Laser ranging calibration device and calibration method thereof

A calibration device and laser ranging technology, applied in the field of measurement and calibration, can solve the problems of reduced applicability of the laser ranging system, and achieve the effects of low cost, satisfactory accuracy, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

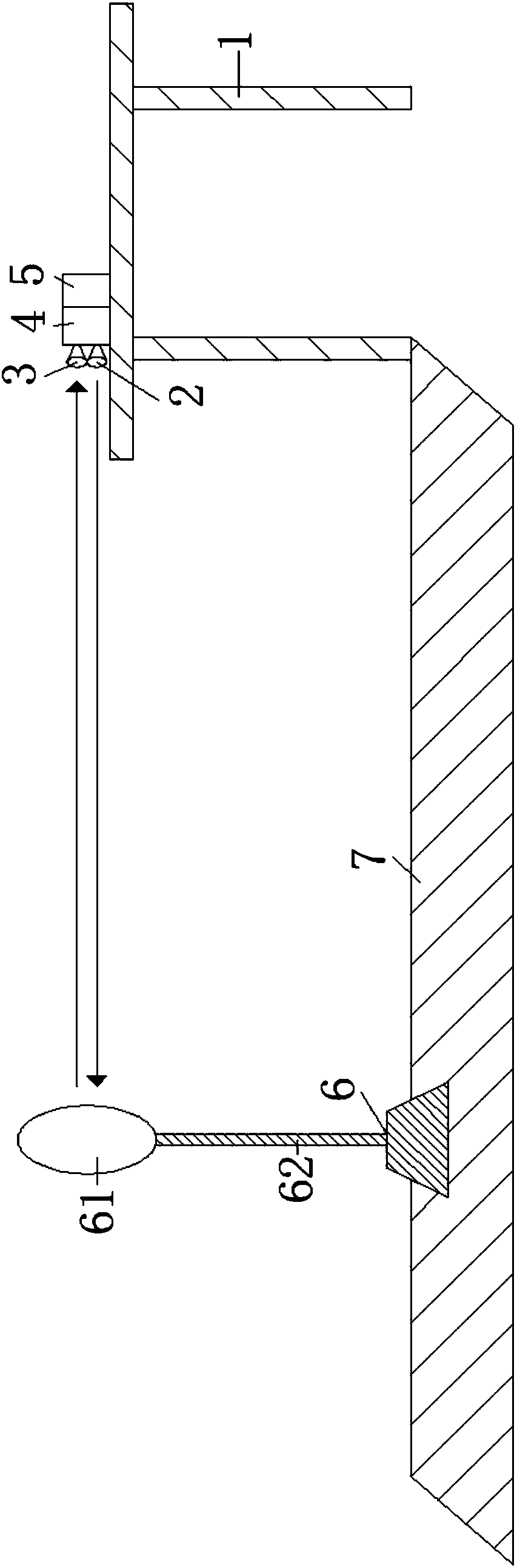

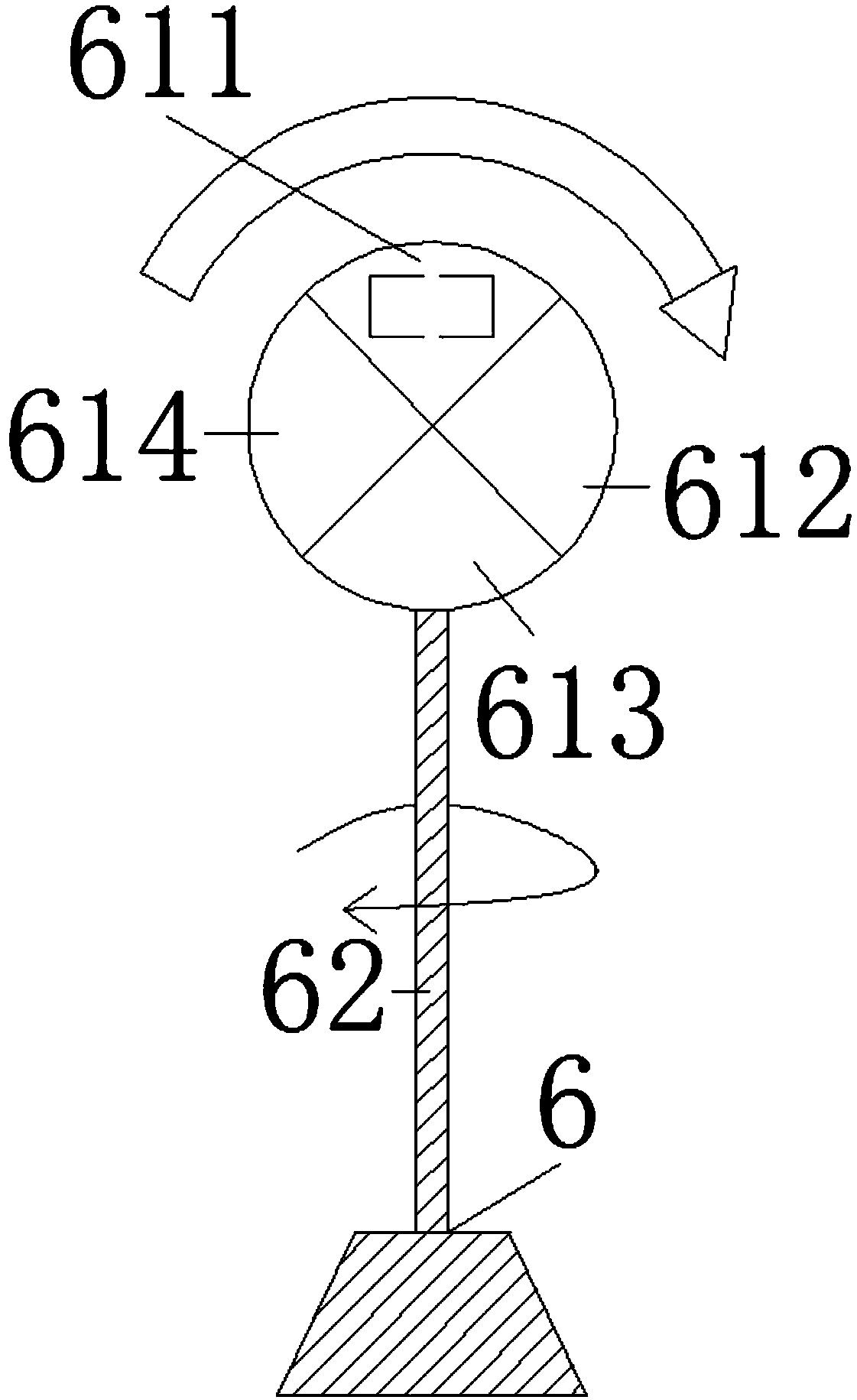

[0039] Such as Figure 1-4 As shown, the present embodiment provides a laser ranging calibration device including a test bench 1. First, a laser transmitter 2, a laser receiver 3, a data processor 4 and a reflector controller 5 are fixedly installed on the test bench 1, and then the One side of the test bench is provided with a track 7 and a reflector base 6 . A reflector 61 is attached to a central axis 62 of the reflector base 6 .

[0040] The input port of the laser transmitter is connected to the data processor, and is used to receive the electric excitation control signal transmitted by the data processor, and the output port of the laser transmitter is set against the reflector; the laser transmitter 2 for emitting laser signals to the reflection plate 61. Specifically, the laser transmitter includes a control circuit, an optical path and a laser.

[0041] The laser receiver is arranged in the area covered by the reflected laser of the reflector, the laser receiver is co

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap