On-line grain charging and cooling device in alcohol brewage production and grain addition and mixing method

A wine and stirring device technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of affecting production, high labor intensity of workers, and low alcohol yield, so as to save floor space, reduce repeated investment, and increase alcohol yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

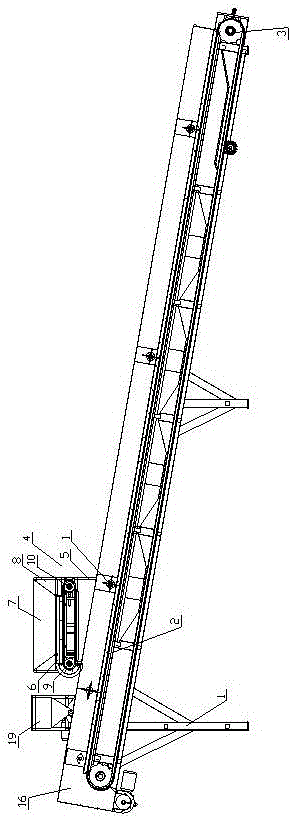

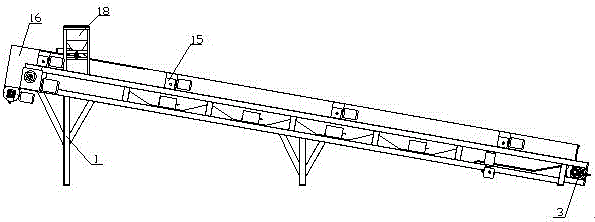

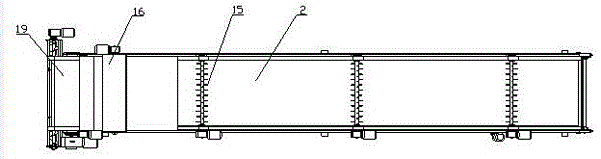

[0023] combine Figure 1-7 The shown online grain adding and cooling device in wine brewing production includes a frame 1 and a first conveying chain plate 2. The first conveying chain plate 2 is arranged on the frame 1 and is connected with a first driving mechanism 3. A conveyor feeder 4 is arranged above the conveyor chain plate 2. The conveyor feeder 4 includes a support frame 5 and a second conveyor chain plate 6. The support frame 5 is connected to the frame 1, and the second conveyor chain plate 6 is arranged on the support frame 5. , and arranged directly above the first conveyor chain plate 2, a hopper 7 is provided above the second conveyor chain plate 6, and a stirring device 15 is provided on the first conveyor chain plate 2 below the second conveyor ch

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap