Bottom plate lacquering device for lacquer painting manufacturing

A technology for function and lacquer painting, which is applied in the field of floor painting devices for lacquer painting production, can solve the problems of low work efficiency, high processing cost, and high technical requirements for labor, and achieves short working time, high working efficiency, and paint saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

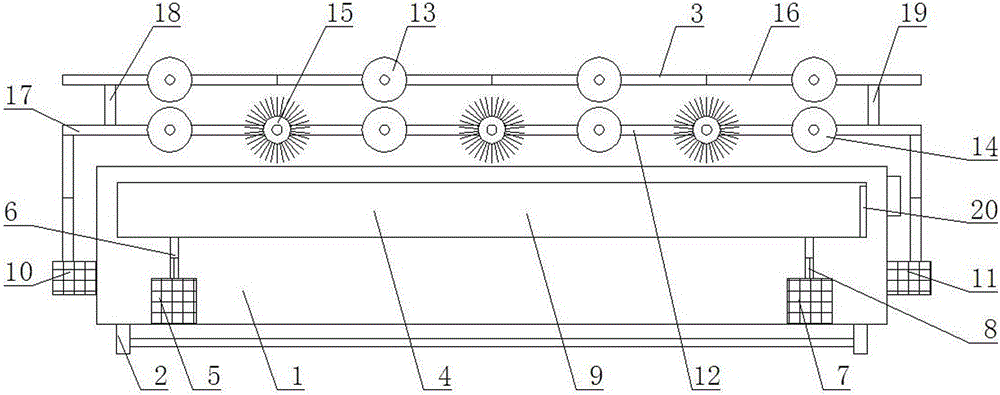

[0013] Such as figure 1 Shown, a kind of lacquer painting production is used floor paint device, comprises outer box body 1, support frame 2, elevating painting device 3, elevating paint box 4, and the bottom end of described outer box body 1 is supported by support frame 2, The interior of the outer box body 1 is equipped with a lifting paint box 4, and the upper end of the outer box body 1 is equipped with a lifting paint device 3; The lifting shaft 8 and the inner box body 9 are composed; the left hydraulic driver 5 is installed on the left side of the bottom end of the outer box body 1, and the upper end is connected to the left side of the bottom end of the inner box body 9 through the left hydraulic lifting shaft 6; the right hydraulic driver 7 The device is on the right side of the inner bottom of the outer box body 1, and the upper end is connected to the right side of the bottom end of the inner box body 9 through the right hydraulic lifting shaft 8; Four upper clamping

Embodiment 2

[0015] Such as figure 1 As shown, the mounting frame 12 is composed of an upper frame body 16, a lower frame body 17, a left connecting frame 18, and a right connecting frame 19; the upper frame body 16 and the lower frame body 17 are fixed by the left connecting frame 18 and the right connecting frame 19 connect.

Embodiment 3

[0017] Such as figure 1 As shown, a liquid level detector 20 is installed inside the inner box body 9 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap