Compact A-axis 360-degree rapid rotary air intake device

A rotary air intake, compact technology, used in transmission parts, chemical instruments and methods, belts/chains/gears, etc., can solve the problems of occupying space, not compact enough, etc. Ease of service and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

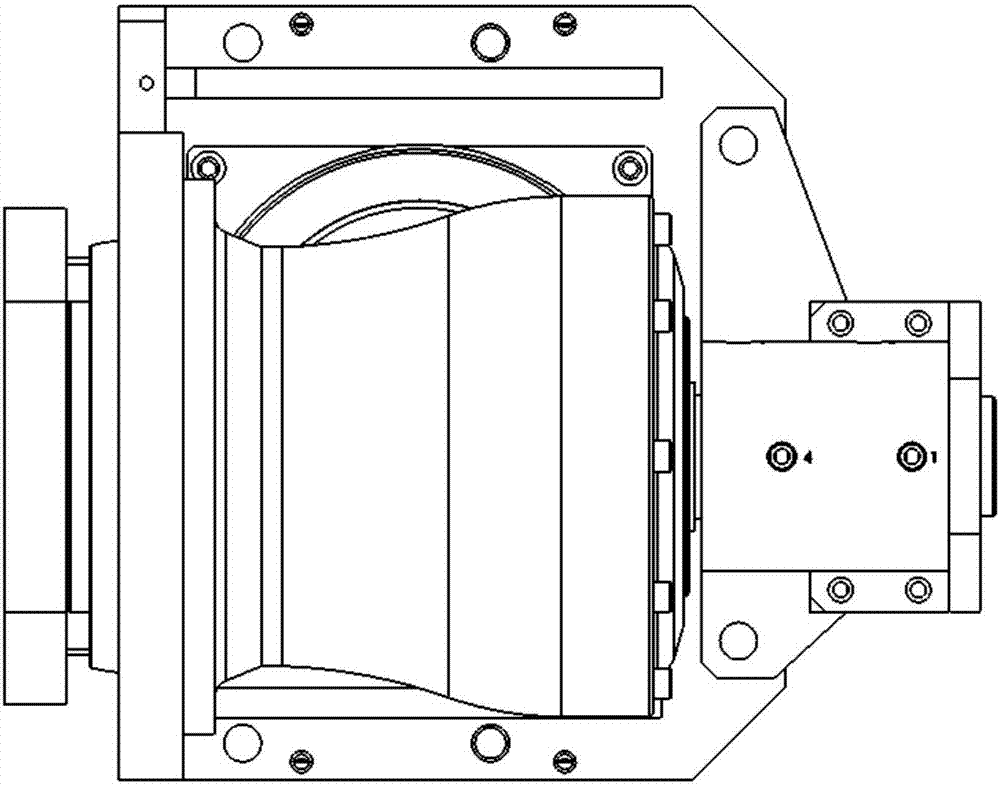

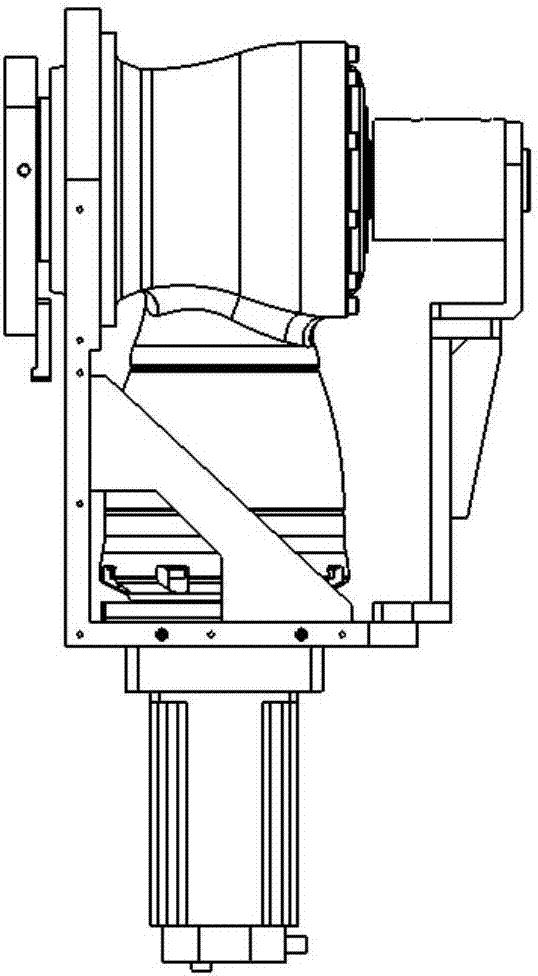

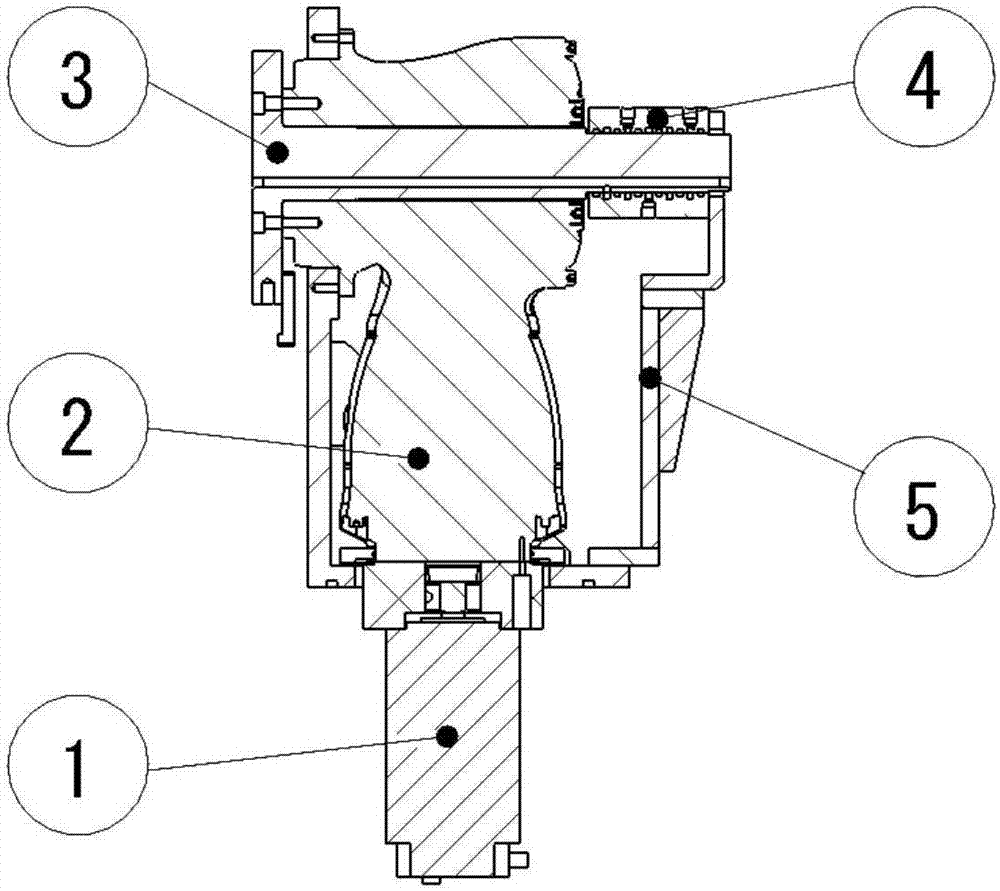

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention will be further described, and this rotatable air intake shaft and principle for high-pressure cleaning machine are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0015] In this embodiment, the compact A-axis 360° quick rotation air intake device has a structure including an A-axis quick rotation device and an air intake device. The A-axis fast rotation device is provided with a motor 1 and a right-angle gear reducer 2 . The compact A-axis 360° rapid rotation air intake device can simultaneously provide stable air intake from the equipment to the fixture when the A-axis rotates rapidly.

[0016] The bottom of the right-angle gear reducer 2 is fixedly installed on the reducer base 5, and the output flange is connected to the flange of the rotating shaft 3; th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap