Treatment method of landfill leachate

A treatment method and leachate technology, applied in filtration treatment, sludge treatment, water/sewage treatment, etc., can solve problems such as poor treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

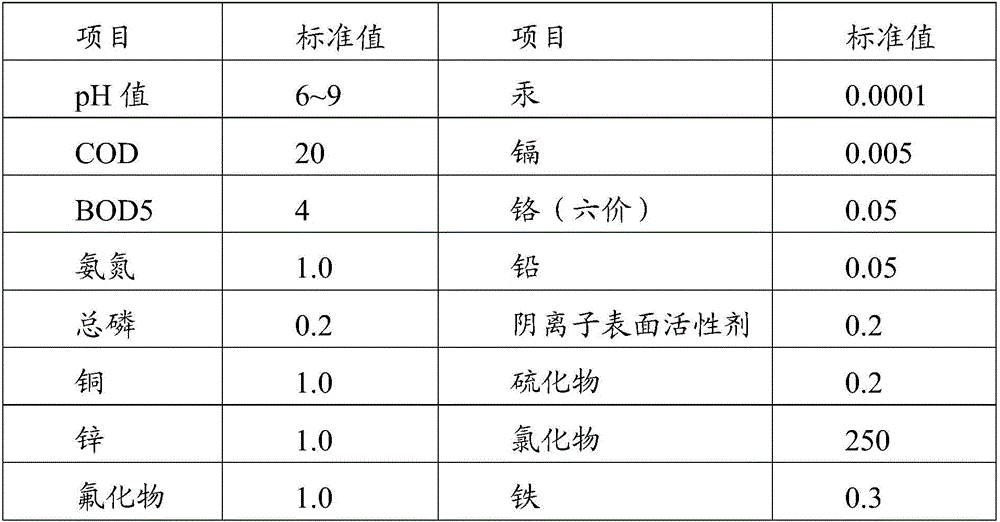

[0074] This embodiment deals with leachate from a hazardous waste landfill. After testing, the water quality of the leachate from the hazardous waste landfill is shown in Table 2 below.

[0075] Table 2: Water quality of leachate from a hazardous waste landfill (unit: mg / L, except pH value)

[0076]

[0077] The processing method of the hazardous waste landfill leachate of the present embodiment comprises the following steps:

[0078] Add 30mg of flocculant PAC and 10mg of coagulant aid PAM to 1L of hazardous waste landfill leachate, stir and stand to obtain a mud-water mixture, and separate mud-water by pressure filtration to obtain the first treatment liquid and flocculated sludge.

[0079] Add sulfuric acid to the first treatment solution to a pH value of 2.15, then add 80 mg of 30% H 2 o 2 and 40mg of FeSO 4 , stirred evenly, and the reaction time was 30 minutes. After filtering, the second treatment liquid and the first sedimentation sludge were obtained. The measur

Embodiment 2

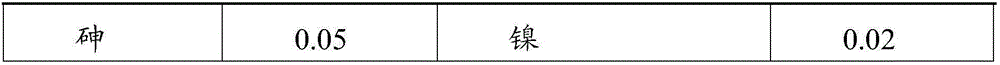

[0087] This embodiment deals with the leachate of a hazardous waste landfill. After testing, the water quality of the leachate of the hazardous waste landfill is shown in Table 3 below.

[0088] Table 3: Water quality of leachate from a hazardous waste landfill (unit: mg / L, except pH value)

[0089]

[0090] The processing method of the hazardous waste landfill leachate of the present embodiment comprises the following steps:

[0091] Add 30mg of flocculant PAC and 10mg of coagulant aid PAM to 1L of hazardous waste landfill leachate, stir and stand to obtain a mud-water mixture, and separate mud-water by pressure filtration to obtain the first treatment liquid and flocculated sludge.

[0092] Add sulfuric acid to the first treatment solution to a pH value of 2.3, then add 80 mg of 30% H 2 o 2 and 40mg of FeSO 4 , stirred evenly, and the reaction time was 30 minutes. After filtering, the second treatment liquid and the first sedimentation sludge were obtained. The measure

Embodiment 3

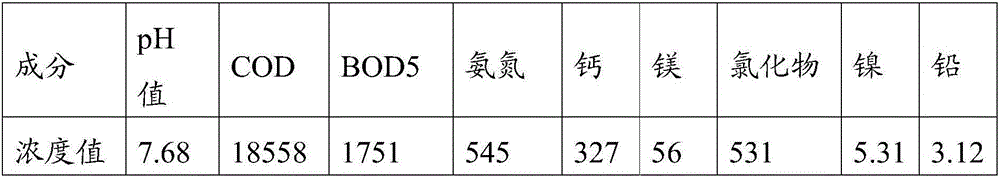

[0100] This embodiment deals with leachate from a hazardous waste landfill. After testing, the water quality of the leachate from the hazardous waste landfill is shown in Table 4 below.

[0101] Table 4: Water quality of leachate of a hazardous waste landfill (unit: mg / L, except pH value)

[0102]

[0103] The processing method of the hazardous waste landfill leachate of the present embodiment comprises the following steps:

[0104] Add 30mg of flocculant PAC and 10mg of coagulant aid PAM to 1L of hazardous waste landfill leachate, stir and stand to obtain a mud-water mixture, and separate mud-water by pressure filtration to obtain the first treatment liquid and flocculated sludge.

[0105] Add sulfuric acid to the first treatment solution to a pH value of 2.65, then add 80 mg of 30% H 2 o 2 and 40mg of FeSO 4 , stirred evenly, and the reaction time was 30 minutes. After filtering, the second treatment liquid and the first sedimentation sludge were obtained. The COD valu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap