Method for assembling temporary small building spliced by paper universal components

A combination method and temporary technology, applied in the direction of small buildings, buildings, building components, etc., can solve the problems of space use efficiency and building use effect instability, installation and transportation are not very convenient, and small living room structures are self-heavy, etc. Achieve smoothness and comfort, convenient and fast installation, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The first temporary small building type:

[0085] 1. A temporary small building assembled from paper general components:

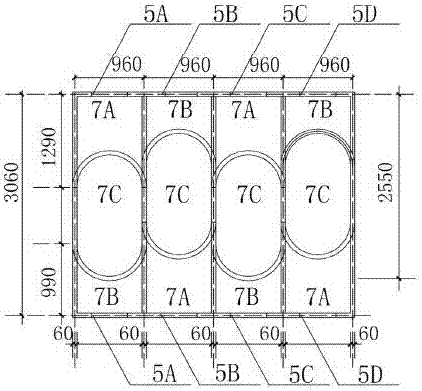

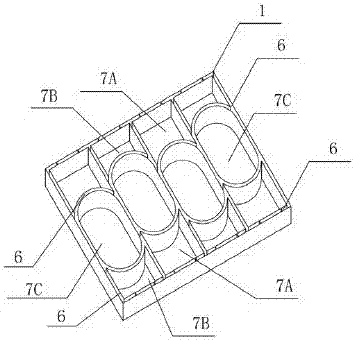

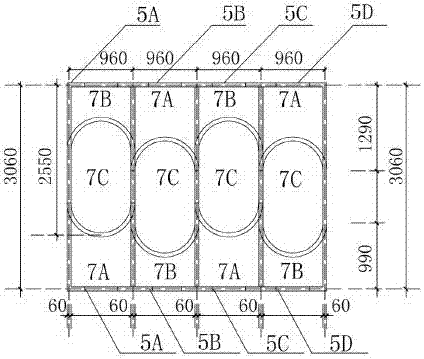

[0086] Such as image 3 , 4, 13, and 14, the frame of the splicing system structure of this apartment type is divided into four identical rectangular unit structures 5A, 5B, 5C, and 5D arranged in sequence, and the first groove 7A of 5A is attached to the front wall 3A; The second groove 7B of the first unit structure 5A of the house type, the third groove 7C of the first unit structure 5A and the first groove 7A area of the second unit structure 5B are the traffic area 9A of the first house type, which is composed of the corresponding The second papery common component a 4B1, the third papery common component a 4C1 and the first papery common component a4A1 form the floor of the first apartment type traffic area 9A; the first groove 7A area of the first unit structure 5A is the first The apartment-type workshop 10A is occupied by the worktable

Embodiment 2

[0116] The second temporary small building type:

[0117] 1. A temporary small building assembled from paper general components, the difference from Embodiment 1 is:

[0118] Such as image 3 , 4 , 15, and 16, the area of the third groove 7B of the second unit structure 5B of the apartment type, the area of the second groove 7B and the area of the third groove 7C of the third unit structure 5C are the traffic area 9B of the second apartment type, and the corresponding Two third paper general components a 4A1, 1 second paper general components a 4B1 form the floor of the second apartment type traffic area 9B; the first groove 7A area of the first unit structure 5A and the second unit structure 5B The second recessed area is the first workshop 10B1 of the second apartment type, which is occupied by the worktable composed of the corresponding first paper universal component c 4A3 and the second paper universal component c 4B3. The first recessed area of the second unit

Embodiment 3

[0130] The third temporary small building type:

[0131] 1. A temporary small building assembled from paper general components, the difference from Embodiment 1 and Embodiment 2 is:

[0132] Such as image 3 , 4 , 17 and 18, the second groove 7B and the third groove 7C area of the first unit structure 5A of the apartment type, the first groove 7A area of the second unit structure, the second groove 7B of the third unit structure And the third groove 7C area is the third apartment-type traffic area 9C, which is composed of a corresponding first paper general component a 4A1, two second paper general components a 4B1, and two third paper general components a 4C1 The floor of the traffic area 9C of the third apartment type; the first groove 7A area of the first unit structure 5A is the first workshop 10C1 of the third apartment type, which is occupied by the corresponding first paper universal component c 4A3; The area of the first groove 7A of the three-unit structure 5A

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap