High-pressure jet water face operating device

A kind of operation equipment and high-pressure jet technology, which is applied in the field of high-pressure jet water surface operation equipment, can solve the problems of low efficiency and achieve the effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

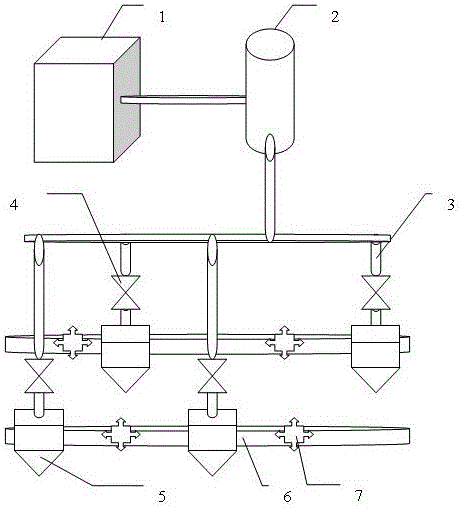

[0016] Attached below figure 1 Examples further illustrate the present invention

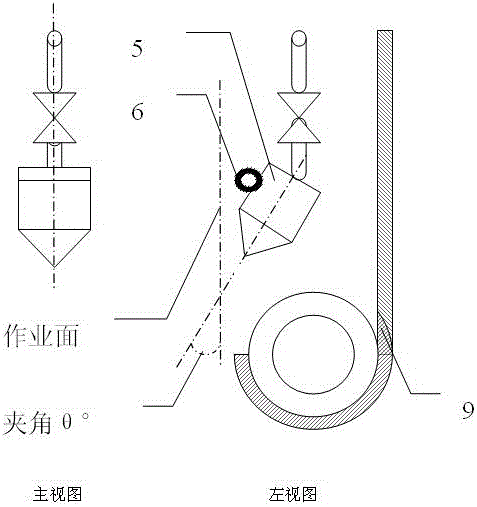

[0017] The present invention is an equipment combination of a distributed equipment operation system. The high-pressure water generator (1) generates the high-pressure water required for work, and stores it in the high-pressure water storage device (2) through a controllable pipeline. Automatic or manual control The high-pressure water control valve (4) makes the high-pressure water in the high-pressure water storage (2) reach the high-pressure water cutting head (5) by connecting the controllable pipelines and connecting pipes (3) of each section, and is sprayed by the nozzle. The high-speed, high-pressure jet water shoots to the working point to achieve the purpose of the operation.

[0018] The high-pressure water cutting head (5) and force balancer (7) are distributed on the connector (6) in an array, and are given corresponding working positions and postures to maintain an appropriate distanc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap