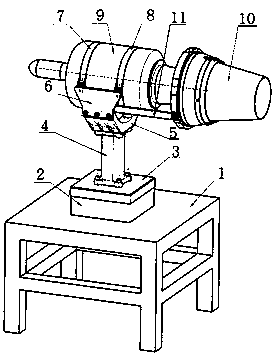

Small-sized turbojet engine thrust vectoring nozzle testing platform

A turbojet engine and vector nozzle technology, which is applied in the aviation field, can solve the problems that small turbojet engines cannot test the force and torque characteristics of the engine vector nozzle, and achieve the effect of simple device structure and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0022] Such as figure 1 As shown, a vector nozzle test bench for a small turbojet engine includes a fixed support, a six-component balance, a support base, a pillar, and a clamping and fixing assembly.

[0023] The fixed support is used to fix the entire test bench, and the fixed support is fixed on the ground.

[0024] The six-component balance is used to test the inherent thrust characteristics of the engine and the force and moment characteristics of the vector nozzle at different rotation angles. The six-component balance is fixedly installed on the support panel of the fixed support by bolts.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap