Rapid verification method and device for non-dismountable sulfur hexafluoride density relay

A technology of density relay and sulfur hexafluoride, which is applied in the direction of measuring devices, circuit breaker testing, instruments, etc., to reduce safety hazards and shorten time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the embodiments and with reference to the accompanying drawings.

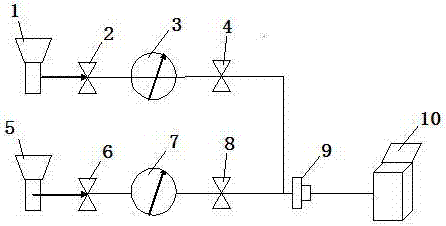

[0021] Such as figure 1 As shown, this embodiment is a quick calibration method without disassembling the sulfur hexafluoride density relay, and the equipment used in the quick calibration method in this embodiment is a quick calibration device without disassembling the sulfur hexafluoride density relay. In this embodiment, a quick calibration device for a sulfur hexafluoride density relay without disassembly includes: the first sulfur hexafluoride gas insulation device 1, the first gas sampling joint and valve 2, and the concentrated arrangement of sulfur hexafluoride gas density relays on the platform The first density relay 3, the first density relay check valve 4, the second sulfur hexafluoride gas insulation equipment 5, the second gas sampling joint and valve 6, the second sulfur hexafluoride gas density relay on the centraliz

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap