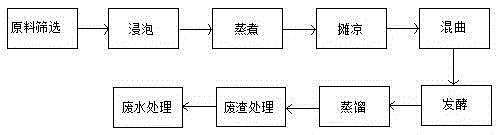

Brewing process for Baijiu

A technology and technology of liquor, which is applied in the preparation of alcoholic beverages, etc., can solve the problems such as the taste of liquor is not mild enough and the cost of liquor manufacturing, and achieve the effects of no turbidity, good transparency, and unique taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0039] 1) Screening of raw materials: organic rice and sorghum are used as raw materials, and the mass parts of each raw material are:

[0040] Organic Rice: 96%,

[0041] Sorghum: 2.5%;

[0042] 2) Soaking: Soak the raw materials in warm water, the temperature of the soaking water is 60°C, and the soaking time is 5 hours;

[0043] 3) Cooking: Put the soaked raw materials into the cooking pot, and use the steam generated by the electric heating steam boiler to cook with a cover. The specific operation of cooking is: drain the soaked raw materials and pour them into the cooking pot. Level the raw materials in the cooking pot, turn on the steam for cooking, pour cold water into the cooking pot for the first time after cooking for 25 minutes, continue cooking for 10 minutes, pour cold water into the cooking pot for the second time, and at the same time, pour the raw materials in the cooking pot Stir and stir, and then flatten the raw materials for cooking. After the steam is satur

specific Embodiment 2

[0060] 1) Screening of raw materials: organic rice and sorghum are used as raw materials, and the mass parts of each raw material are:

[0061] Organic Rice: 94%,

[0062] Sorghum: 4.5%;

[0063] 2) Soaking: Soak the raw materials in warm water, the temperature of the soaking water is 65°C, and the soaking lasts for 8 hours;

[0064] 3) Cooking: Put the soaked raw materials into the cooking pot, and use the steam generated by the electric heating steam boiler to cook with a cover. The specific operation of cooking is: drain the soaked raw materials and pour them into the cooking pot. Level the raw materials in the cooking pot, turn on the steam for cooking, pour cold water into the cooking pot for the first time after cooking for 25 minutes, continue cooking for 10 minutes, pour cold water into the cooking pot for the second time, and at the same time, pour the raw materials in the cooking pot Stir and stir, and then flatten the raw materials for cooking. After the steam is sat

specific Embodiment 3

[0081] 1) Screening of raw materials: organic rice and sorghum are used as raw materials, and the mass parts of each raw material are:

[0082] Organic Rice: 92%,

[0083] Sorghum: 6.5%;

[0084] 2) Soaking: soak the raw materials in warm water, the temperature of the soaking water is 70°C, and soak for 10 hours;

[0085] 3) Cooking: Put the soaked raw materials into the cooking pot, and use the steam generated by the electric heating steam boiler to cook with a cover. The specific operation of cooking is: drain the soaked raw materials and pour them into the cooking pot. Level the raw materials in the cooking pot, turn on the steam for cooking, pour cold water into the cooking pot for the first time after cooking for 25 minutes, continue cooking for 10 minutes, pour cold water into the cooking pot for the second time, and at the same time, pour the raw materials in the cooking pot Stir and stir, and then flatten the raw materials for cooking. After the steam is saturated, cove

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap