Handle lock body and handle lock

A handle and main bolt technology, applied in the field of handle locks, can solve problems such as cumbersome door opening actions, common film jamming, noise, etc., and achieve the effect of convenient operation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

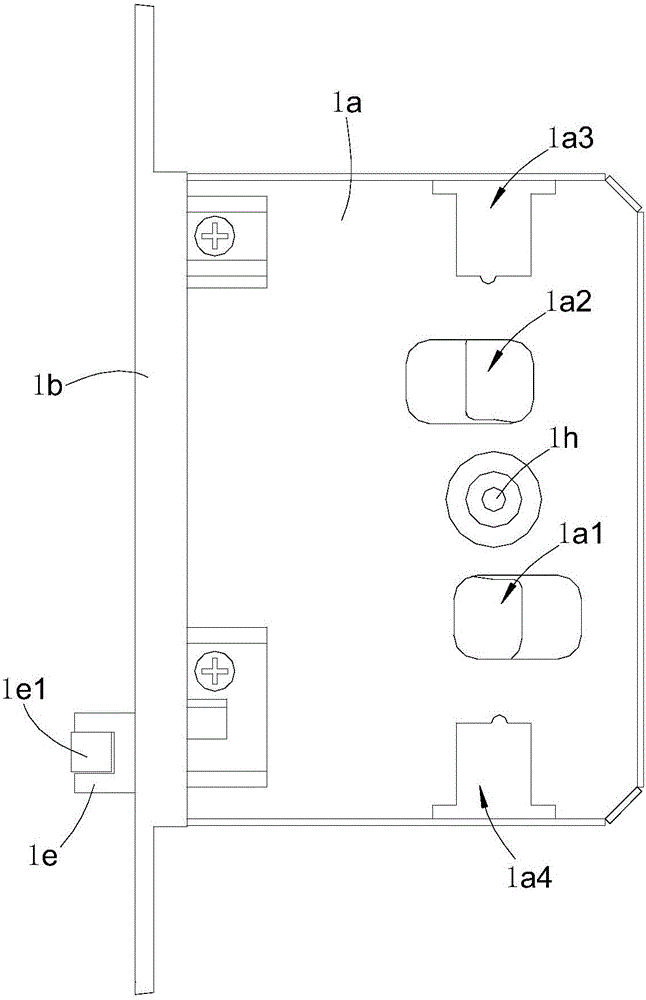

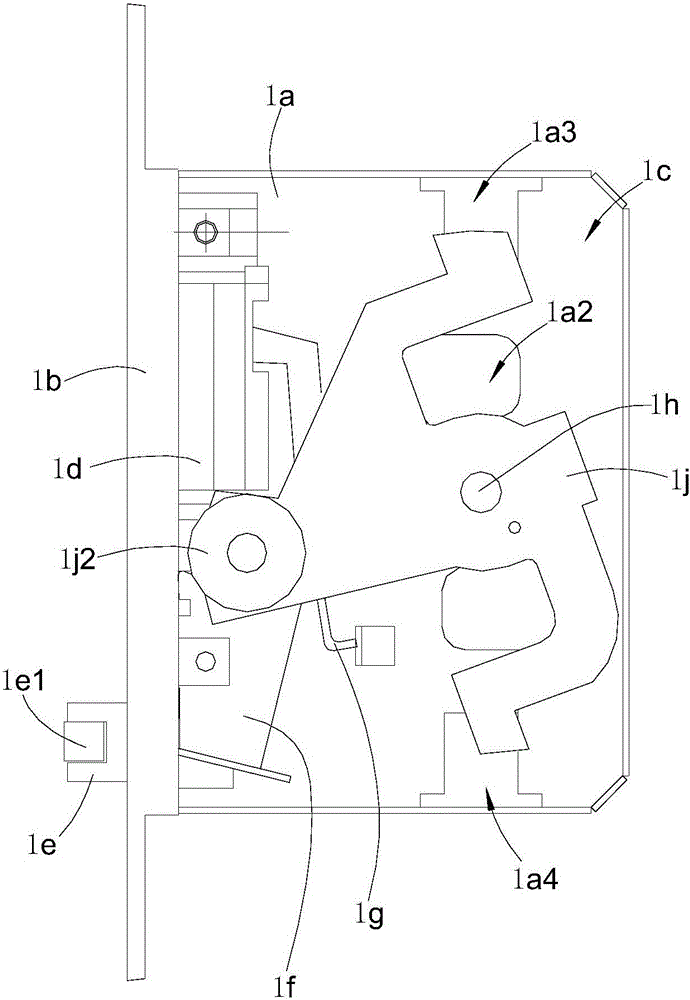

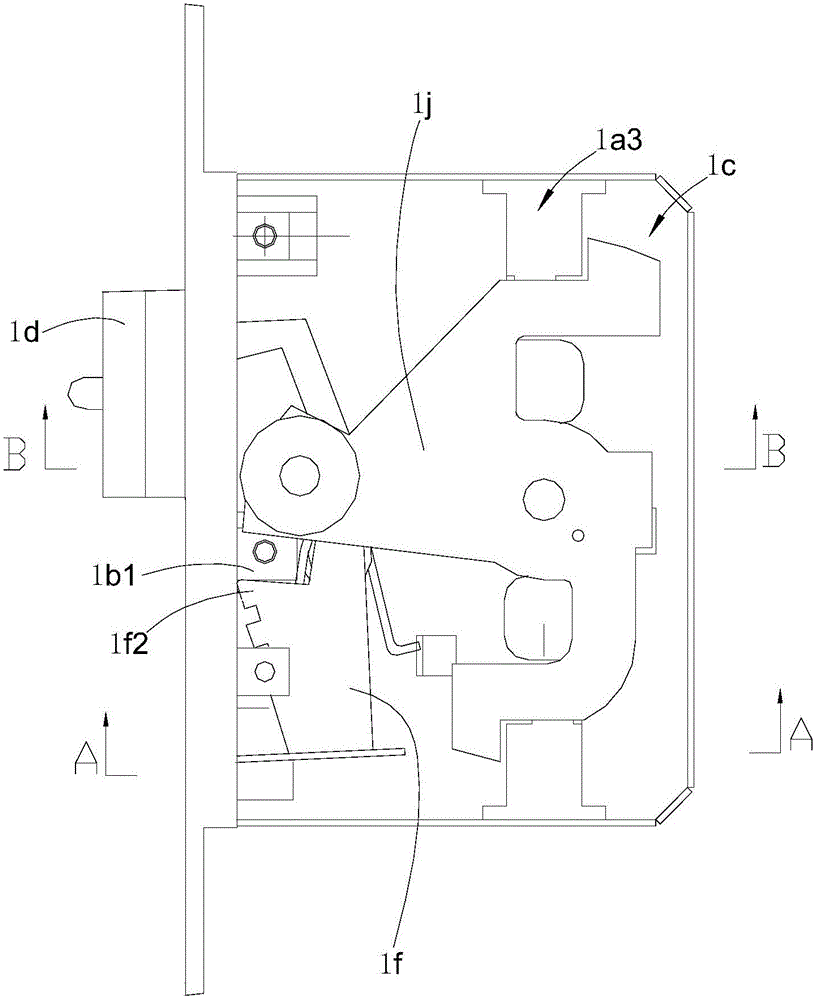

[0046] Such as Figures 1 to 8 shown

[0047] The handle lock body 1 includes a shell 1a, a side plate 1b, a main bolt 1d and an auxiliary bolt 1e, the shell 1a is composed of front and rear half shells, the left side of the shell 1a is open, and the side plate 1b is fixed on the shell 1a The side plate 1b closes the inside of the shell 1a to form a cavity 1c, and the side plate 1b is respectively provided with through holes for the rotation of the main bolt 1d and the auxiliary bolt 1e.

[0048] The inside of the main lock tongue 1d is hollow and the right end is open. The right edge of the rear side of the main lock tongue 1d extends with a first rotating shaft 1d1. The main locking tongue 1d is hinged between the first rotating shaft 1d1 and the upper part of the side plate 1b. The axis of the first rotating shaft 1d1 Consistent with the length direction of the side plate 1b, the main lock tongue 1d can be rotated into the cavity 1c along the first rotating shaft 1d1, and the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap