Sowing apparatus having automatic soil-filling and roll-pressing function

A seeding device and automatic technology, which is applied to the parts of the planter and the machine for interval quantitative sowing, etc., can solve the problems of poor seedling emergence, many operation steps, and reduced seeding efficiency, etc., and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

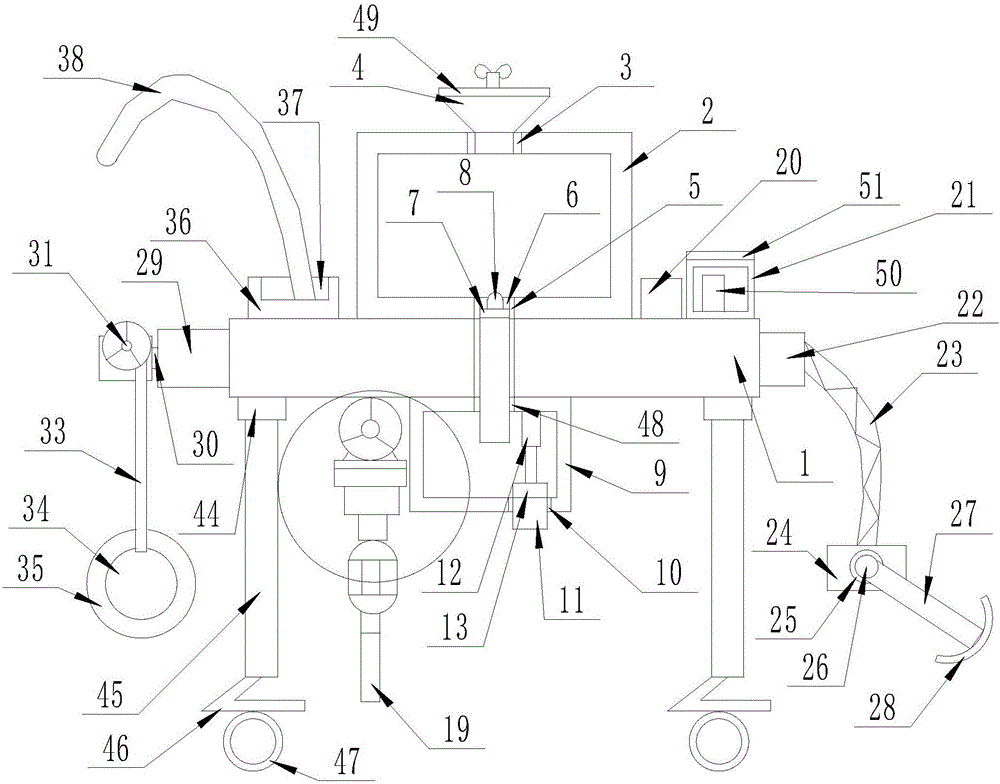

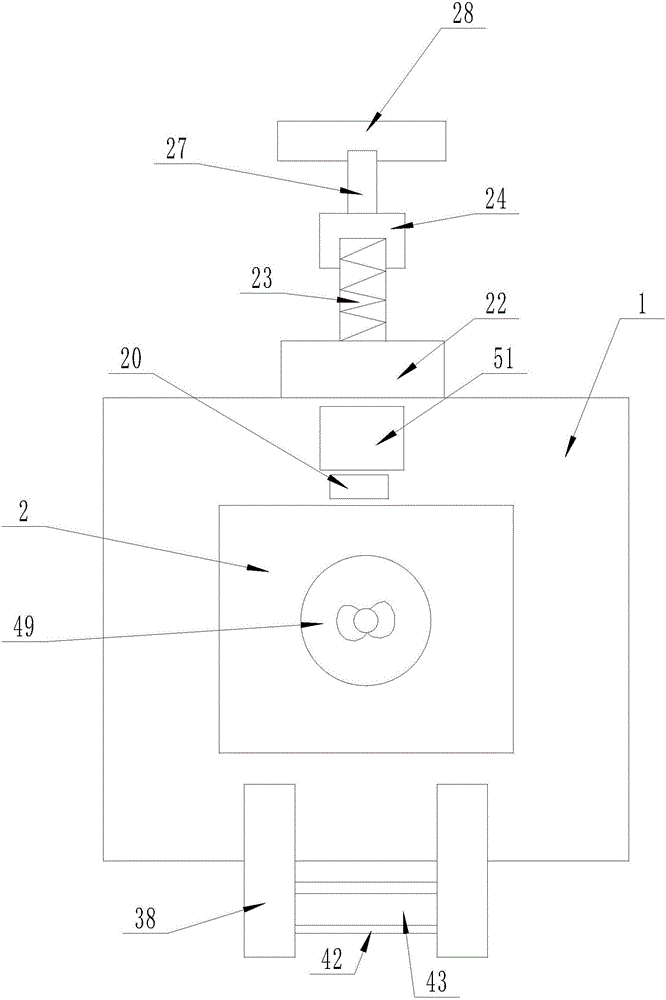

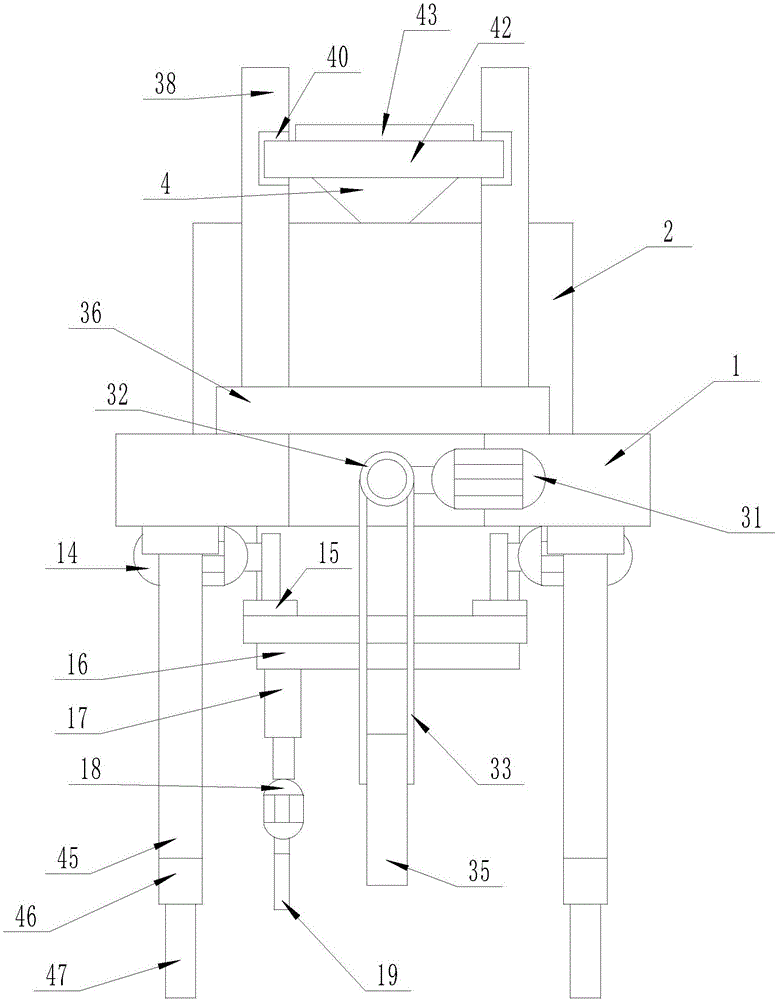

[0020] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a seeding device with automatic filling and rolling includes a rectangular base (1), an automatic seeding mechanism is provided at the center of the upper surface of the rectangular base (1), and the rectangular base (1) Two opposite side surfaces are provided with an automatic filling mechanism, the side surface of the rectangular base (1) is provided with a rolling mechanism, and the four corners of the lower surface of the rectangular base (1) are provided with a moving mechanism, and the rectangular base (1) is provided with a moving mechanism. The upper surface of the base (1) and the rear side of the automatic seeding mechanism are provided with a push-pull mechanism, and the automatic seeding mechanism consists of a bearing box (2) fixedly connected to the center of the upper surface of the rectangular base (1) 2) The inlet (3) on the upper surfac

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap