Oilfield well testing vehicle electric drive system

A technology of well testing and vehicle electricity, which is applied in general control systems, control/regulation systems, wellbore/well components, etc., can solve problems such as low control accuracy, high labor intensity of workers, and inability to meet the requirements of modern oilfield production. Low useless energy consumption and high energy conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016] The present invention will be further explained below in conjunction with the drawings:

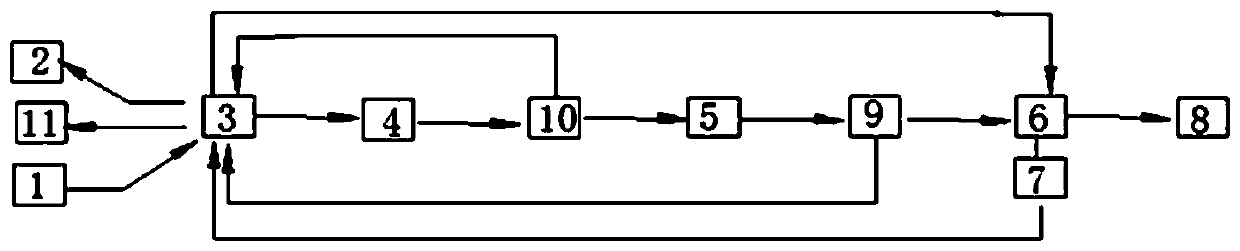

[0017] As shown in the figure, an oil field test vehicle electric drive system includes a console. The console is equipped with a control component 1 and a liquid crystal display 2. It is characterized by a PLC controller 3, a generator 4, a rectifier unit 5. The vector inverter 6, the winch motor 8, the vector inverter 6 is equipped with a Hall torque sensor 7, the power output terminal of the generator 4 is connected to the input terminal of the rectifier unit 5, and the output terminal of the rectifier unit 5 is rectified and its output terminal is input to the vector inverter 6 The input terminal of the vector inverter 6 is connected with the winch motor 8 to drive the winch motor. There is an undervoltage protector 9 between the rectifier unit 5 and the vector inverter 7, and between the generator 4 and the rectifier unit 5. The leakage protector 10 and the electric drive system are

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap