Automatic feeding device for discontinuous blanks

An automatic feeding, intermittent technology, used in the direction of conveyor objects, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

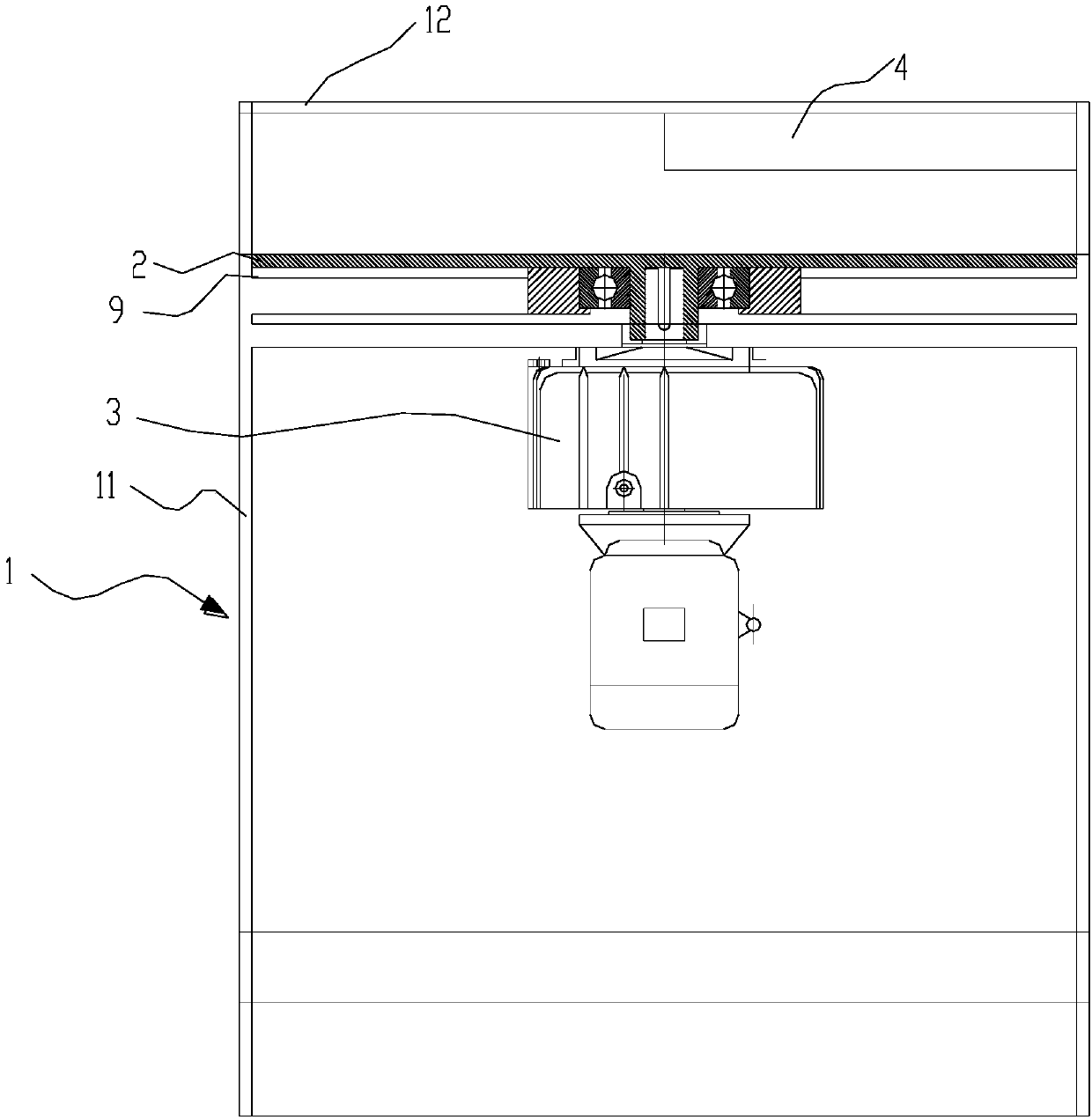

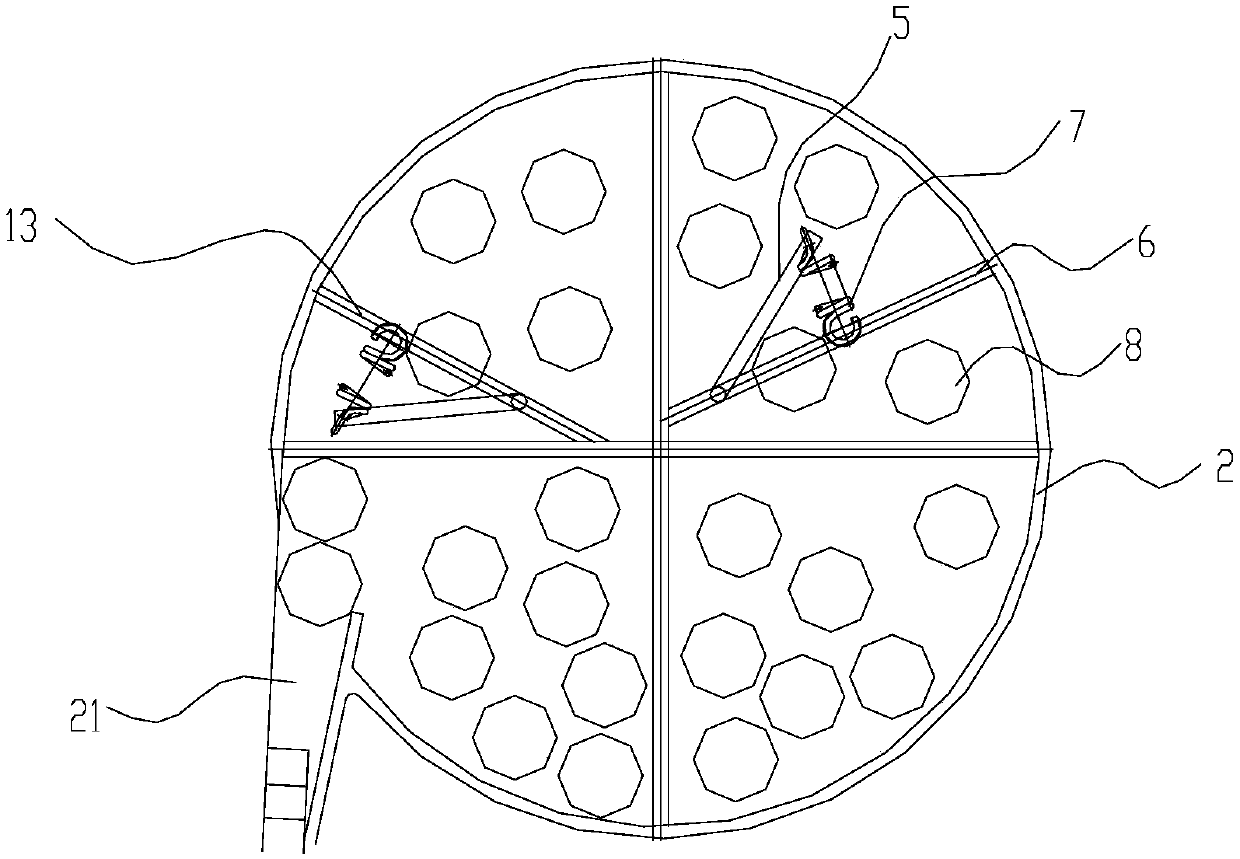

[0021] Such as figure 1 with figure 2 As shown, the present invention provides an automatic feeding device for intermittent blanks, which includes a frame 1 , a rotating disk 2 and a reducer 3 . The rotating disk 2 is used to hold the intermittent billet 8 , and the rotating disk 2 is provided with a discharge port 21 . The feeding method can be directly fed from above. The rotating disk 2 and the fixed baffle 4 are fixed on the frame 1. The frame 1 specifically includes four vertical bars 11 and four horizontal bars 12, and the four horizontal bars 12 are sequentially connected end to end to form a ring bar, and the ring bars are fixed At the top of

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap