Tree digging machine

A tree digging machine and tree claw technology, applied in the field of tree digging machines, can solve the problems of low efficiency of manual tree digging, low survival rate of trees, etc., and achieve the effect of vigorously promoting the use, improving labor efficiency, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

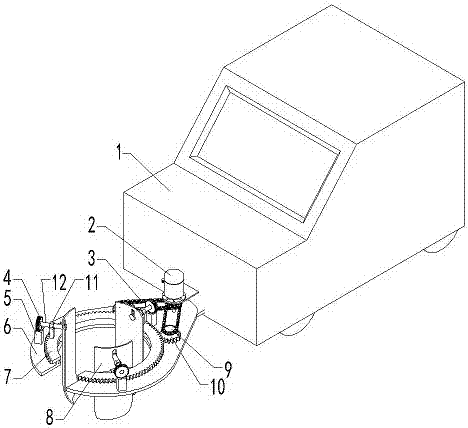

[0025] Examples such as figure 1 , figure 2 As shown, a tree digging machine includes a loader 1, the front end of the loader 1 is provided with a tree digging device, and the tree digging device includes a tree claw device for cutting off tree roots to form a package and a tree claw device for driving The driving device drives the tree claw device to rotate and tighten to form a soil package for fixing tree roots.

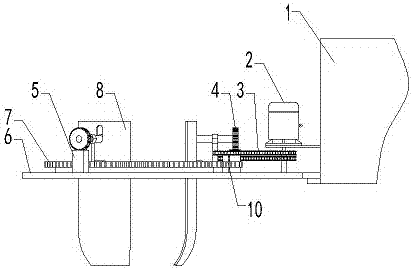

[0026] The tree digging device includes a fixed seat 6 with an opening at the front end, and the rear end of the fixed seat 6 is connected with the loader 1 .

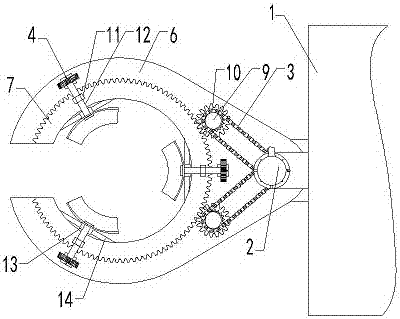

[0027] The fixed seat 6 is a fixed plate with a circular ring guide groove inside, and the fixed seat 6 is rotatably connected with an open ring gear 7 through the guide groove, and the open ring gear 7 can continuously rotate in the guide groove of the fixed seat 6 .

[0028] The split ring gear 7 is an incomplete rotary outer ring gear with an opening. When the opening part of the fixed seat 6 overlaps w

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap