Improved type coal economizer

An economizer and an improved technology, applied in the directions of feed water heaters, preheating, steam generation, etc., can solve the problems of not too large air extraction, safety accidents, etc., and achieve simple structure, energy saving, and high heat exchange rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

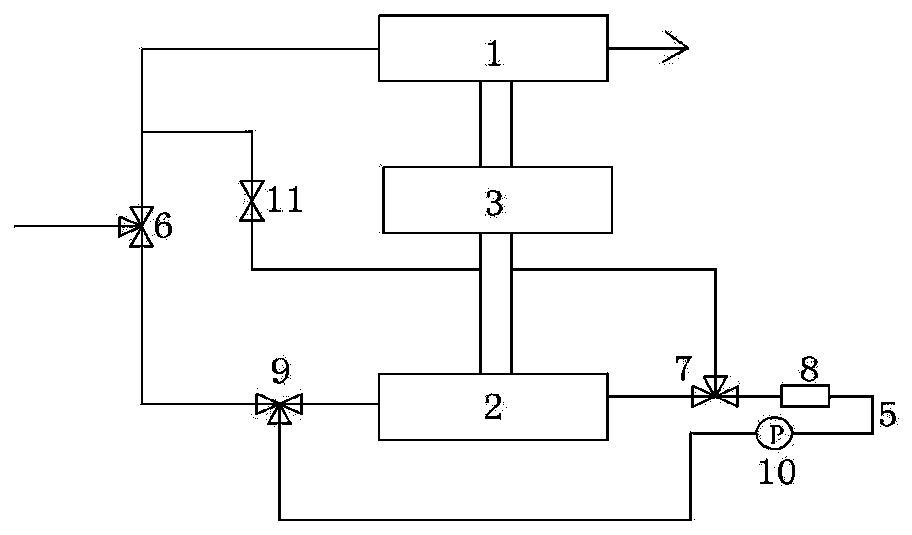

[0014] An improved economizer according to the present invention includes an economizer body, a denitrification device 3 and a circulation pipe 5. The economizer is decomposed into an upper part 1 of the economizer and a lower part 2 of the economizer, wherein the upper part 1 of the economizer, the lower part 2 of the economizer The denitrification device 3 and the lower part of the economizer 2 are installed in sequence, and both are arranged in the flue. The input end of the upper part 1 of the economizer and the input end of the lower part 2 of the economizer are both connected to the same water supply pipe 4, and the output of the lower part 2 of the economizer The end is connected to the input end of the circulation pipe 5, and the output end of the circulation pipe 5 is connected to the input end of the lower part 2 of the economizer. The input end of the upper part 1 of the economizer and the input end of the lower part 2 of the economizer are connected to the water supply

Embodiment 2

[0017] This embodiment is an improvement made on the basis of Embodiment 1. In this embodiment, the output end of the lower part 2 of the economizer and the input end of the upper part 1 of the economizer are connected to each other through a bypass. Bypass valve 11. When heat exchange is not required, adjust the tee A6, connect the end of the water supply pipe 4 connected to the lower part of the economizer 2, close the end of the water supply pipe 4 connected to the upper part of the economizer 1, adjust the tee B9, and open the tee A6 The end connected to the lower part of the economizer 2, close the return water end of the circulation pipe 5, adjust the tee C7, open the end of the lower part of the economizer 2 connected to the bypass, and close the end of the lower part of the economizer 2 connected to the circulation pipe 5 In this embodiment, the outlet water from the lower part 2 of the economizer is connected to the input end of the upper part 1 of the economizer through

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap