Pull rod linkage mechanism

A linkage mechanism and tie rod technology, applied in mechanical equipment, transmission, belt/chain/gear, etc., can solve the problem of increased error of auxiliary parts, and achieve the effect of improving service life and simple overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

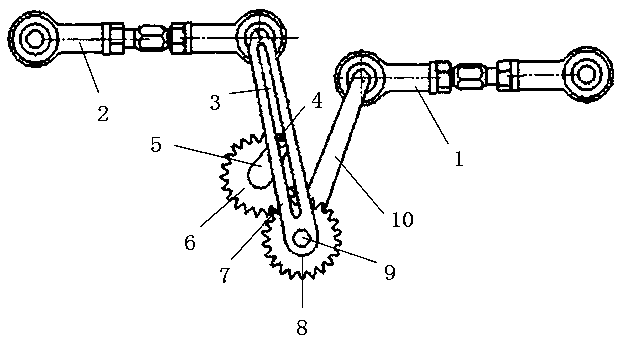

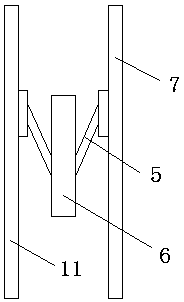

[0018] Such as figure 1 and 2 As shown, a pull rod linkage mechanism includes an active rod 1 and a driven rod 2, the active rod 1 is connected with the first gear 8 through the connecting rod 10, and the first gear 8 is hinged on the frame, namely figure 1 The position of the middle hinge point 9, the first gear 8 is meshed with the second gear 6, the first rocker 7 is arranged between one side of the driven lever 2 and one side of the first gear 8 and the driven A second rocker 11 is arranged between the other side of the rod 2 and the other side of the first gear 8 .

[0019] The first rocker 7 and the second rocker 11 are arranged parallel to e

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap