High-pressure rotary joint

A rotary joint, high-pressure technology, applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., can solve problems such as oil leakage, rotary joints cannot be effectively sealed, and affect work, etc., to achieve good sealing effect and simple structure , Stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

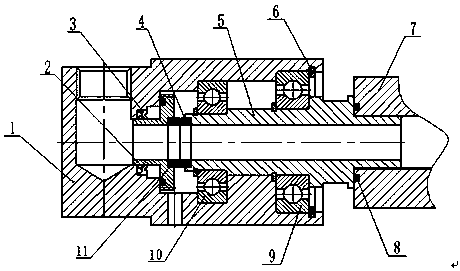

[0012] Examples, see attached figure 1 , a high-pressure rotary joint, characterized in that it includes a housing 1, a mounting seat 2, a left sealing ring 3, a moving ring 4, a rotating shaft 5, a retaining ring 6 for a hole, a bracket 7, a right sealing ring 8, a right rolling bearing 9, The left rolling bearing 10 and the static ring 11, the right end of the housing 1 in the horizontal direction is processed with a stepped hole, the vertical direction is processed with a cylindrical hole and the two holes are connected, the left end surface of the mounting seat 2 is processed with a groove, the mounting seat 2 is fixedly installed on the end face of the inner hole at the right end of the casing 1, the left sealing ring 3 is installed at the left end of the mounting seat 2, the moving ring 4 is fixedly installed in the groove at the left end of the rotating shaft 5 and closely fits with the static ring 11, so The outer ring of the left rolling bearing 10 is installed in the in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap