Sliding door upper rail based on building steel beam structure

A technology for sliding doors and steel beams, which is applied to building structures, buildings, door/window accessories, etc. It can solve problems such as the linear increase of manual labor, the difficulty of installing upper rails on sliding doors, and the inability to meet the needs of steel beam structure installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

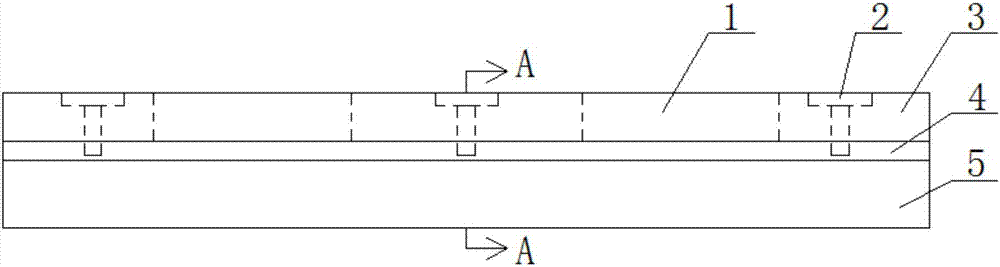

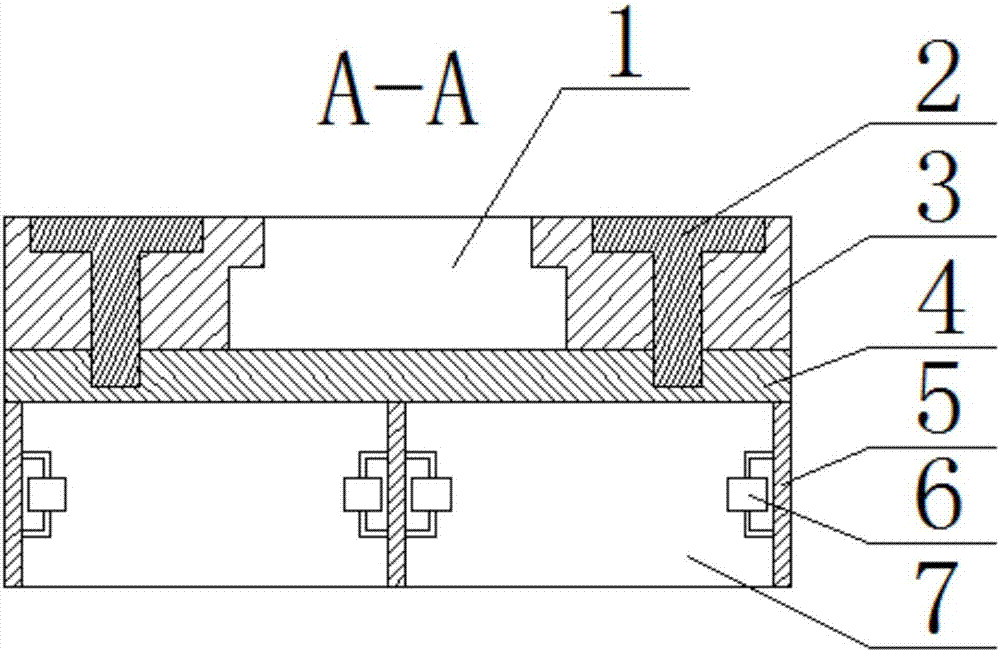

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

[0013] Such as Figure 1-2 As shown, the upper rail of a sliding door based on a building steel beam structure described in this specific embodiment includes a permanent magnet 1, a fixing screw 2, a pressing plate 3, a base plate 4, a baffle plate 5, and a U-shaped groove 7; 3 is fixed on the top of the base plate 4 with fixing screws 2; there are two pressure plates 3, which are respectively located on both sides of the top of the base plate 4; permanent magnets 1 are arranged between the pressure plates 3; the permanent magnet 1 is stabilized on the base plate by the two pressure plates 3 4; the inside of the pressure plate 3 is provided with a countersunk hole, and the fixing screw 2 is locat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap