Novel damping suspension

A new type of suspension technology, applied in the direction of power plant, jet propulsion device, internal combustion propulsion device, etc., can solve the problems of process and simulation error, consume a lot of manpower, material resources, time, vibration, etc., to avoid resonance and solve vibration noise Problems, Effects of Simple Structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

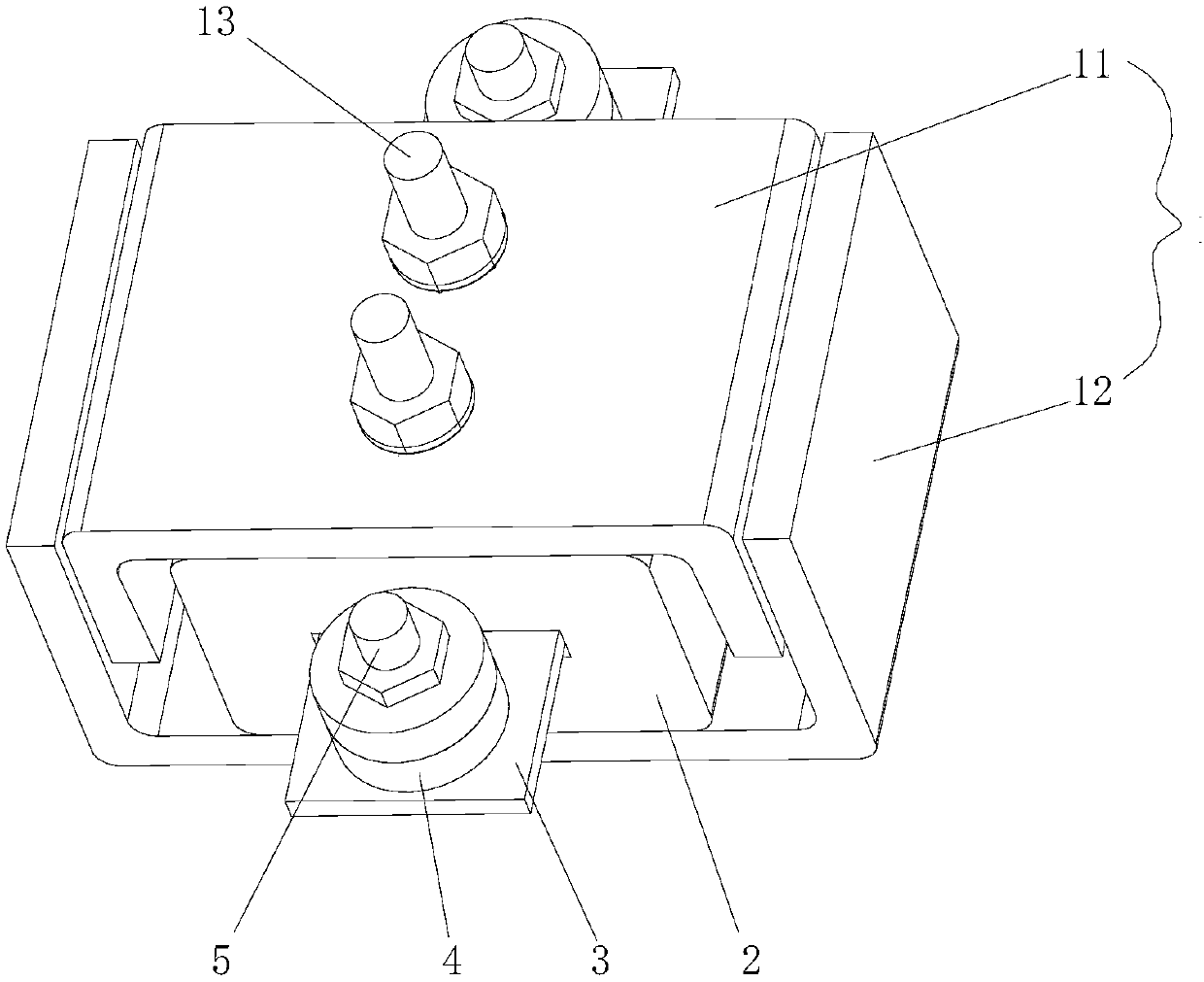

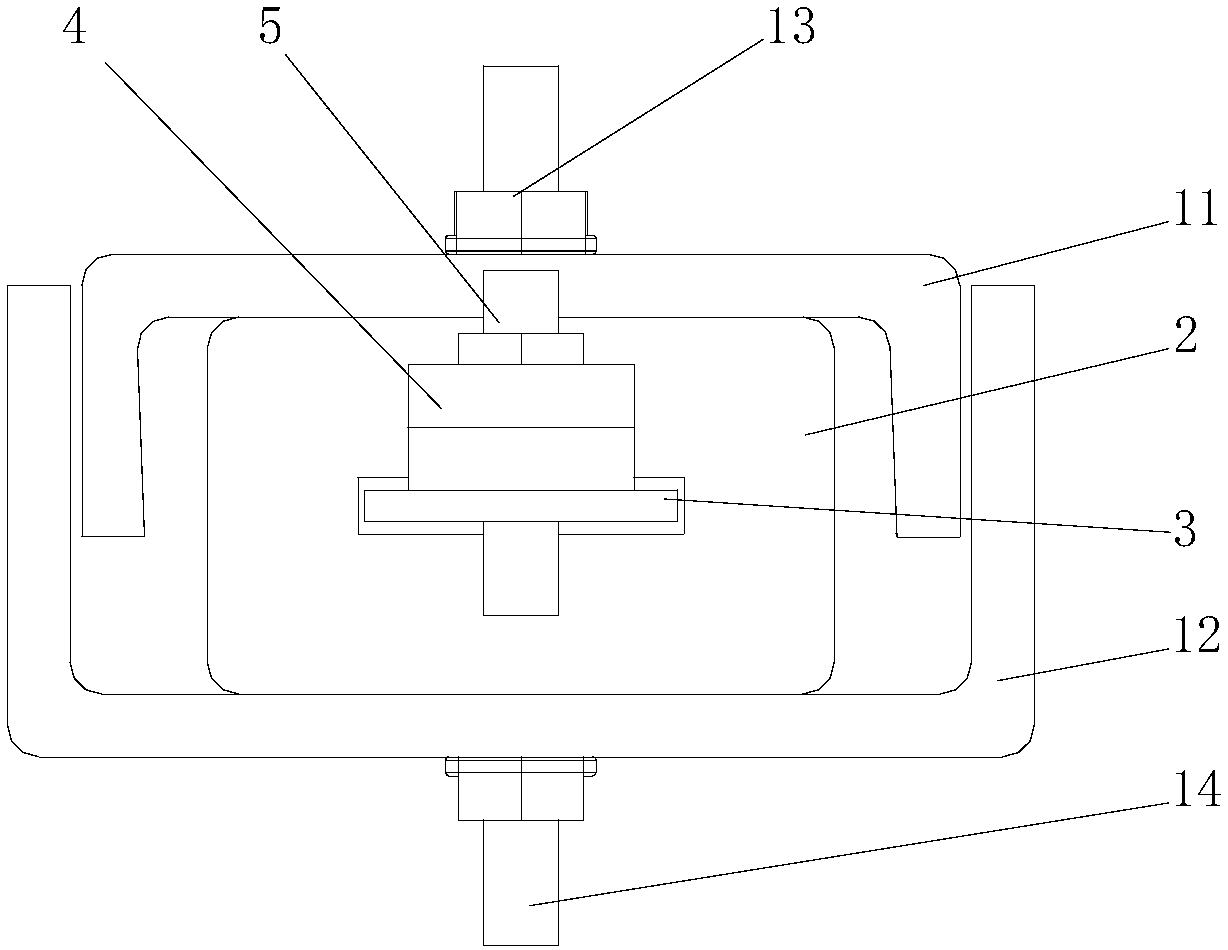

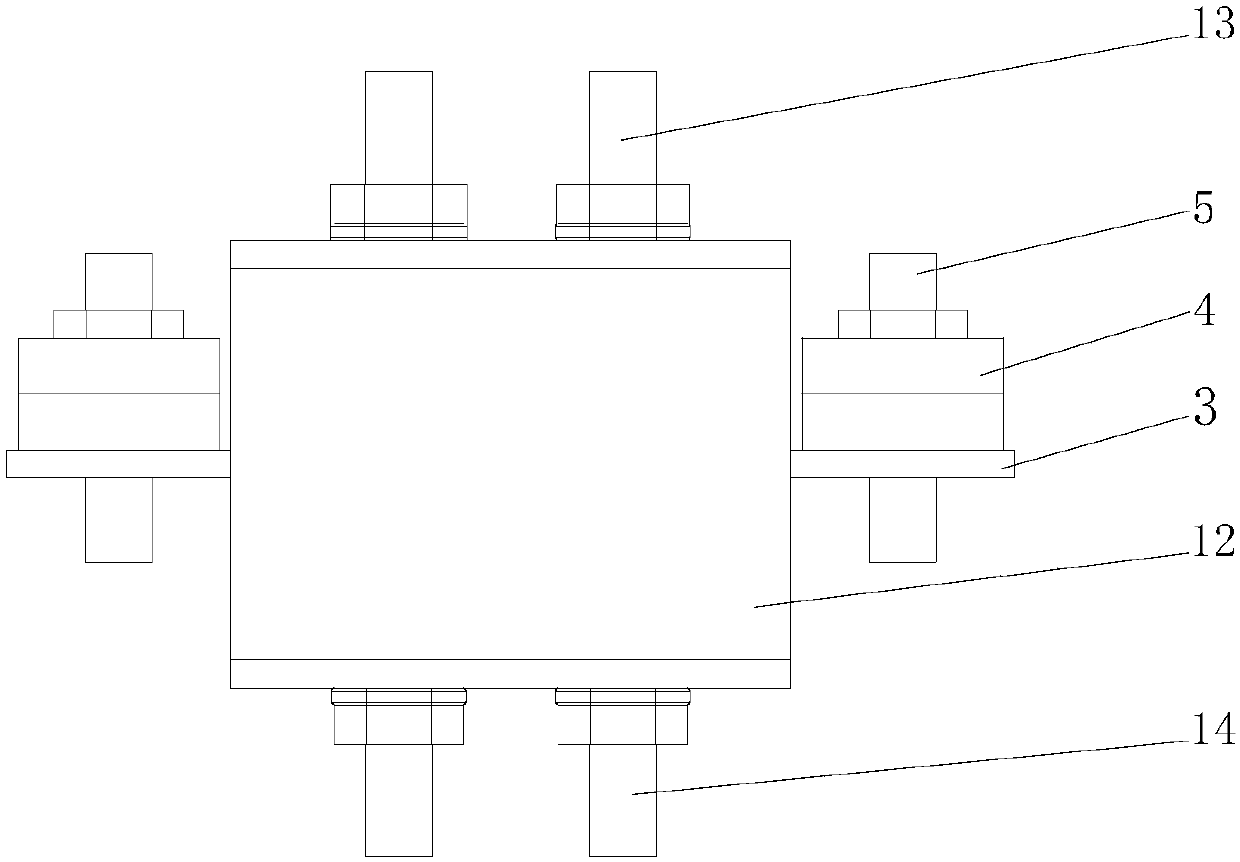

[0022] The novel damping mount of the present invention is arranged between the automobile engine and the automobile chassis, such as Figure 1~Figure 3 As shown, the vibration damping suspension includes a shell 1 , a rubber part 2 , a metal plate 3 and a mass block 4 .

[0023] The casing 1 includes an upper casing 11 and a lower casing 12, and the rubber part 2 is arranged between the upper casing 11 and the lower casing 12. In this embodiment, the upper casing 11 has a U-shaped structure with the opening facing downward, and the lower The casing 12 has a U-shaped structure with an opening facing upwards, and the two sides of the U-shaped structure of the lower casing 12 are located outside the two sides of the U-shaped structure of the upper casing 11 . On the upper housing 11, a first bolt 13 is fixed, and the first bolt 13 is used to conne

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap