Smoke-gas treatment system in production and pouring process of submerged arc furnace

A submerged arc furnace and flue gas technology, which is applied in the direction of dispersed particle filtration, building components, and combined devices, can solve the problems of low density, high flue gas temperature, and large specific resistance, and achieve the effect of simple structure and simple cylinder structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

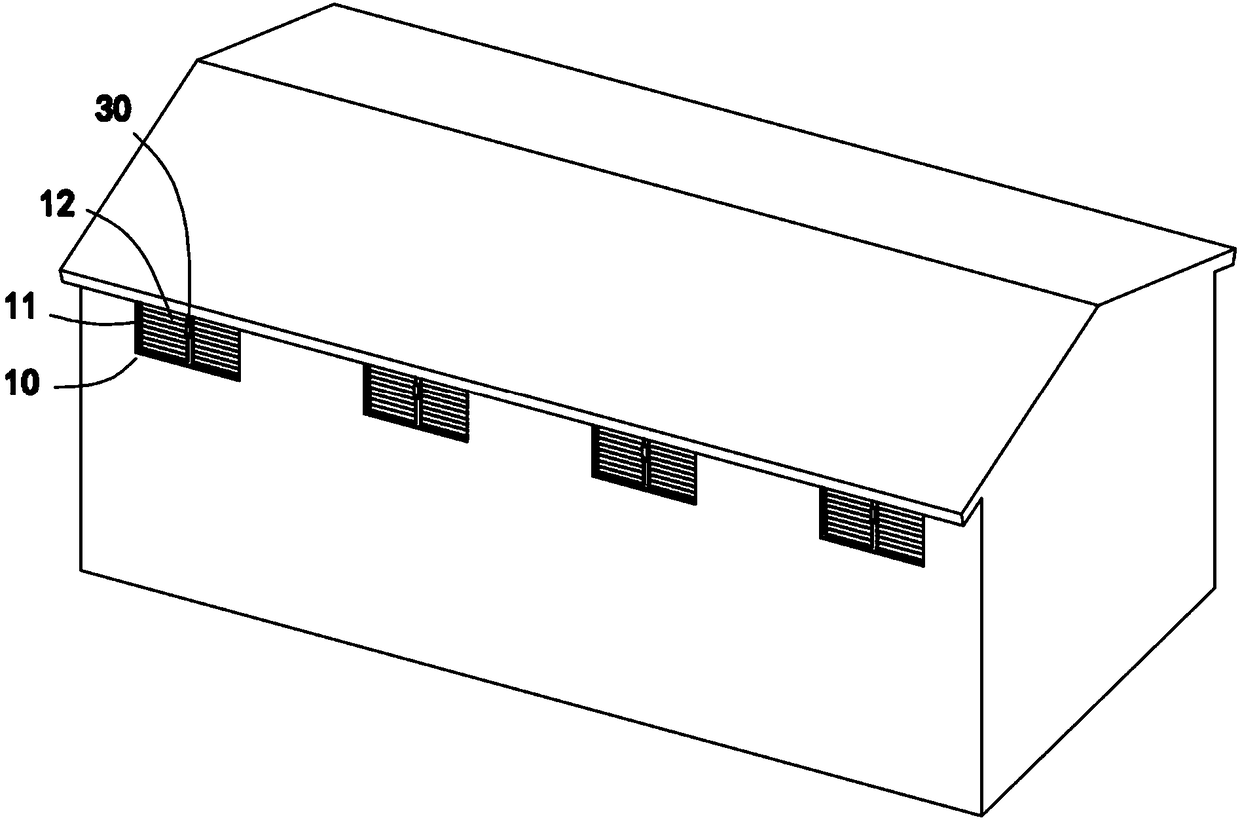

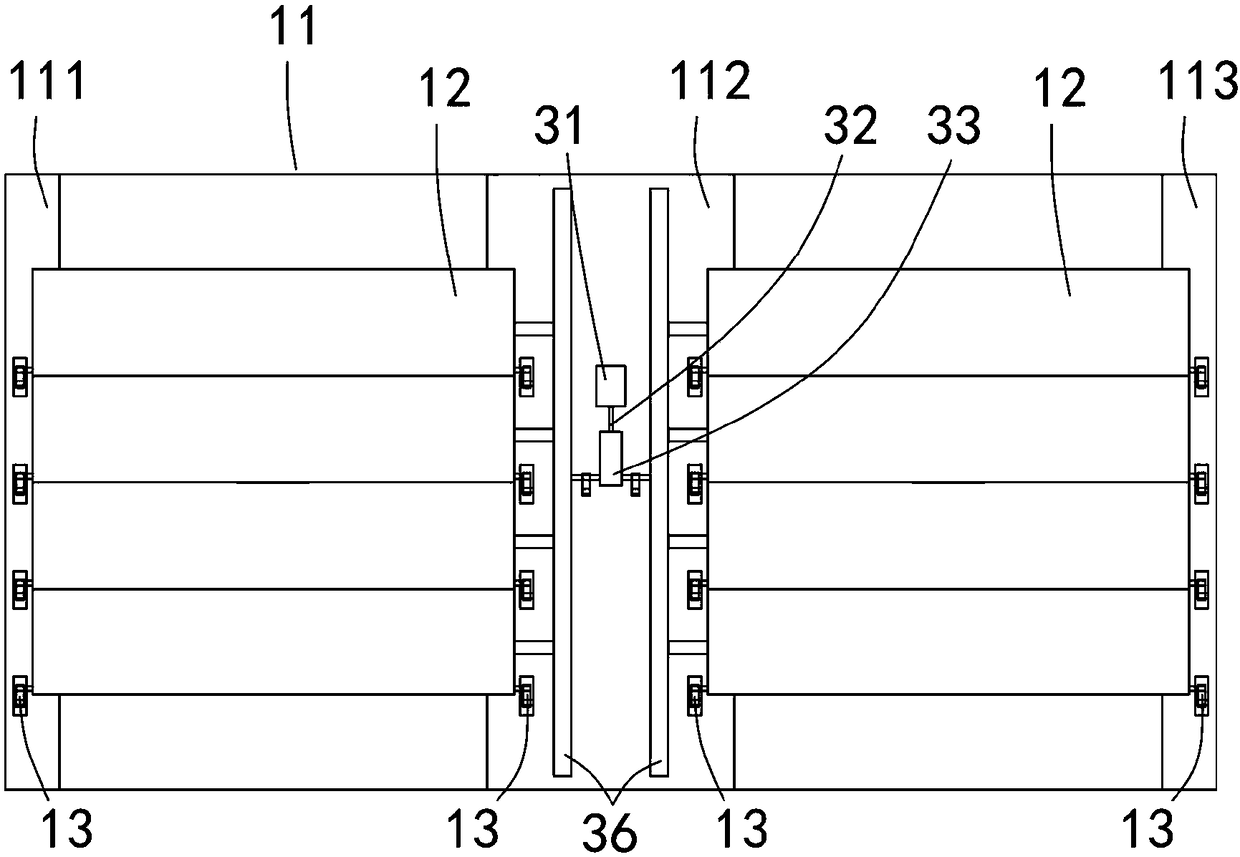

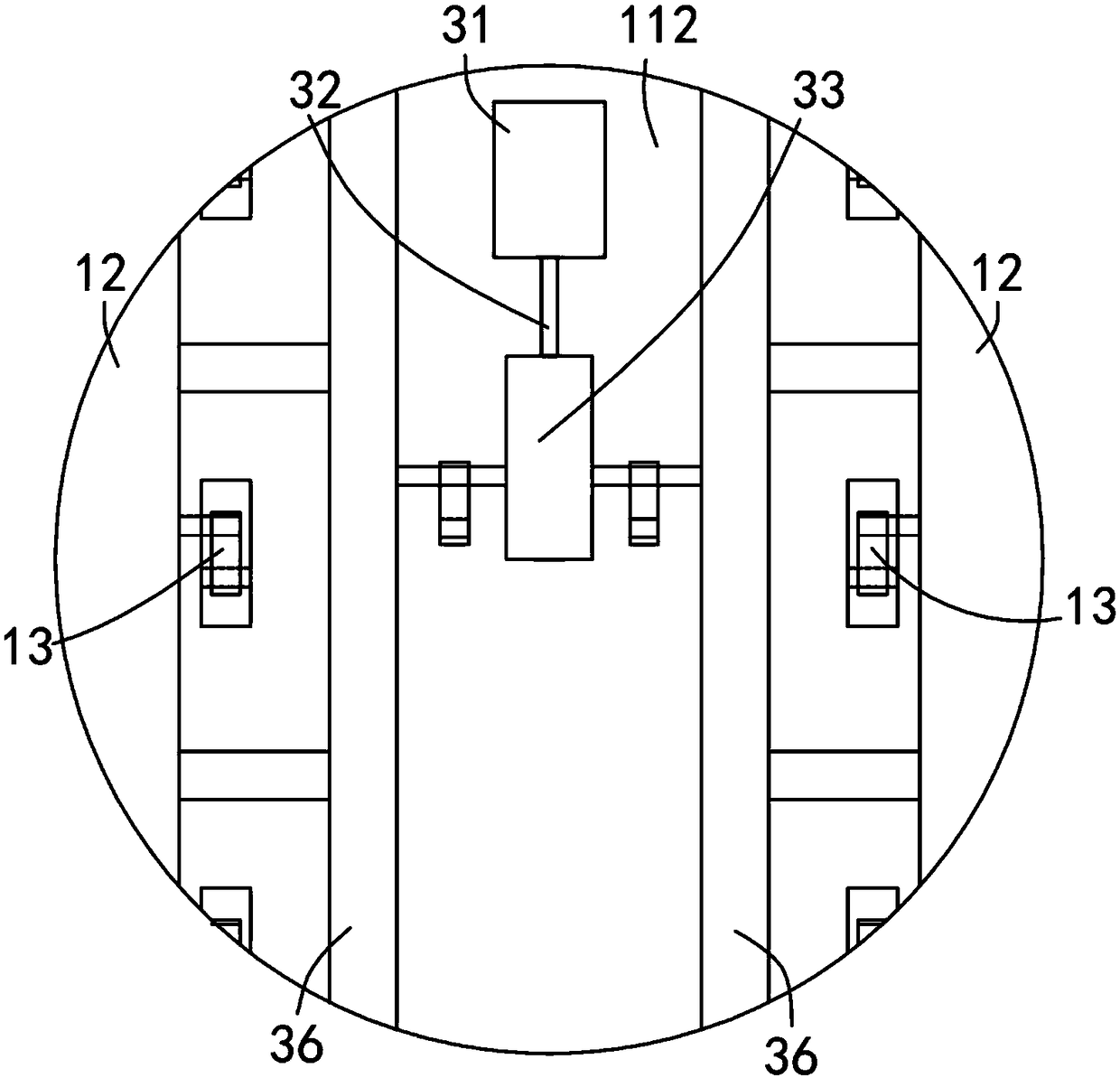

[0026] see Figure 1 to Figure 5 , the embodiment of the present invention provides a flue gas control system in the production and casting process of a submerged arc furnace. The system includes a factory building, and a plurality of aluminum alloy windows 10 are arranged on both side walls of the factory building. The windows 10 include window frames 11. As well as a number of elongated blades 12 and first connecting rods 13 installed on the window frame 11 for adjusting opening or closing, a controller 20 is also installed in the fact

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap