Motor monitoring early warning method and system

A technology of motor monitoring and monitoring end, which is applied in the field of motor monitoring and early warning methods and systems, which can solve problems such as inability to early-stage early warning, economic loss, and failure to restore the fault site, and achieve the effect of improving reliability and comprehensiveness, and achieving comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

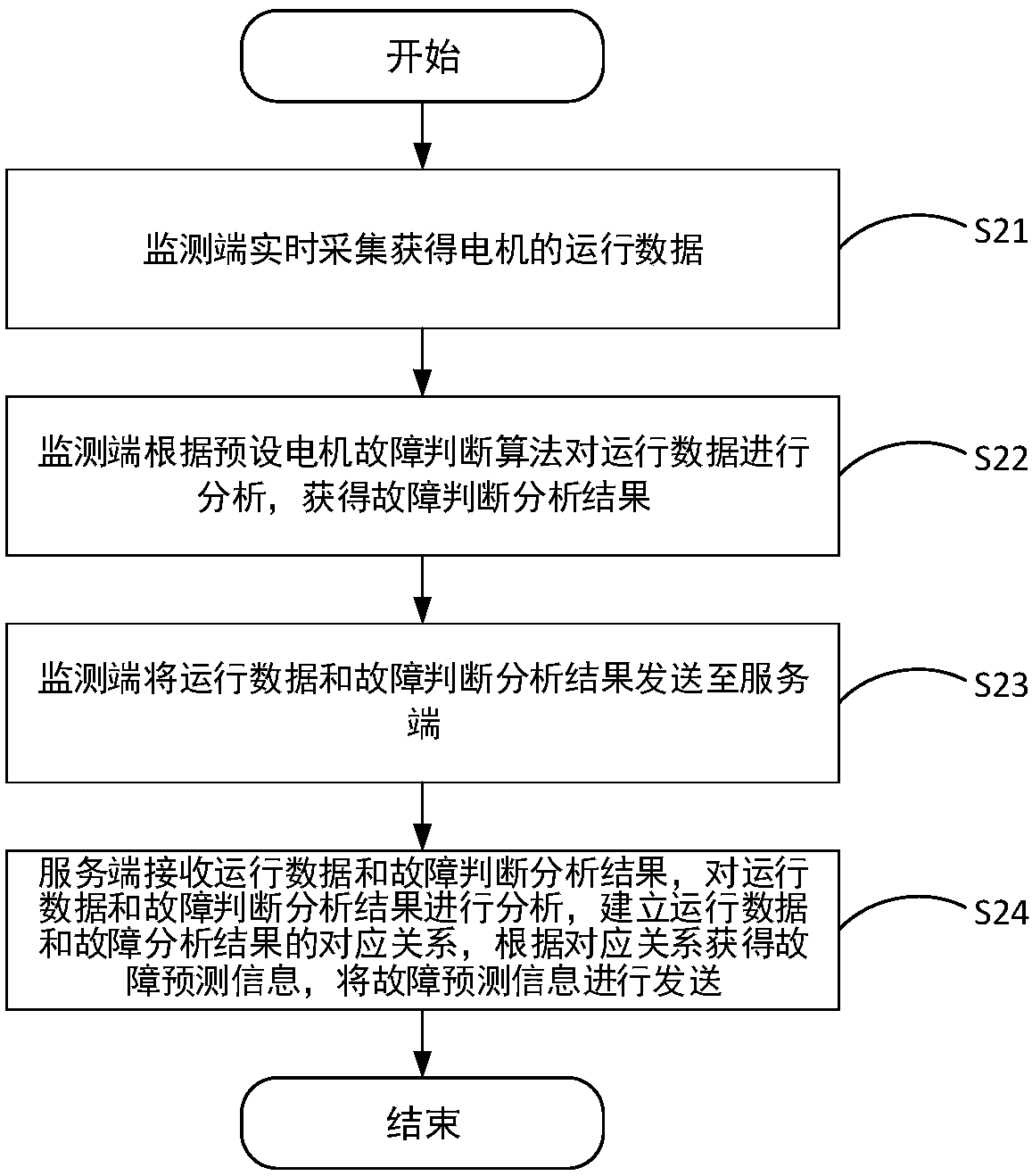

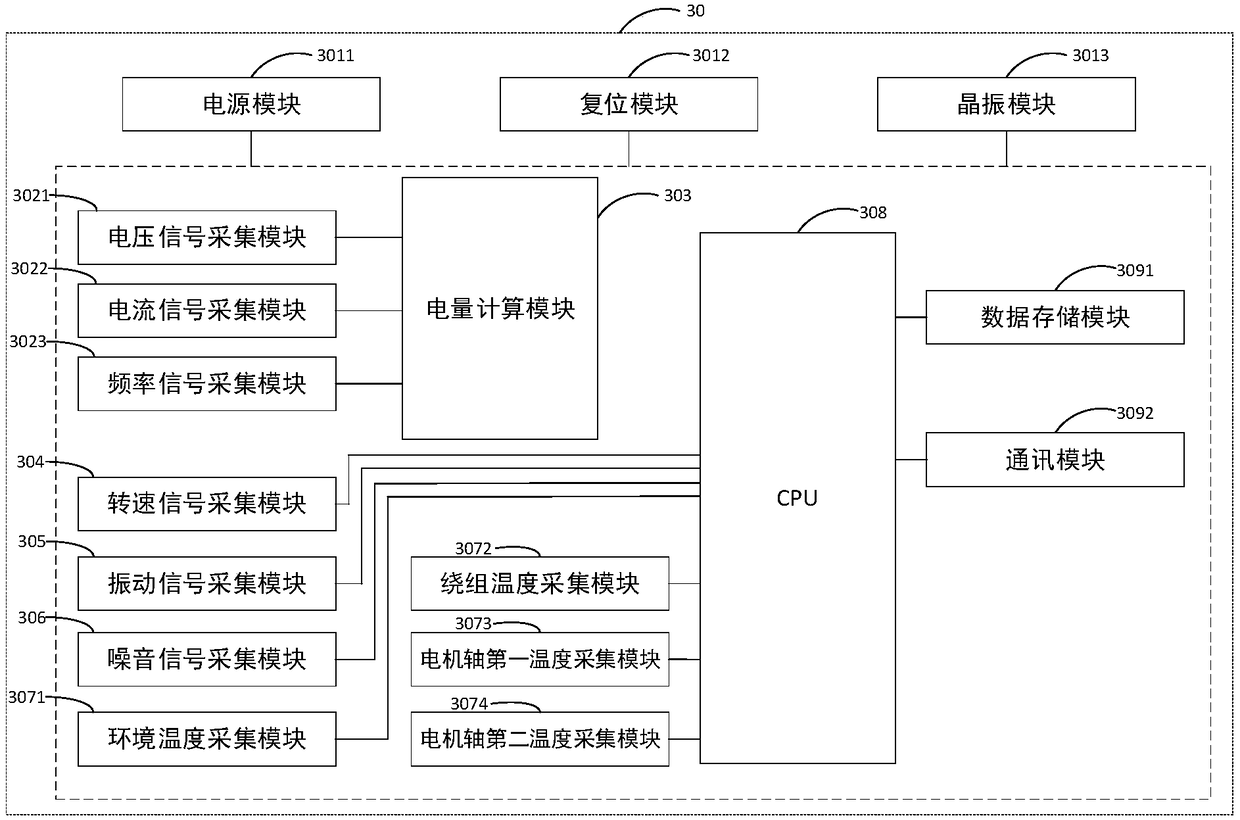

Method used

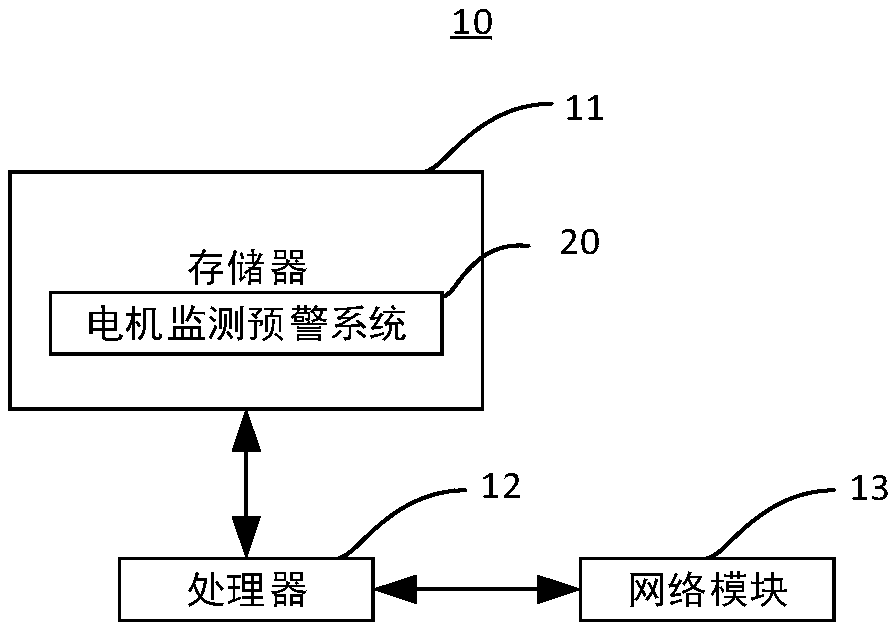

Image

Examples

Embodiment Construction

[0040] After investigation, it is found that most of the existing methods for monitoring the running state of the motor are not comprehensive. For example, the existing motor detection technology is generally an offline detection method. When the equipment is shut down, the maintenance personnel conduct routine inspection and maintenance on the motor based on their own experience. Although this detection method can also find some motor faults, it is often lagging behind and cannot give early warning at the initial stage of the fault. Recovering major economic losses; and before the power outage maintenance, it is necessary to coordinate relevant departments, select the appropriate downtime time, make maintenance preparations and preparation plans, which may cause interruptions to work and production; and this offline maintenance method, often Destroying the fault site, some faults only occur under specific conditions, and the fault site cannot be restored after shutdown, and the c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap