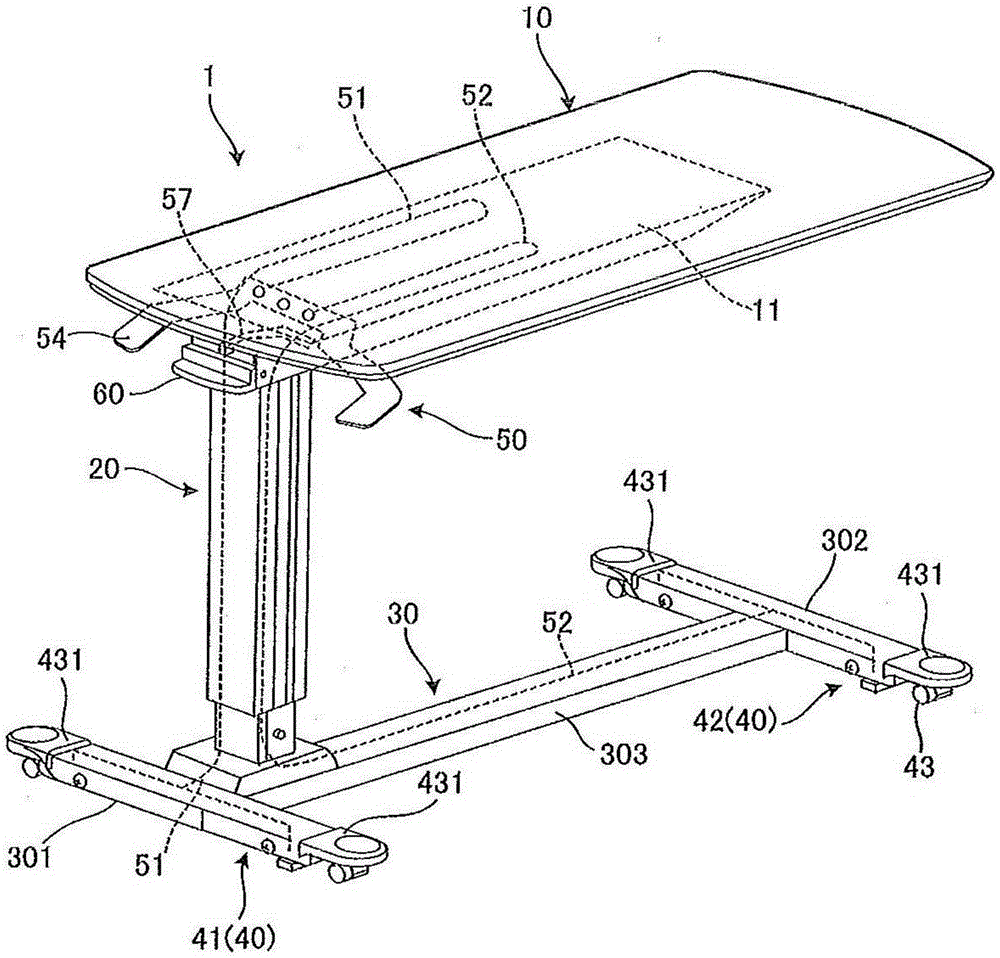

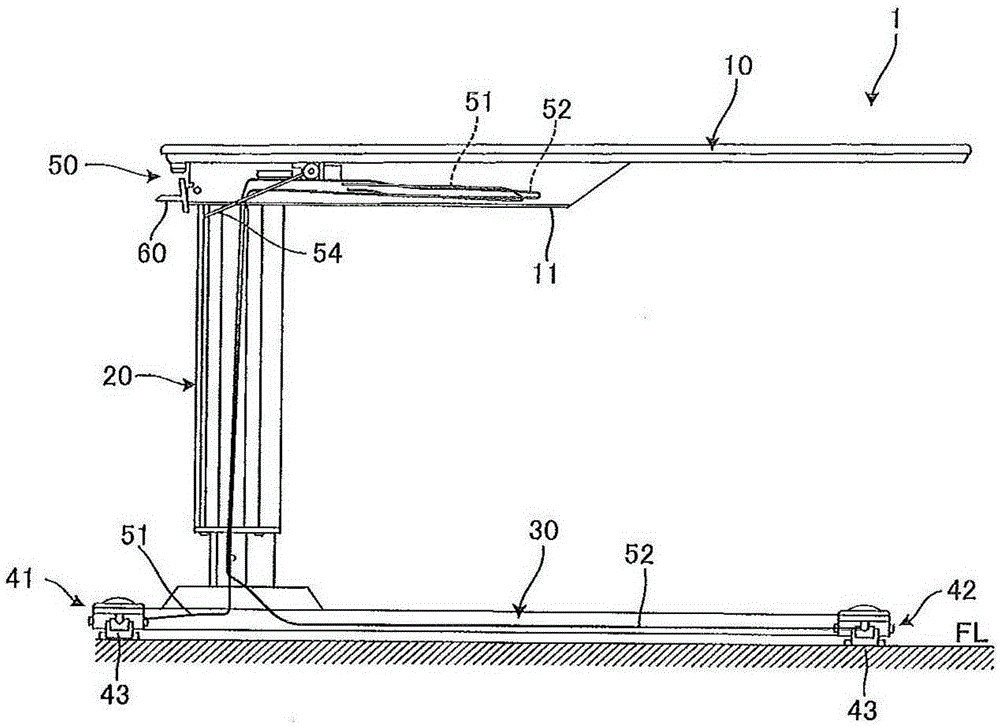

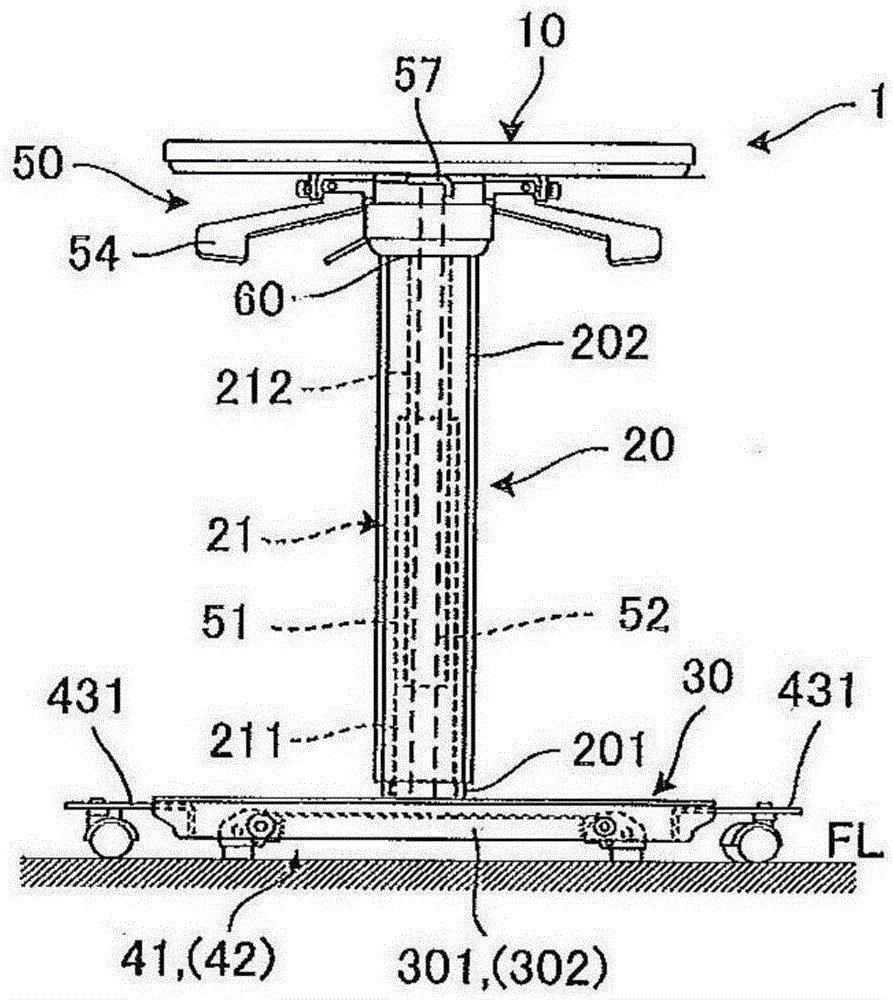

Brake mechanism and movable table provided with brake mechanism

A brake mechanism, mobile technology, applied in the direction of brake actuators, tables, mechanical equipment, etc., can solve the problems of increased user burden, small braking force, large braking force, etc., to achieve increased burden, The effect of simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0156] In Example 1, the structure of the brake part of the 1st brake mechanism 41 and the 2nd brake mechanism 42 in this embodiment is arrange|positioned in the opposite position.

[0157] Figure 18 It is an explanatory diagram showing an example in which the brake portion constituting the brake mechanism of the mobile table according to the present embodiment is tilted in the opposite direction.

[0158] like Figure 18 As shown, in Embodiment 1, the brake parts 420A and 420B of the first brake mechanism 41 in the first leg frame 301 of the leg part 30 are arranged at an angle of approximately 45 degrees relative to the width direction of the table and in a symmetrical direction of " In the position of "ハ", the brake parts 420C and 420D of the second brake mechanism 42 in the second leg frame 302 of the leg part 30 are arranged at an angle of approximately 45 degrees relative to the width direction of the table and in a symmetrical direction of " Inverted ハ character" posi

Embodiment 2

[0162] In Example 2, the structures of the braking parts of the first braking mechanism 41 and the second braking mechanism 42 in this embodiment are arranged in the same direction, and the longitudinal movement of the mobile table is effectively braked.

[0163] Figure 19 It is an explanatory diagram showing an example in which a braking unit constituting the braking mechanism of the movable table according to the present embodiment is arranged corresponding to the movement in the longitudinal direction of the movable table.

[0164] like Figure 19 As shown, in Embodiment 2, the brake parts 420A and 420B of the first brake mechanism 41 in the first leg frame 301 of the leg part 30 are paralleled in the same direction so as to brake the movement in the longitudinal direction of the table. It is provided that the brake parts 420C and 420D of the second brake mechanism 42 in the second leg frame 302 of the leg part 30 are arranged in parallel in a direction opposite to the direc

Embodiment 3

[0168] In Example 3, the structures of the braking parts of the first braking mechanism 41 and the second braking mechanism 42 in this embodiment are arranged in the same direction, and the movement in the width direction of the mobile table is effectively braked.

[0169] Figure 20 It is an explanatory diagram showing an example in which a brake portion constituting the brake mechanism of the movable table according to the present embodiment is arranged corresponding to the movement in the width direction of the movable table.

[0170] like Figure 20 As shown, in Embodiment 3, the brake parts 420A and 420B of the first brake mechanism 41 in the first leg frame 301 of the leg part 30 are arranged opposite to each other so as to brake the movement in the width direction of the table. The brake parts 420C and 420D of the second brake mechanism 42 in the second leg frame 302 of 30 are arranged facing each other in the same direction as the direction of 420A and 420B.

[0171] Th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap