Multifunctional heat pump system

A heat pump system and multi-functional technology, applied in heat pumps, lighting and heating equipment, damage protection, etc., can solve problems such as frequent start-up of compressors, unstable working conditions of heat pump units, overheating of compressor motors, etc., and achieve hot gas bypass Mixed energy adjustment, realize hot gas bypass energy adjustment function, and avoid the waste of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

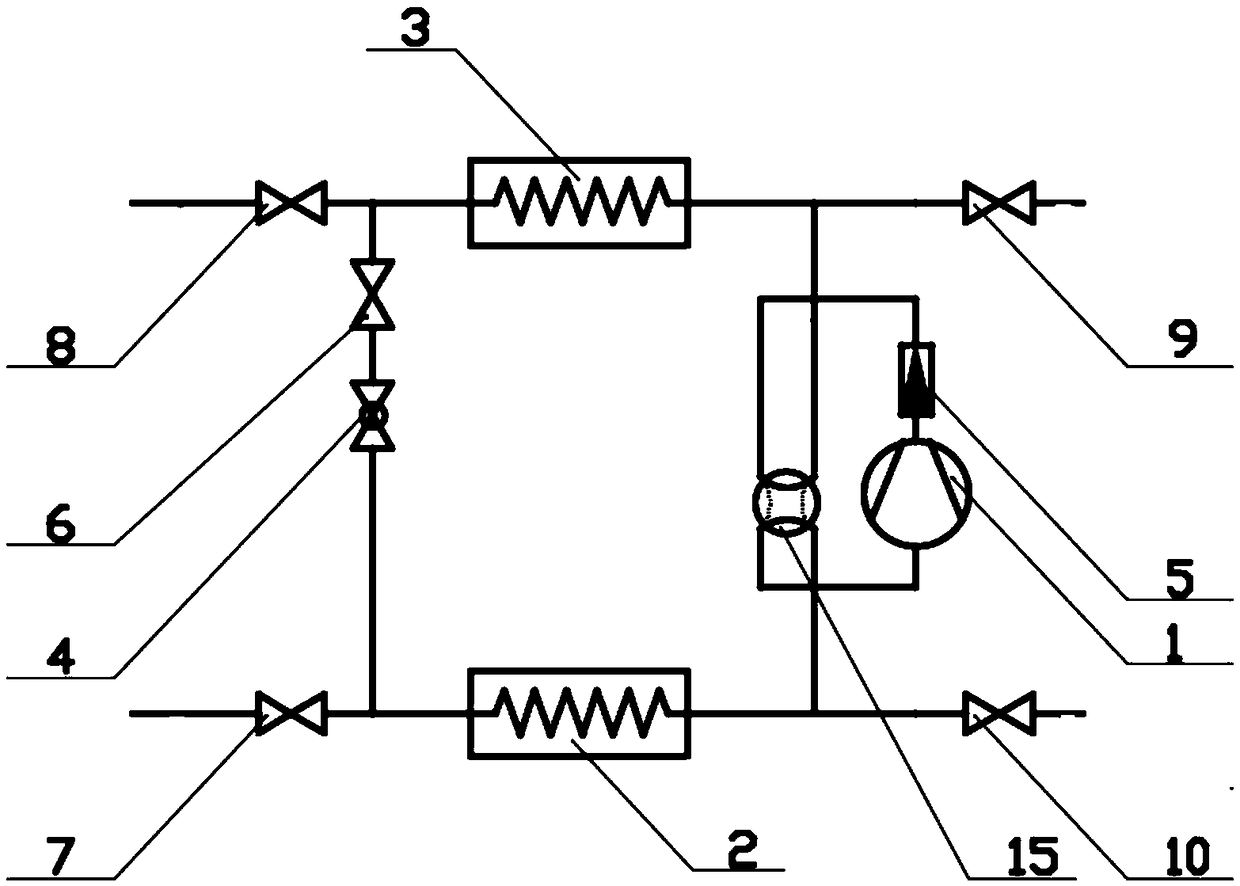

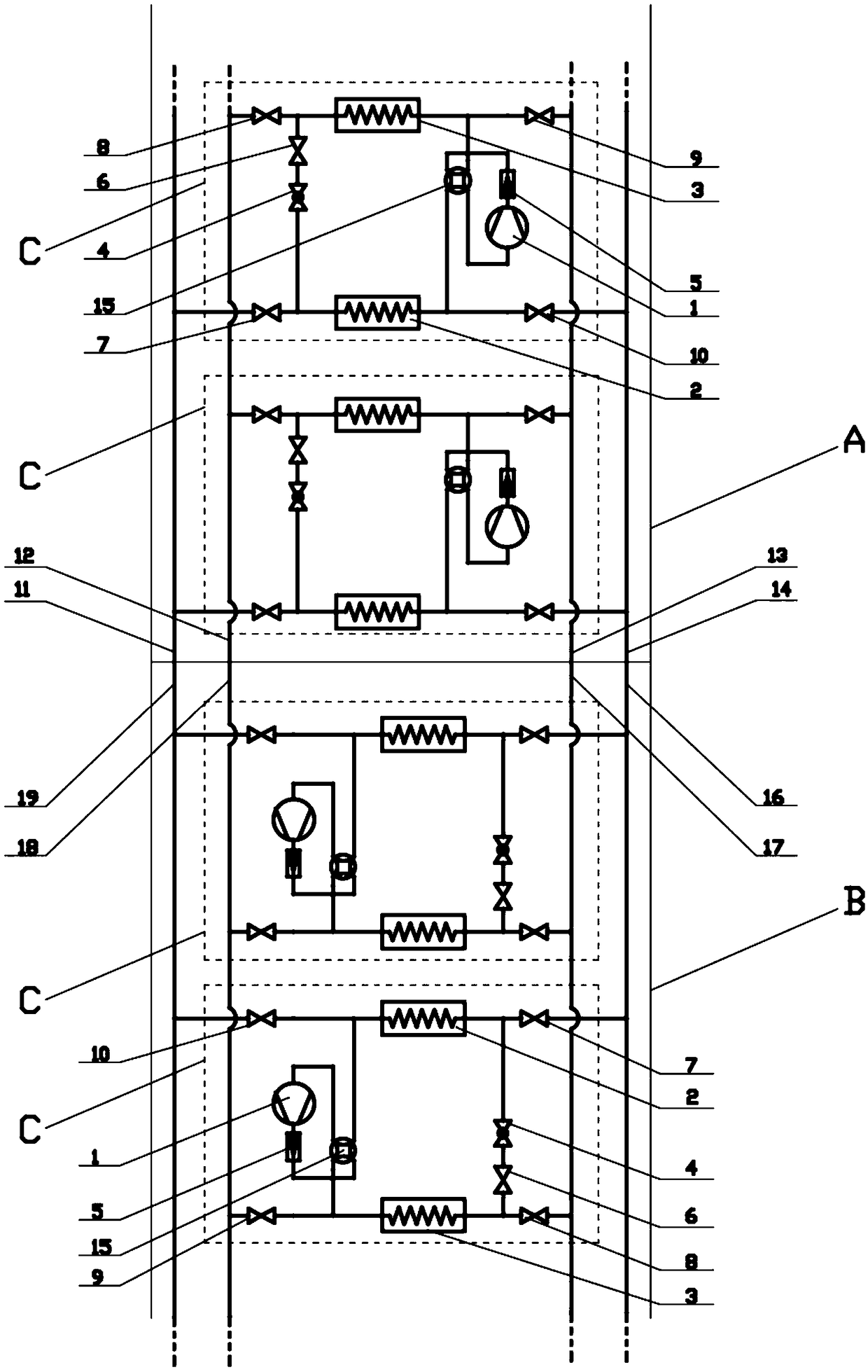

[0029] Embodiment 1: Take the heat pump module in the second heat pump unit B for the cooling process, the heat pump module in the first heat pump unit A performs the bypass adjustment process as an example, that is, in the second heat pump unit B as the cooling process The refrigeration compressor in the heat pump module is running, and the refrigeration compressor in the heat pump module A in the first heat pump unit A of the bypass adjustment process is stopped. The bypass adjustment process includes: (1), hot air bypass to the energy-regulated thermodynamic cycle at the suction end of the refrigeration compressor; (2) hot air bypass to the energy-regulated thermodynamic cycle at the entrance of the indoor heat exchanger; (3), hot air bypass The energy mixed at the suction end of the compressor and the inlet of the indoor heat exchanger adjusts the thermodynamic cycle. The first valve 7, the second valve 8, the third valve 9 and the fourth valve 10 in the heat pump modules in t

Example Embodiment

[0035] Embodiment 2: Take the second heat pump unit B for the heating process, the first heat pump unit A for the bypass adjustment process or the outdoor heat exchanger defrosting process as an example, that is, the second heat pump unit as the heating process The refrigeration compressor in the heat pump module in B operates, and the refrigeration compressor in the heat pump module in the heat pump module A in the first heat pump unit A is stopped as a bypass adjustment process or an outdoor heat exchanger defrosting process. The bypass and defrost process are: (1) hot gas bypass to the energy-regulated thermodynamic cycle at the suction end of the refrigeration compressor; (2) hot gas bypass to the energy-regulated thermodynamic cycle at the entrance of the outdoor heat exchanger; (3) hot gas bypass The energy mix at the suction end of the compressor and the entrance of the outdoor heat exchanger to adjust the thermodynamic cycle; (4) Defrost cycle of the outdoor heat exchanger.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap