Parallel straw-burying anti-skid wheel for paddy field

An anti-skid wheel and parallel type technology is applied in the field of parallel paddy field burying grass anti-skid wheels, which can solve the problem that the anti-skid wheel is not suitable for the requirements of front-type wide-width rotary tiller for burying grass in paddy fields. weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

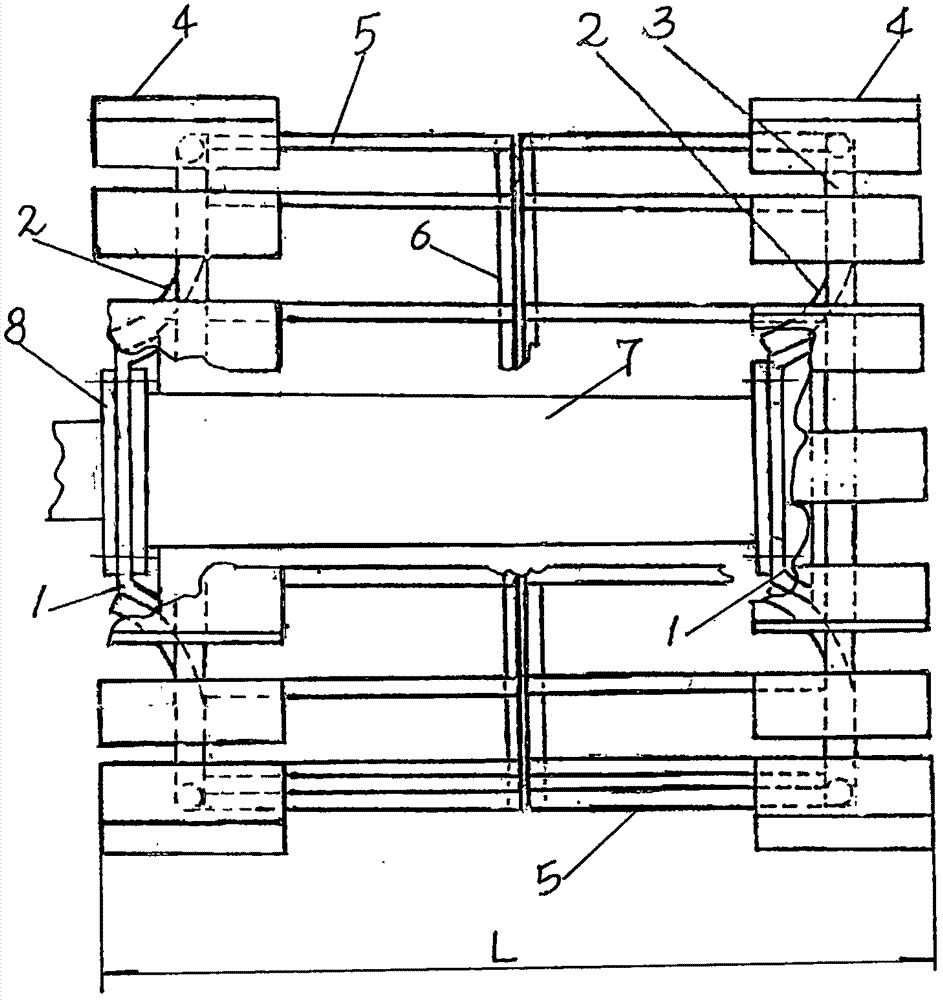

[0009] Such as figure 1 The shown parallel anti-skid wheel for paddy field grass burying includes flange 1, support rib 2, rim 3, anti-skid gear 4, grass pressing strip 5, lining ring 6, and wheel hub 7. By adding wheel hub 7. Two anti-skid wheels are connected in parallel. The width L of the anti-skid wheel for paddy field burying grass after parallel connection is 600-800 millimeters, and the diameter is 760-880 millimeters. Steel is made, and anti-slip tooth 4 is made of angle steel, and grass-pressing strip 5 is made of flat iron, and during operation walking, anti-slip tooth 4 walks on floor soil, and grass-pressing strip 5 intensity is little, and its circumference diameter is less than anti-slip tooth 4 circumference diameters, and grass is pressed Strip 5 does not go through the floor soil. When in use, the anti-skid wheel for burying grass in the parallel paddy field is fixed with the wheel hub 8 of the hand trailer. Semi-suspended in the floating soil to bury the grass

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap