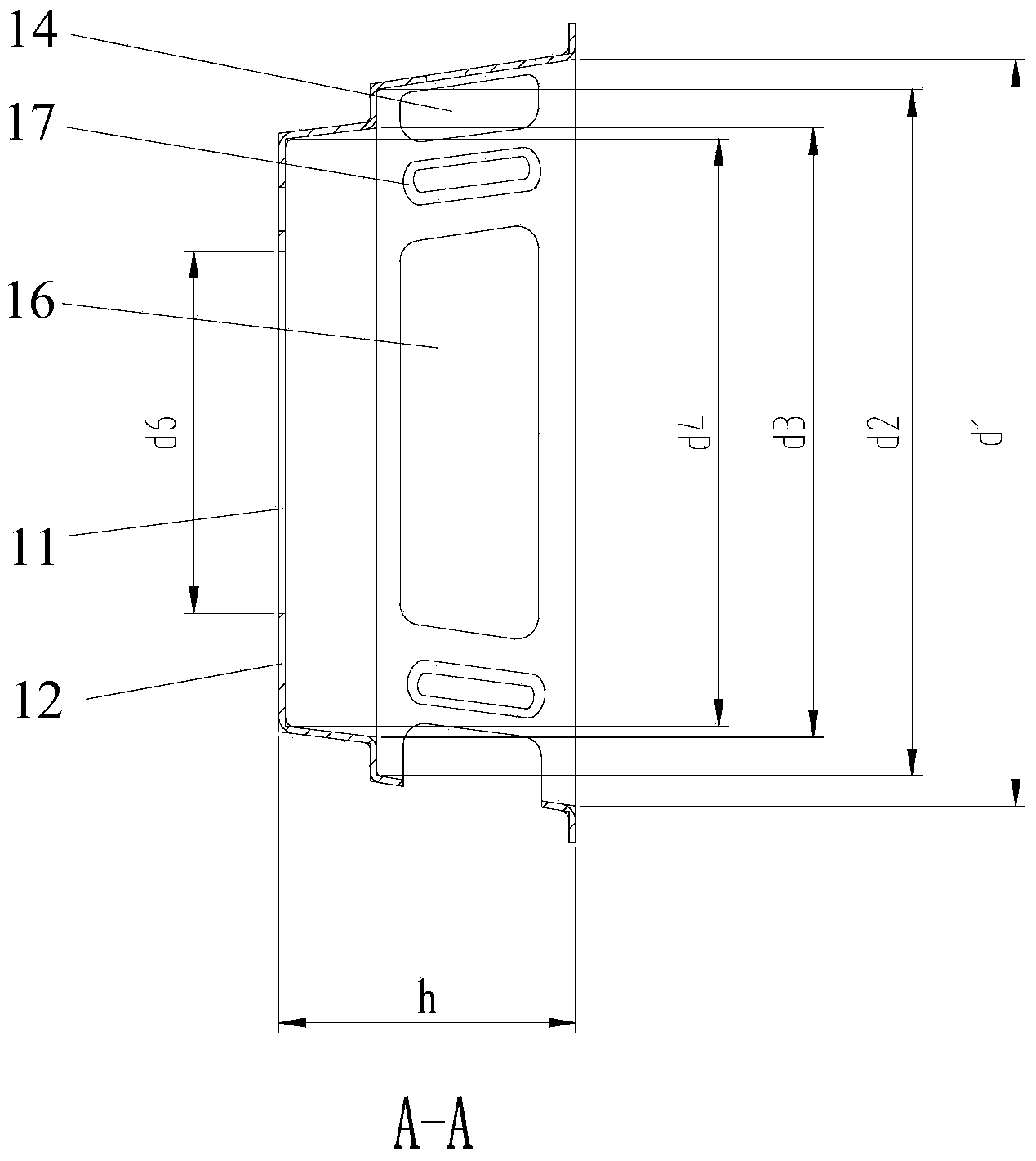

[0018] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

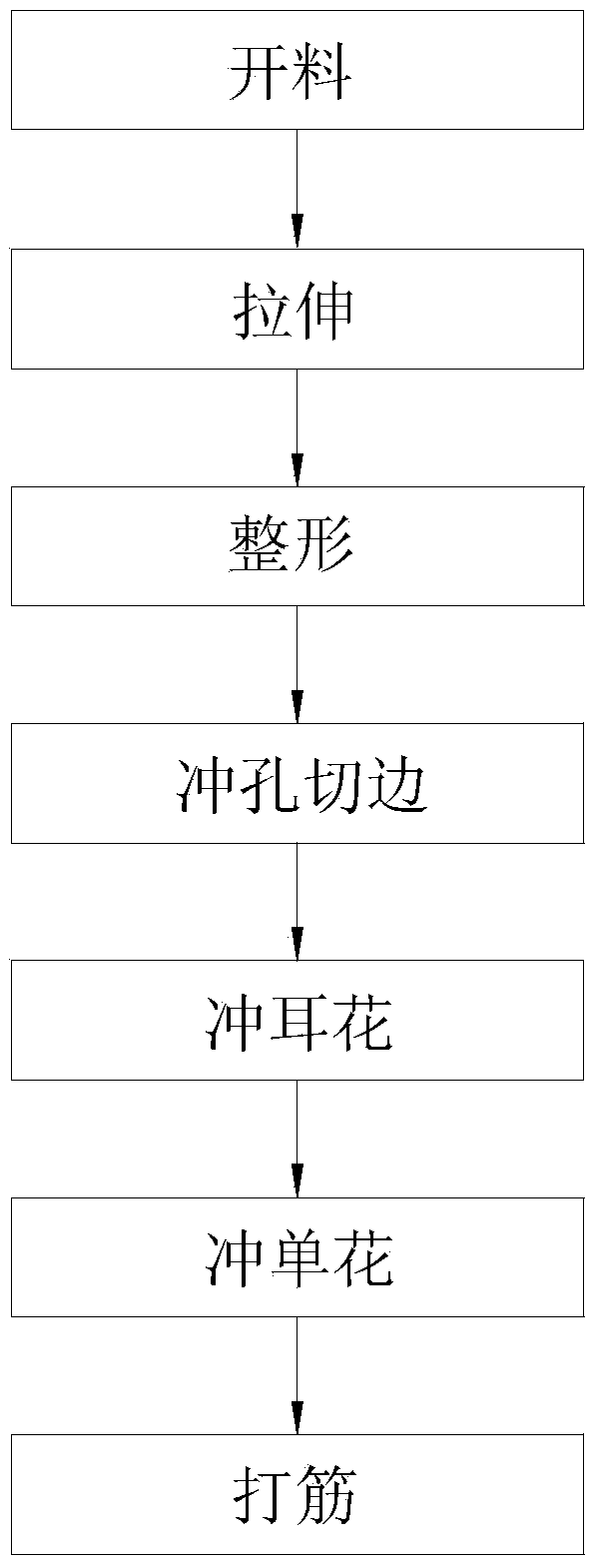

[0019] Please refer to Figure 1-3 , is a specific embodiment of the production process of the square basin frame of the present invention, and the process comprises steps as follows:

[0020] (1) Use a shearing machine to cut the 0.6mm thick material used to manufacture the basin frame to form a square material plate of 110mm×110mm.

[0021] (2) Use a single-cut material stretching die to stretch the square material plate formed after cutting at one time. The forming depth h is 27.9±0.3mm, and the diameters d1, d2, d3, and d4 are 70.2mm, 65mm, and 57.3mm, 55.2mm stepped basin blanks.

[0022] (3) Use the shaping mold to shape the stepped basin body blank.

[0023] (4) Utilize the trimming mold to carry out trimming on the edge of the stepped basin body blank, form the basin body 1 that has the square edge that length ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap