Treatment method of gibberellin production wastewater

A technology for producing wastewater and treatment method, applied in the field of environmental engineering, can solve the problems of complex gibberellin wastewater composition, reduction of pollutants in water, farmland soil pollution, etc., so as to reduce one-time investment and operating costs, reduce emissions, and avoid The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

[0032] Example.

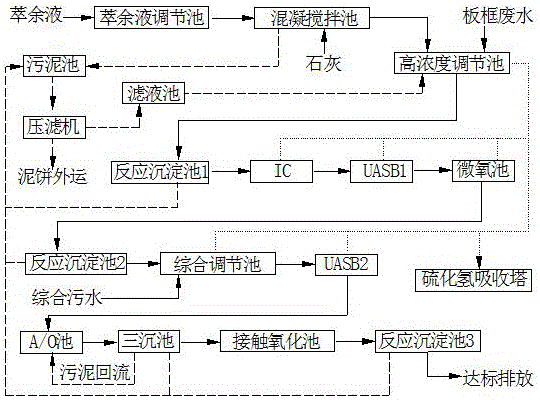

[0033] A kind of gibberellin production wastewater treatment process, such as figure 1 Shown, the processing method of gibberellin production waste water, comprises the following steps:

[0034] 1) The raffinate wastewater enters the raffinate adjustment tank to adjust the water quality and quantity, and then pumps it into the coagulation mixing tank through pipelines. Lime is added to the coagulation mixing tank to adjust the pH to 9.5. After mechanical stirring and precipitation, a large amount of sulfate can be removed, and the pretreatment of the raffinate is completed.

[0035] 2) The pretreated raffinate and high-concentration wastewater are mixed in the high-concentration regulating tank to balance and stabilize the water quality and quantity, and then enter the reaction sedimentation tank 1. The reaction sedimentation tank is composed of a rea

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap