Multi-rotor-difference cascade permanent magnetic speed regulating device

A permanent magnet speed regulation and differential cascading technology, applied in electromechanical devices, permanent magnet clutches/brakes, electrical components, etc., can solve problems such as large axial pulling force, achieve high reliability, easy installation and debugging, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0049] Example one:

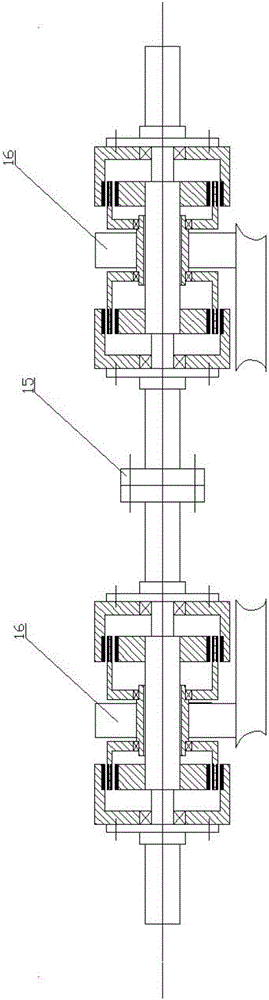

[0050] Such as Figure 1-3 As shown, the multi-slip cascade type permanent magnet speed control device includes a plurality of two-stage speed control modules 16, a plurality of two-stage speed control modules 16 are connected in series, and two adjacent two-stage speed control modules 16 pass between The coupling 15 is connected;

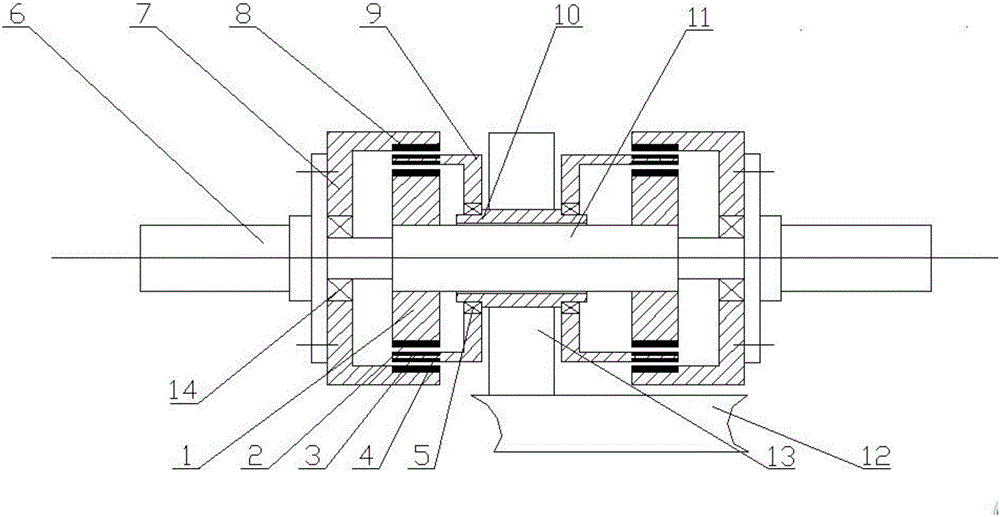

[0051] The two-stage speed control module 16 includes two symmetrically cascaded single-stage speed control modules, the structure of which is symmetrical about the left and right vertical center lines;

[0052] The single-stage speed regulation module includes an active rotor assembly, a speed regulation rotor assembly and a driven rotor assembly;

[0053] The active rotor assembly is composed of an end shaft 6, an outer sleeve 7, a good conductor B8 and a bearing B14; the end shaft 6 is a stepped shaft, and its largest diameter end is rigidly connected to the outer sleeve 7 by bolts or keys The outer sleeve 7 is a cylindrical structu

Example Embodiment

[0058] Embodiment two:

[0059] Such as figure 1 , 4 , 5, the multi-slip cascade permanent magnet speed control device includes a plurality of two-stage speed control modules 16, a plurality of two-stage speed control modules 16 are connected in series, and one of the two adjacent two-stage speed control modules 16 Are connected by coupling 15;

[0060] The two-stage speed control module 16 includes two symmetrically cascaded single-stage speed control modules, the structure of which is symmetrical about the left and right vertical center lines;

[0061] The single-stage speed regulation module includes an active rotor assembly, a speed regulation rotor assembly and a driven rotor assembly;

[0062] The active rotor assembly is composed of an end shaft 6, an outer sleeve 7, a permanent magnet B4 and a bearing B14; the end shaft 6 is a stepped shaft, and its largest diameter end is rigidly connected to the outer sleeve 7 by bolts or keys The outer sleeve 7 is a cylindrical structure, it

Example Embodiment

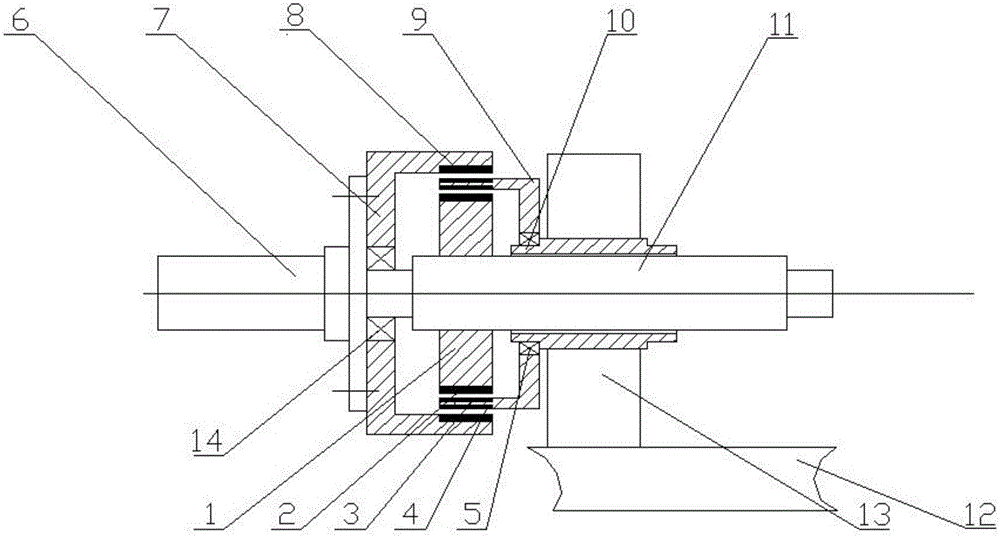

[0067] Embodiment three:

[0068] Such as figure 2 , 4 As shown, the multi-slip cascade permanent magnet speed control device includes a two-stage speed control module 16 with the left end shaft 6 as the input shaft and the right end shaft 6 as the output shaft.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap