No-air-entrapped copper-boron nitride melt efficient stirring method and device

A stirring method and boron nitride technology, applied in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., can solve the problems of entrainment and low stirring efficiency, and solve the technical problems of entrainment and low stirring efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

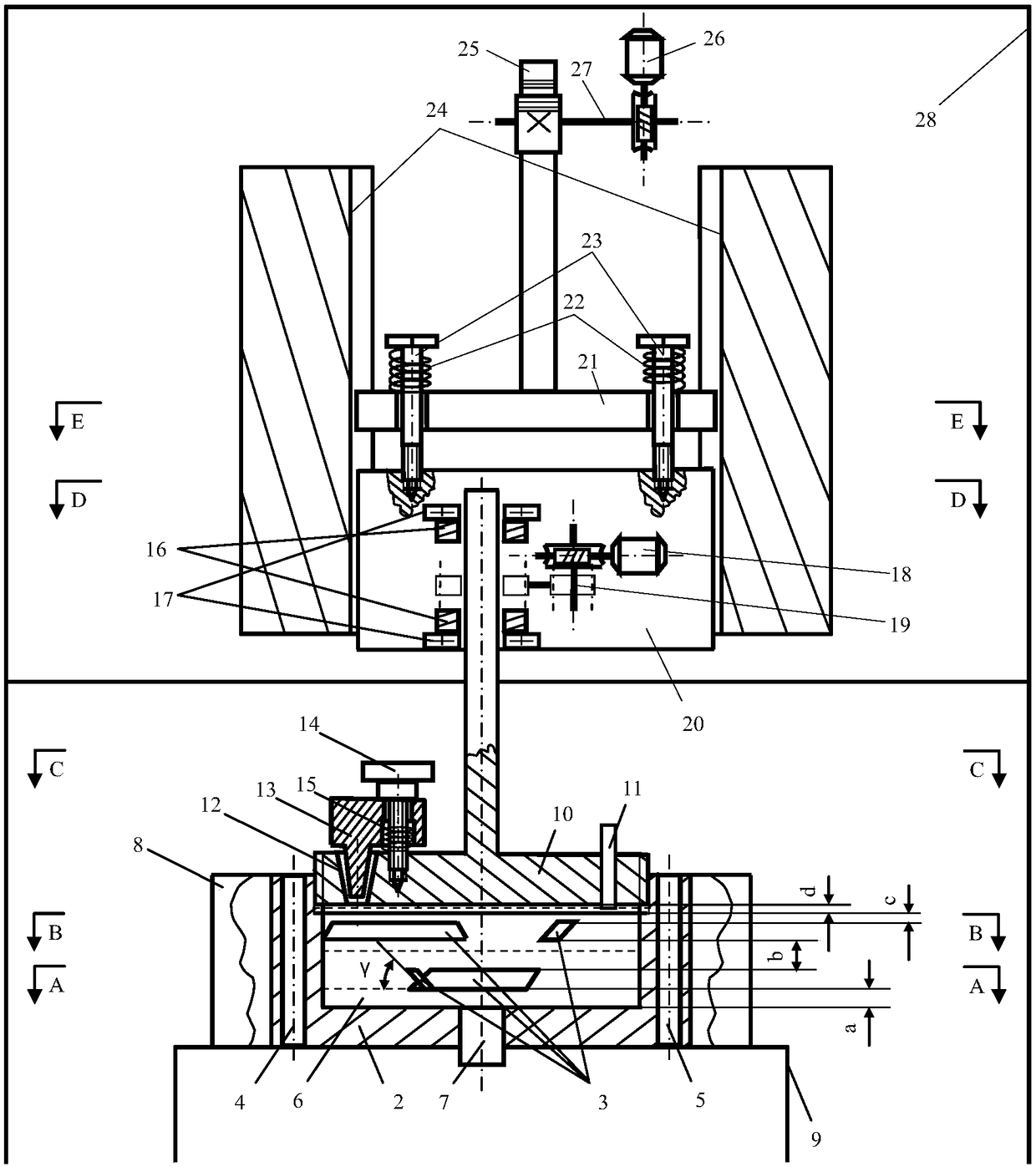

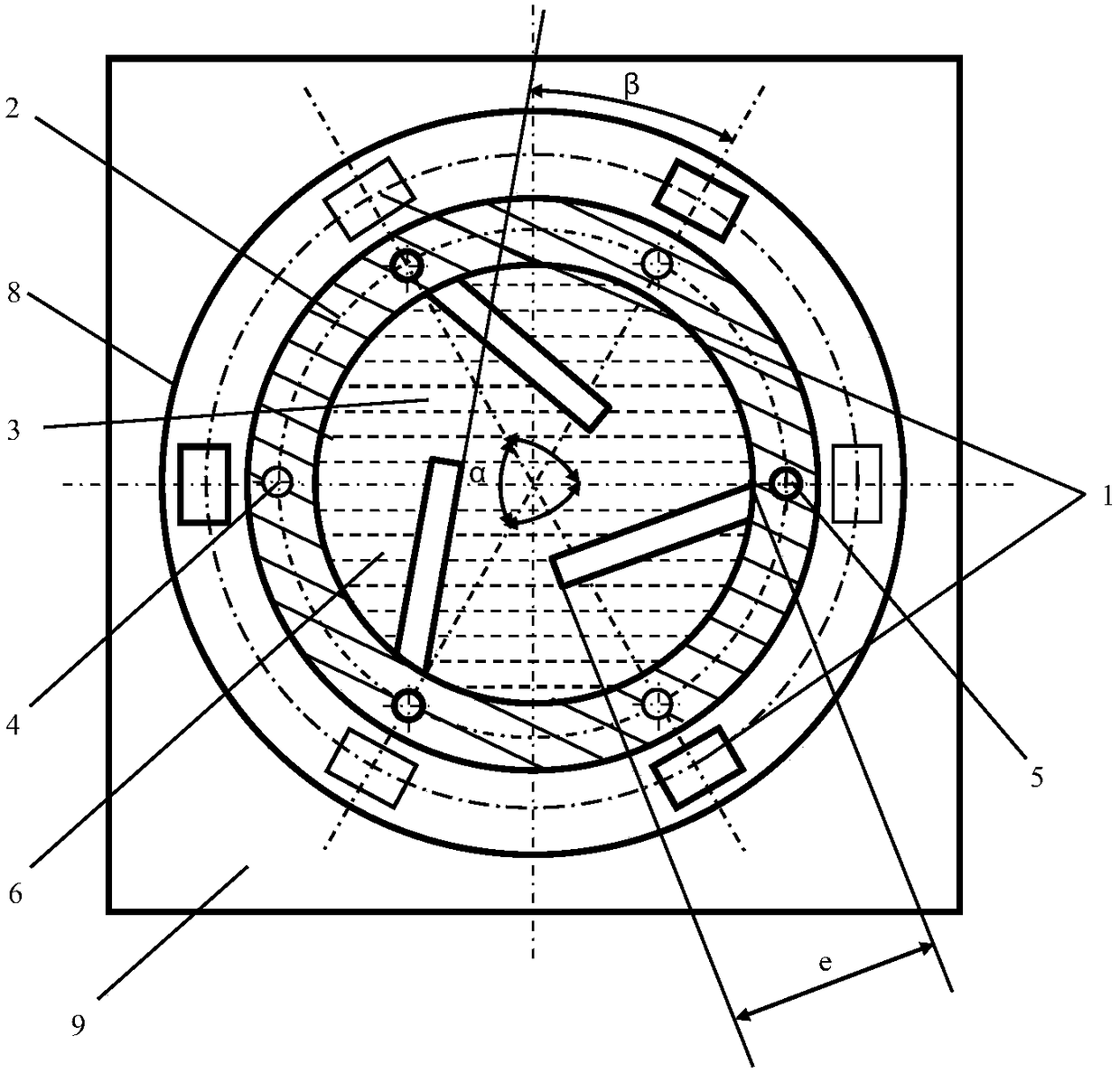

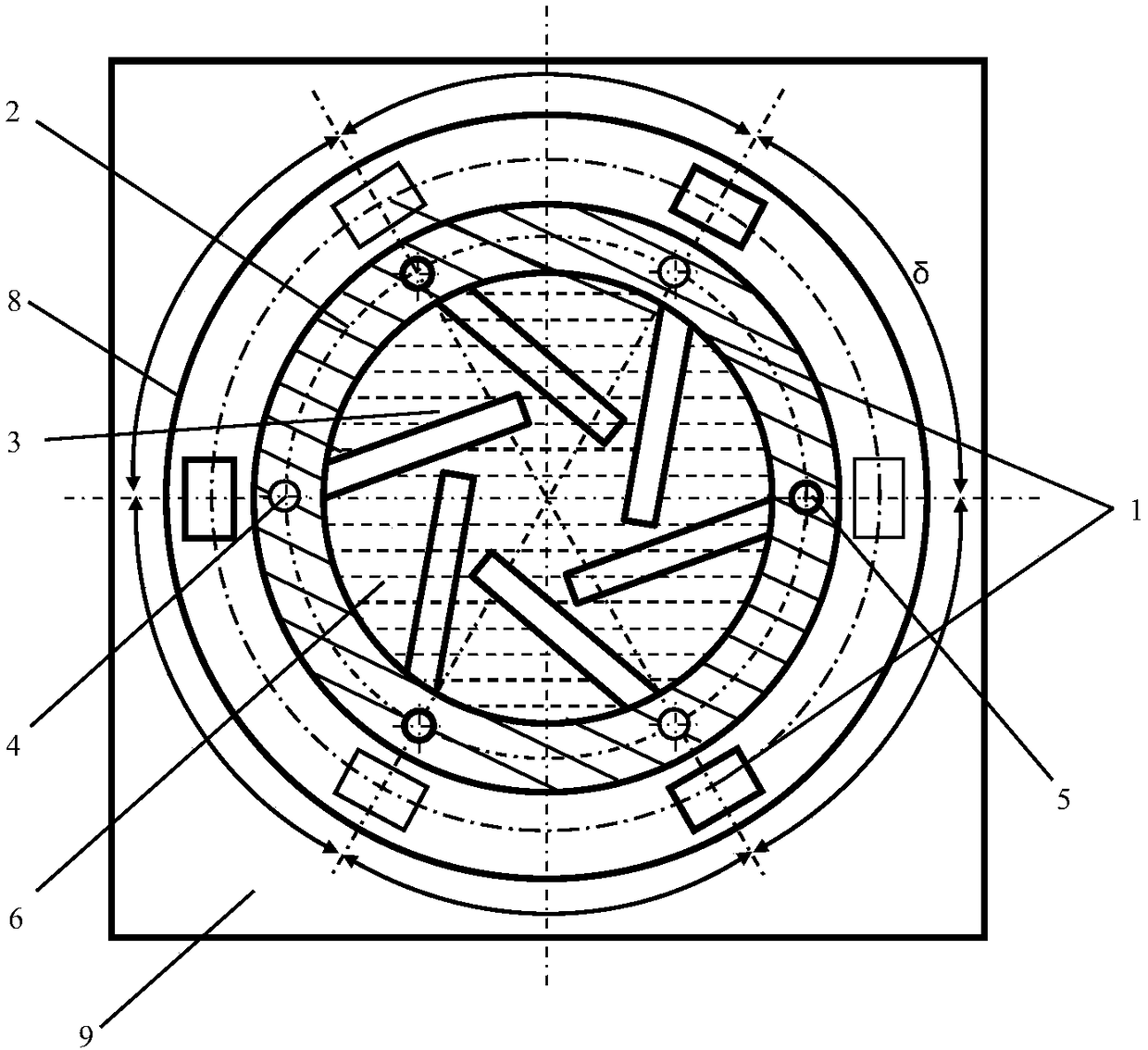

Method used

Image

Examples

Embodiment approach 1

[0030] Embodiment 1, under the condition that the power of the high-speed electromagnetic stirring device is 20kW, the rotating speed is 900 rpm, a is 0mm, b is 0mm, c is 0mm, and d is 5mm, after stirring stably for 1 minute and 50 seconds, you can get Copper-boron nitride melt with no entrained gas and uniform distribution of boron nitride particles6.

Embodiment approach 2

[0031] Embodiment 2, under the condition that the power of the high-speed electromagnetic stirring device is 20kW, the rotating speed is 1200 r / min, a is 20mm, b is 20mm, c is 10mm, and d is 10mm, after 2 minutes of stable stirring, no coil can be obtained Copper-boron nitride melt with uniform distribution of gas and boron nitride particles6.

[0032] It can be seen that under the premise of using variable volume graphite crucible to evacuate and isolate the contact between gas and melt, and then under the condition of high power and high speed electromagnetic stirring, the method of the present invention can efficiently prepare gas-free and evenly distributed boron nitride particles. copper-boron nitride melt.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap