Linear generator test platform

A technology of linear generator and test platform, applied in the direction of motor generator test, measurement of electricity, measurement device, etc., can solve the problems of small test range, poor versatility, complex structure, etc., and achieves wide test range, convenient installation, and measurement accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032] The present invention will be further described below in conjunction with the drawings and specific embodiments.

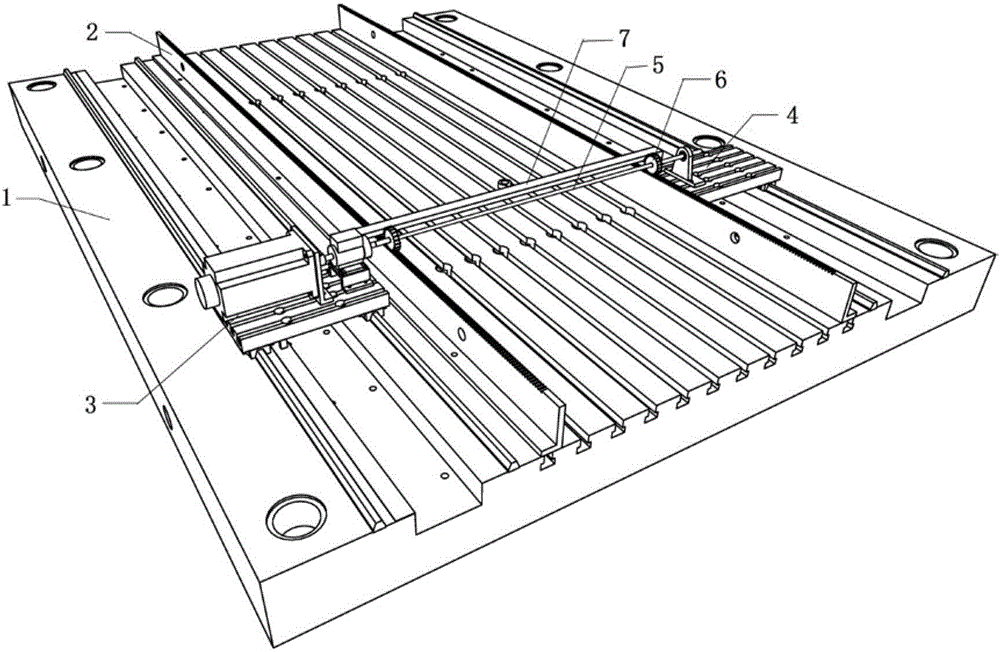

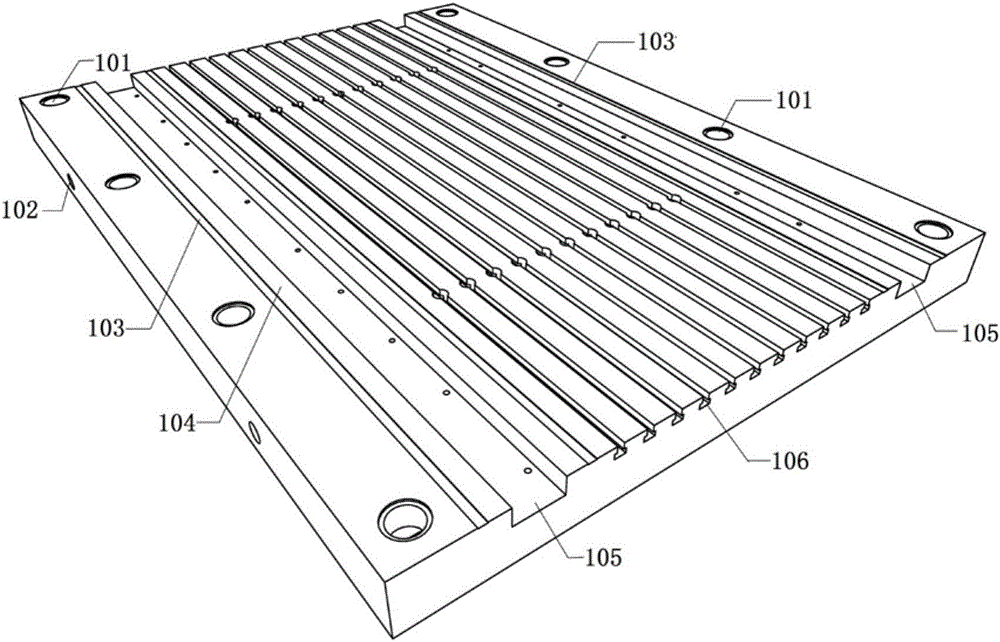

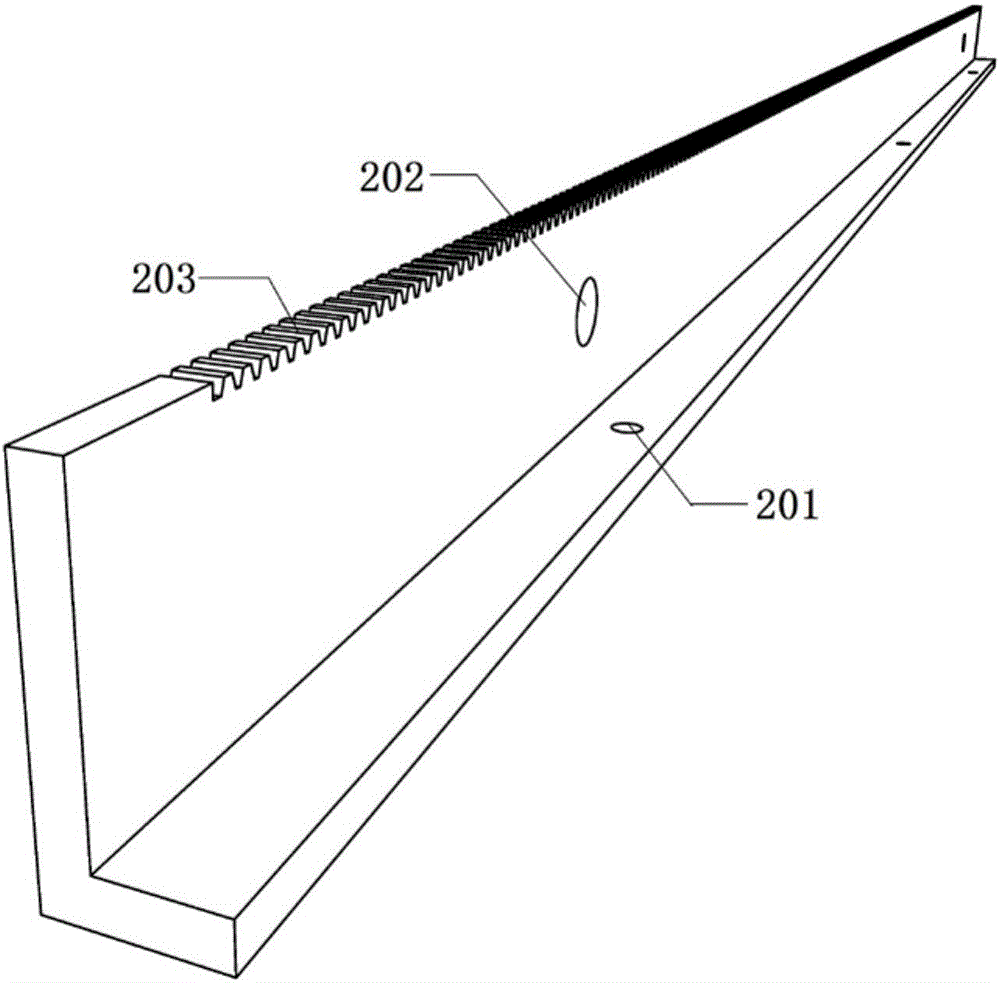

[0033] Such as figure 1 , figure 2 , Figure 4 with Figure 5 As shown, the linear generator test platform of the present invention includes a floor iron 1, a rack 2, a driving platform 3, a driven platform 4, a shaft 5, a gear 6, and a drag beam 7. The floor iron 1 is horizontally fixed to the ground through floor iron installation holes, two sets of guide rails 103 are installed on both sides of the floor iron 1 in parallel, and the floor iron 1 and the guide rail 103 are welded and fixed. The driving platform 3 and the driven platform 4 are respectively located on the guide rails 103 on both sides of the floor iron 1; the rack 2 is located between the driving platform 3 and the driven platform 4, and is fixed in parallel on the floor iron 1; Straddling between the driving table 3 and the driven table 4, the two ends of the shaft 5 are respectively connected w

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap