Wireless cloth breaker

A fabric breaking machine and wireless technology, applied in the field of wireless fabric breaking machines, can solve problems such as damage, contact wear, safety accidents, etc., to avoid electric shock events, protect from damage, and ensure reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

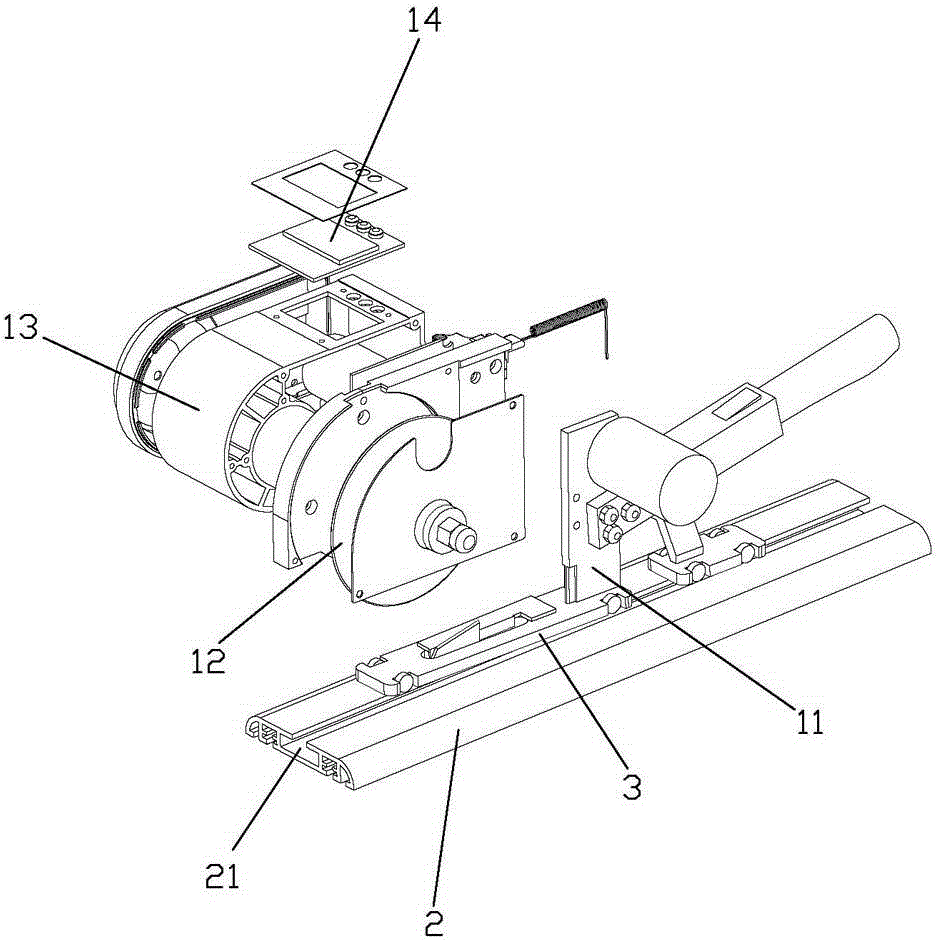

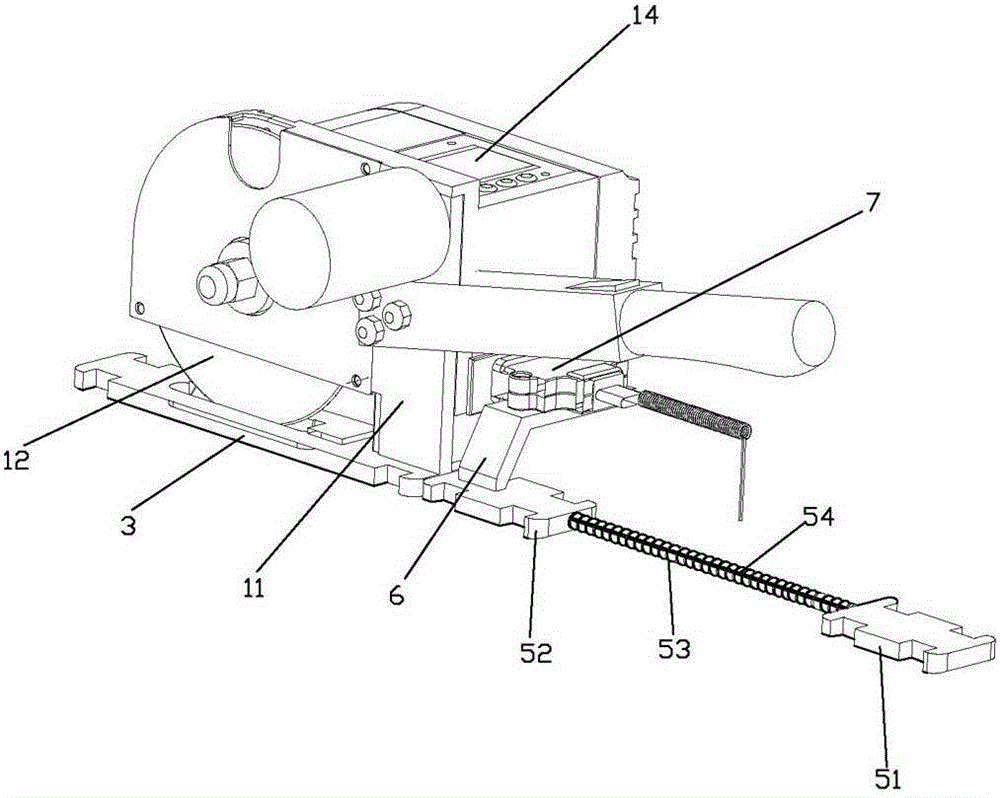

[0018] Such as Figure 1-6 As shown, a wireless cloth cutting machine includes a host 1 and a slide rail 2, the host 1 includes a frame 11, a cloth cutting knife 12, a motor 13 and a controller 14, and a slide is provided at the bottom of the frame 11. Block 3, the slider 3 is accommodated in the chute 21 of the slide rail 2, characterized in that: a buffer mechanism 5 is provided at one end of the chute 21, and the buffer mechanism 5 is connected to a power input connector 7 through the connecting plate 6 connection, the power input connector 7 is located above the slider 3, and the charging connector 8 is arranged on the rear side of the frame 11 corresponding to the power input connector 7, and there is also a suction connector between the charging connector 8 and the power input connector 7. A combination device; a capacitor charging circuit is also set in the host 1, the input of the capacitor charging circuit is connected to the charging joint 8, and the output of the capac

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap