Adjustable material stirring device

A material arm and shaft technology, applied in the field of adjustable material shifting device, can solve the problems of high cost, complex structure of the material blocking device, troublesome installation, etc., and achieve the effect of convenient operation, simple structure and compact installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

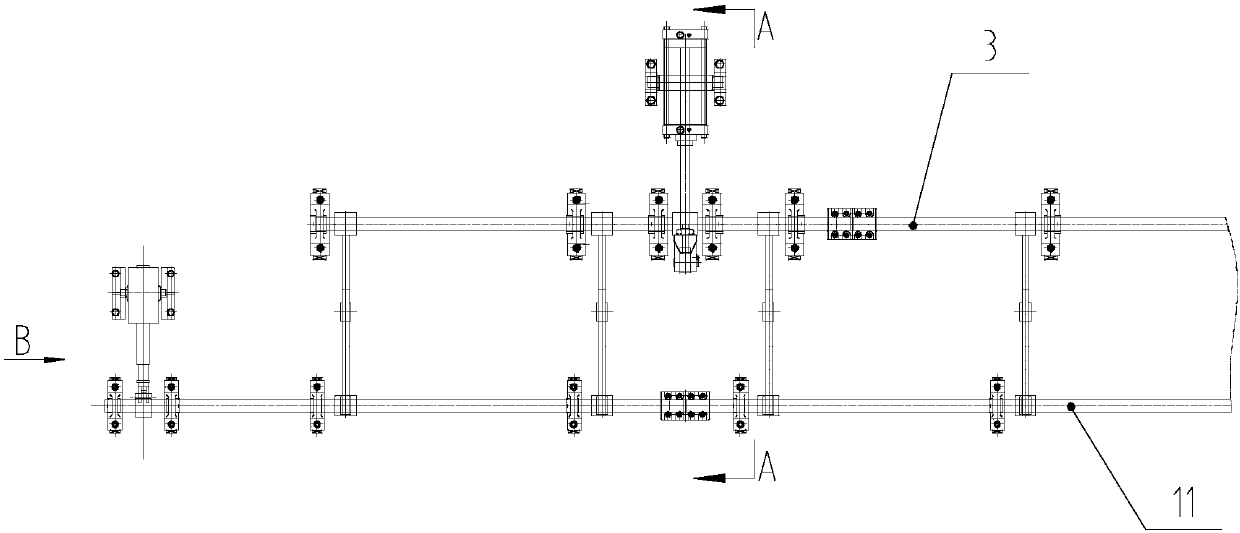

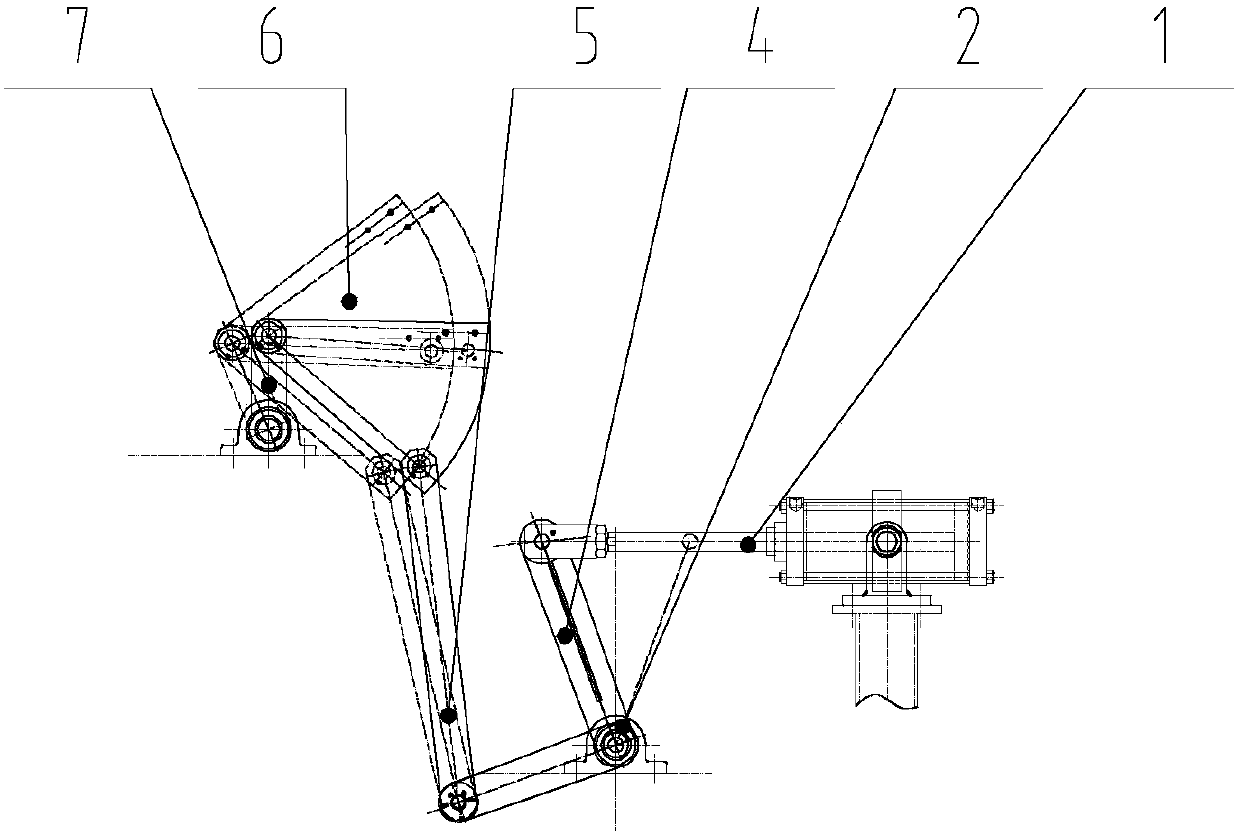

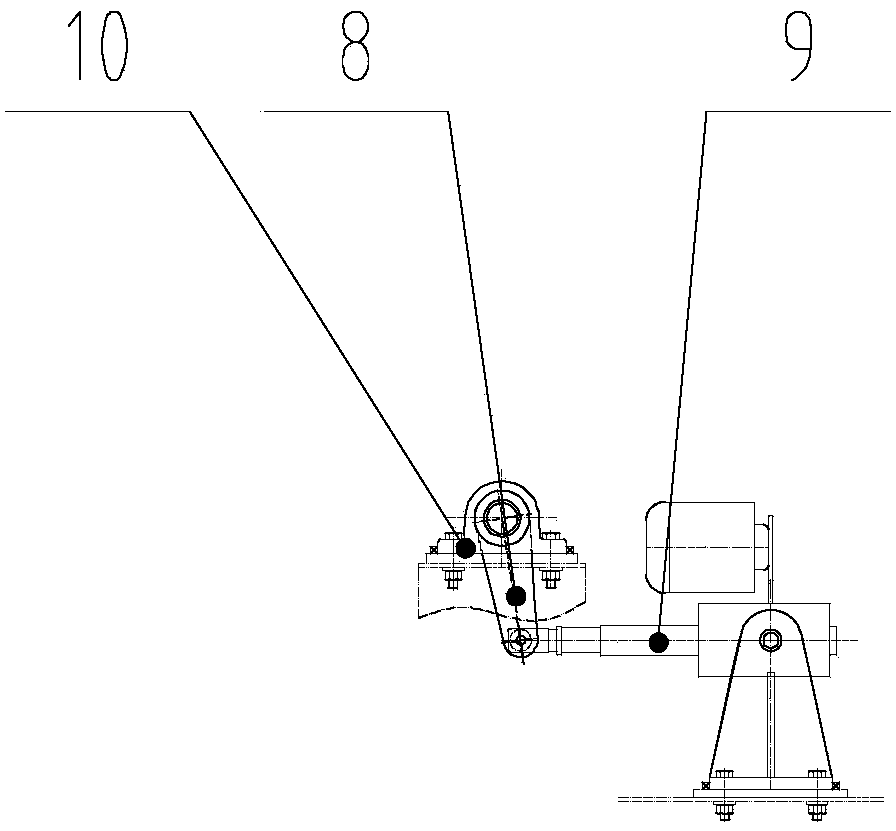

[0012] see Figure 1-Figure 3 , an adjustable material shifting device, characterized in that it includes a frame, a cylinder 1, a first bearing seat 2, a first rotating shaft 3, a single-section swing rod 4, a double-section swing rod 5, a material-setting arm 6, and an adjustment swing arm 7. Push rod swing arm 8, electric push rod 9, second bearing seat 10 and second rotating shaft 11.

[0013] The first bearing seat 2 is installed on the frame, and the first rotating shaft 3 is installed on the first bearing seat 2 .

[0014] The cylinder 1 includes a cylinder body and a telescopic piston rod, the cylinder body 1 is mounted on the frame through a first pin shaft, the axis of the first pin shaft is parallel to the first rotating shaft 3, and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap