Laser fluorescence excitation illumination device

A technology for exciting fluorescence and lighting devices, applied in lighting devices, lighting device parts, lighting device cooling/heating devices, etc. Defective, improve heat exchange efficiency, increase the effect of heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The content of the invention will be described below in conjunction with the drawings and embodiments.

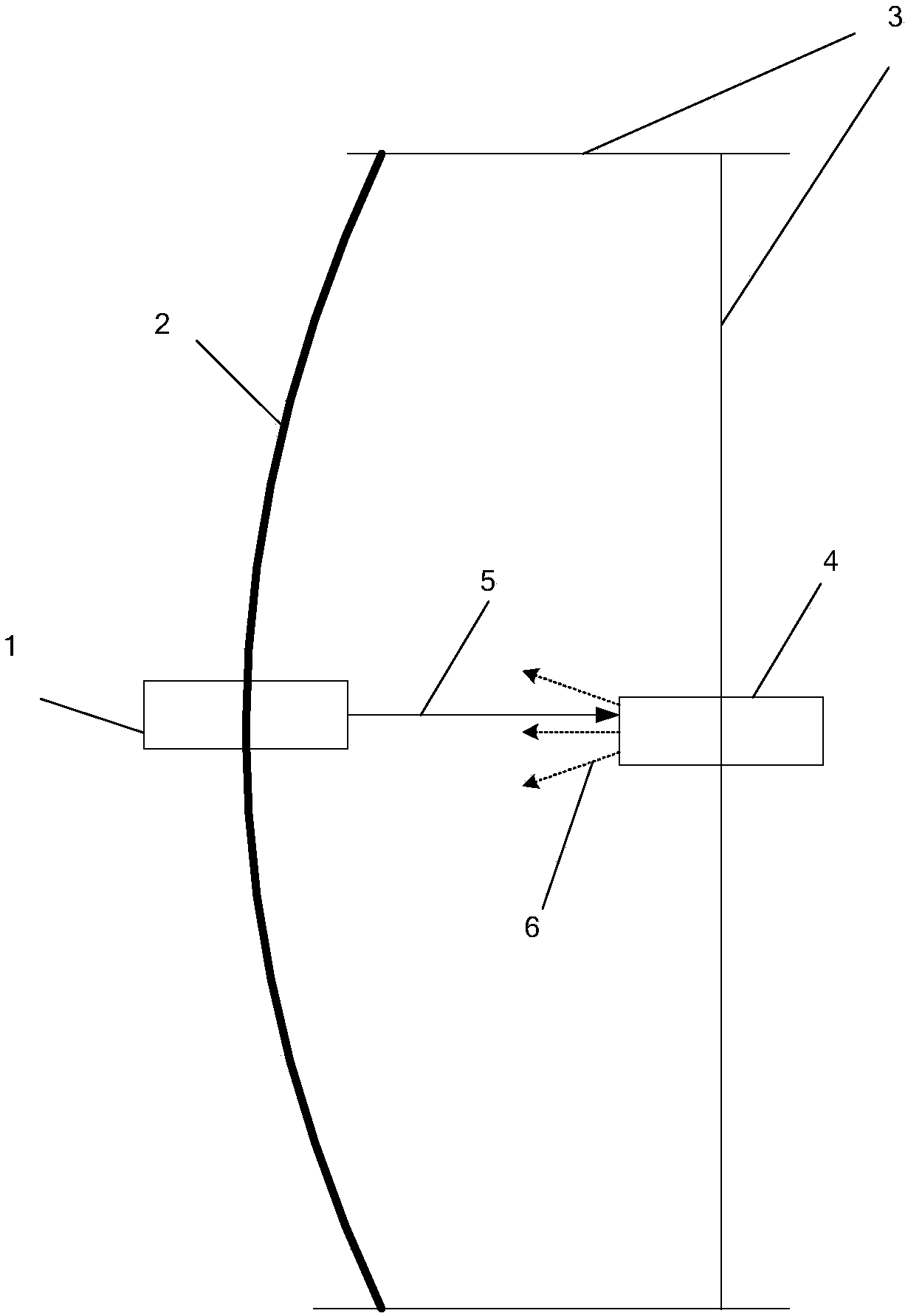

[0022] figure 1 It is a schematic diagram of the lighting device of the present invention, which consists of a laser light source (1), a reflective bowl (2), a support mechanism (3), and a fluorescent excitation device (4), wherein the support structure (3) is used to fix the laser light source (1) , a reflective bowl (2), a fluorescent excitation device (3); the laser light source (1) is located at the bottom of the reflective bowl (2), and projects a laser beam (5) to the fluorescent excitation device (3); the fluorescent excitation device (4) is located in the reflective bowl (2) At the focal point, after receiving the laser beam (5) projected by the laser light source (1), the fluorescence (6) is radiated outward; the fluorescence (6) is figure 1 The dotted line with the arrow in the middle; the radiated fluorescent light (6) reaches the bottom of the reflective bo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap