Test device for simulating sectional shield excavation

A test device and segmented technology, which is applied in the field of underground engineering, can solve problems such as cumbersome operation, and achieve the effects of accurate data, convenient and stable operation, and resistance to compression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

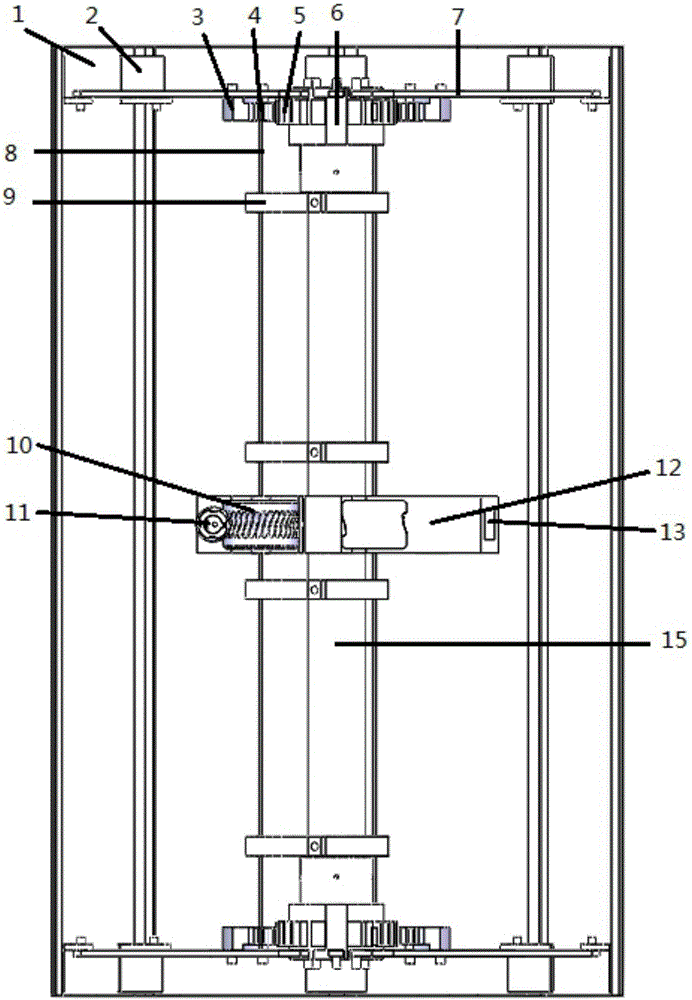

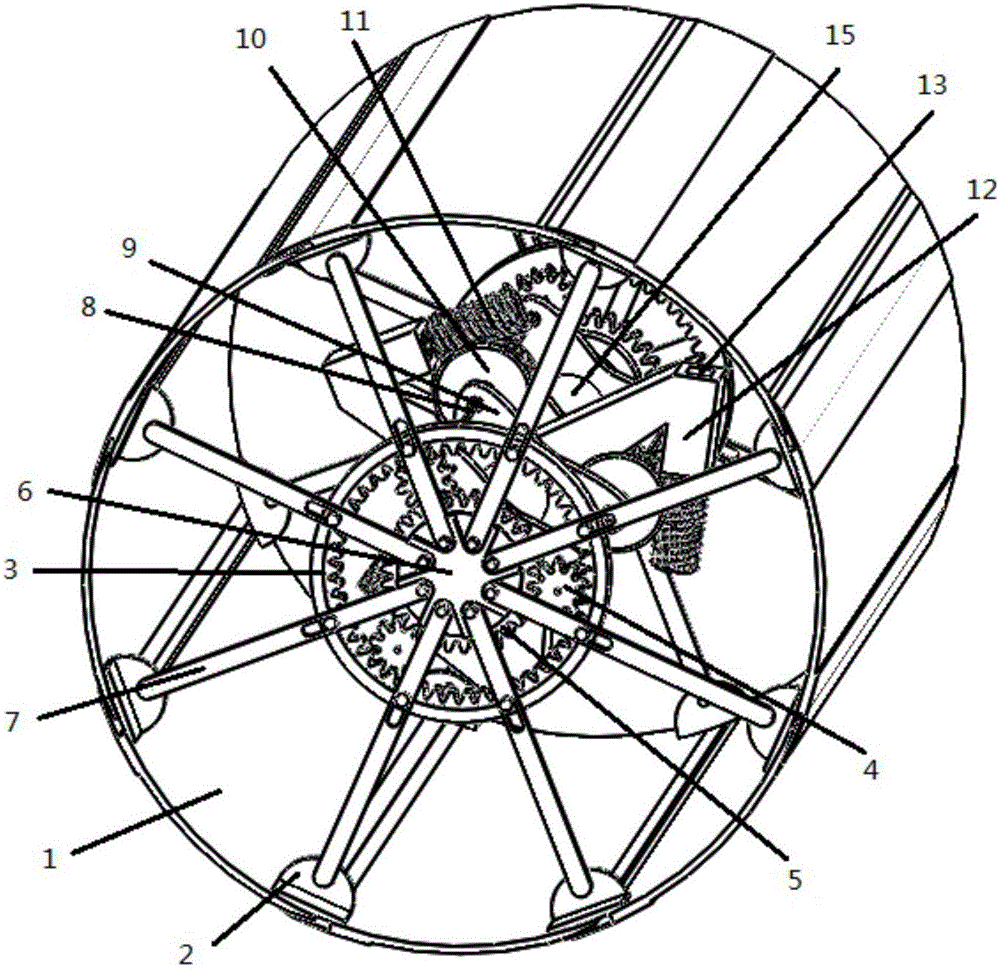

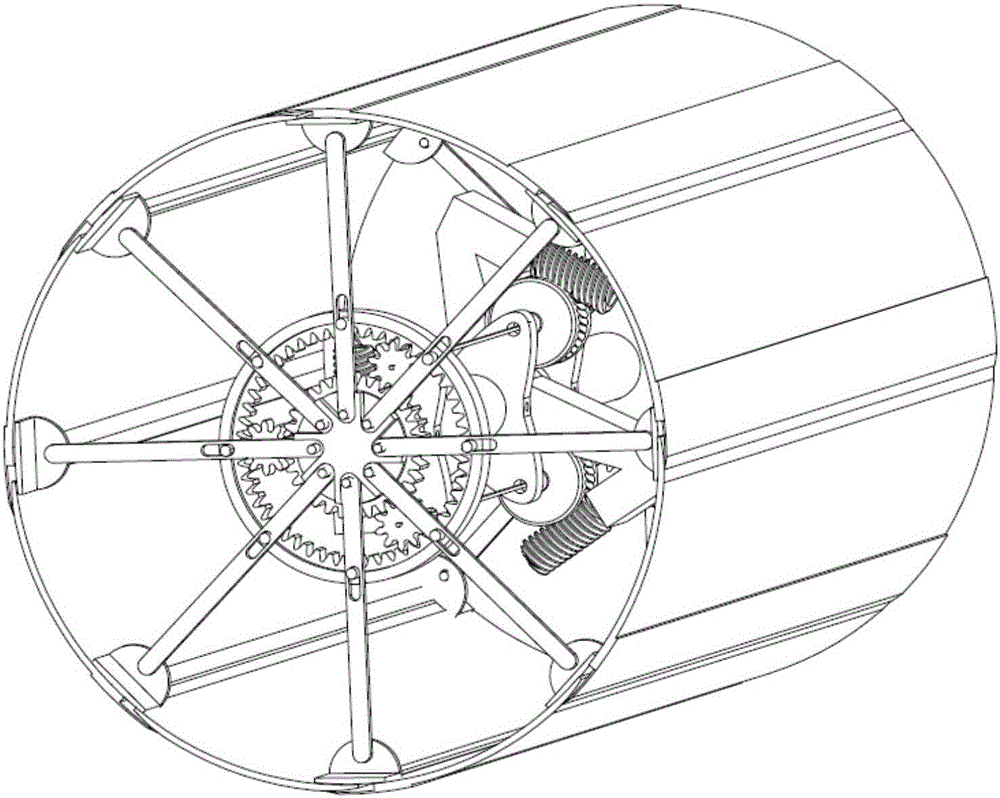

[0028] Such as Figure 1~3 As shown, the present invention provides a specific embodiment of a test device for simulating segmental excavation of a shield machine, which includes several unit shield machines connected in sequence, and each unit shield machine includes a drive control unit, two Rotate the contraction mechanism and the outer frame 1, the drive control unit includes three drive motors 13, and connect the worm gear 10 screw at the front end of each drive motor 13, and connect the wires at the rear end; The spacing is fixed around the center of the main shaft; the outer frame 1 is composed of eight arc-shaped pieces connected in sequence, and the two adjacent arc-shaped pieces are respectively connected by the fixed piece 2, and there is movement between the two adjacent arc-shaped pieces Clearance; the two ends of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap