Anti-cutting safety glove

A technology of anti-cutting and gloves, applied in the field of life, can solve the problems of insufficient protection, poor heat resistance, and small friction, etc., and achieve the effect of simple structure, convenient operation, and improved friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

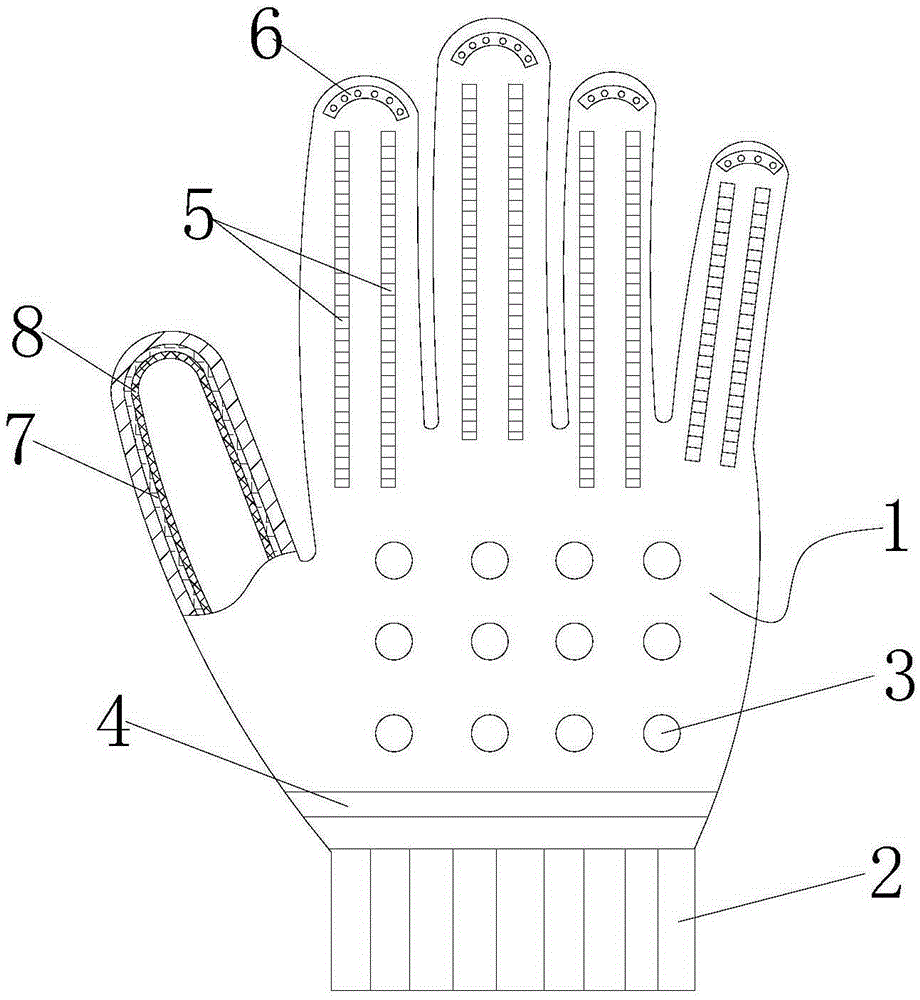

[0013] see figure 1 , figure 1 It is a structural schematic diagram of the present invention.

[0014] A cut-resistant safety glove, comprising a glove main body 1, a shrink sleeve 2 is provided on one end of the glove main body 1, a plurality of anti-skid bumps 2 on the glove main body 1 and on the outer surface corresponding to the palm of the hand, the glove main body 1. There are several fluorescent strips 4 on the side wall, wherein the width of the fluorescent strips 4 is 1 mm to 5 mm, and the number of fluorescent strips 4 is 1 to 5, which is convenient for workers to quickly find gloves at n

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap