Method for measuring content of calcium in anthracite

A technology of anthracite, calcium content, applied in the field of chemical industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

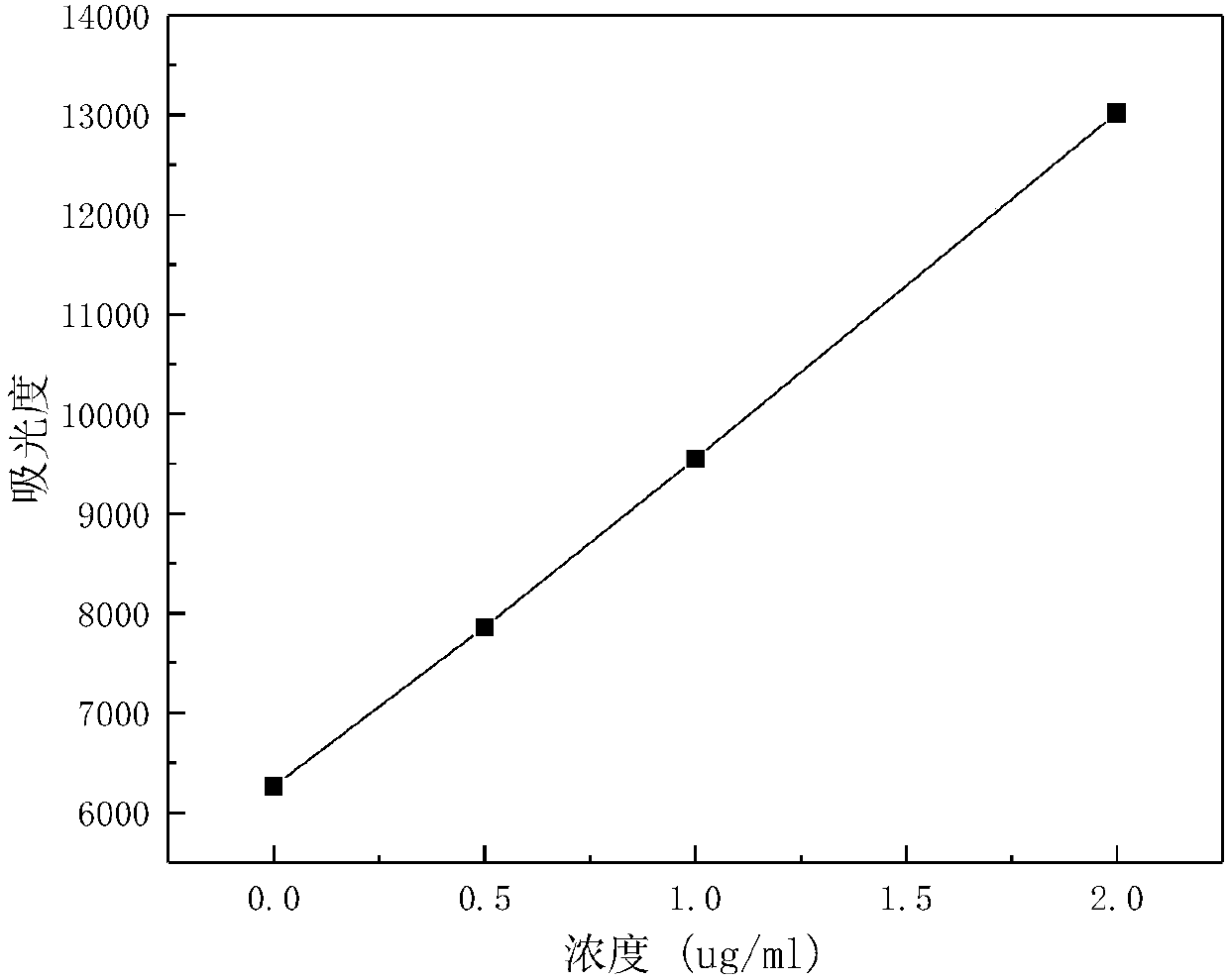

Image

Examples

Embodiment 1

[0049] (1) Take the anthracite sample 1 to be tested, the anthracite sample 2 to be tested, the anthracite sample 3 to be tested and the anthracite sample 4 to be tested and pulverize completely respectively, and pass through a 200-mesh sieve respectively to obtain anthracite powder 1, anthracite powder 2, and anthracite powder 3 and anthracite powder 4; weigh 0.1 g of anthracite powder 1 in a platinum crucible, and add 0.9 g of anhydrous sodium carbonate and 0.3 g of sodium tetraborate and mix; place the platinum crucible in a muffle furnace and keep it warm at 890-920 degrees Celsius 15 minutes; use 30mL of boiling hydrochloric acid with a mass concentration of 20% to transfer the molten product to a polytetrafluoroethylene beaker for leaching treatment, and clean the platinum crucible to obtain the leaching solution, place the leaching solution for ventilation until it is clear, and then transfer to a 100mL capacity In the bottle, dilute to the volume with ultrapure water to ob

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap