Bagging machine for fruit trees

A bagging machine and bagging technology, applied in plant protective covers, botanical equipment and methods, gardening, etc., can solve problems such as economic loss, low work efficiency, and lower quality and price of kiwi fruit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further detailed explanation through specific implementation mode below:

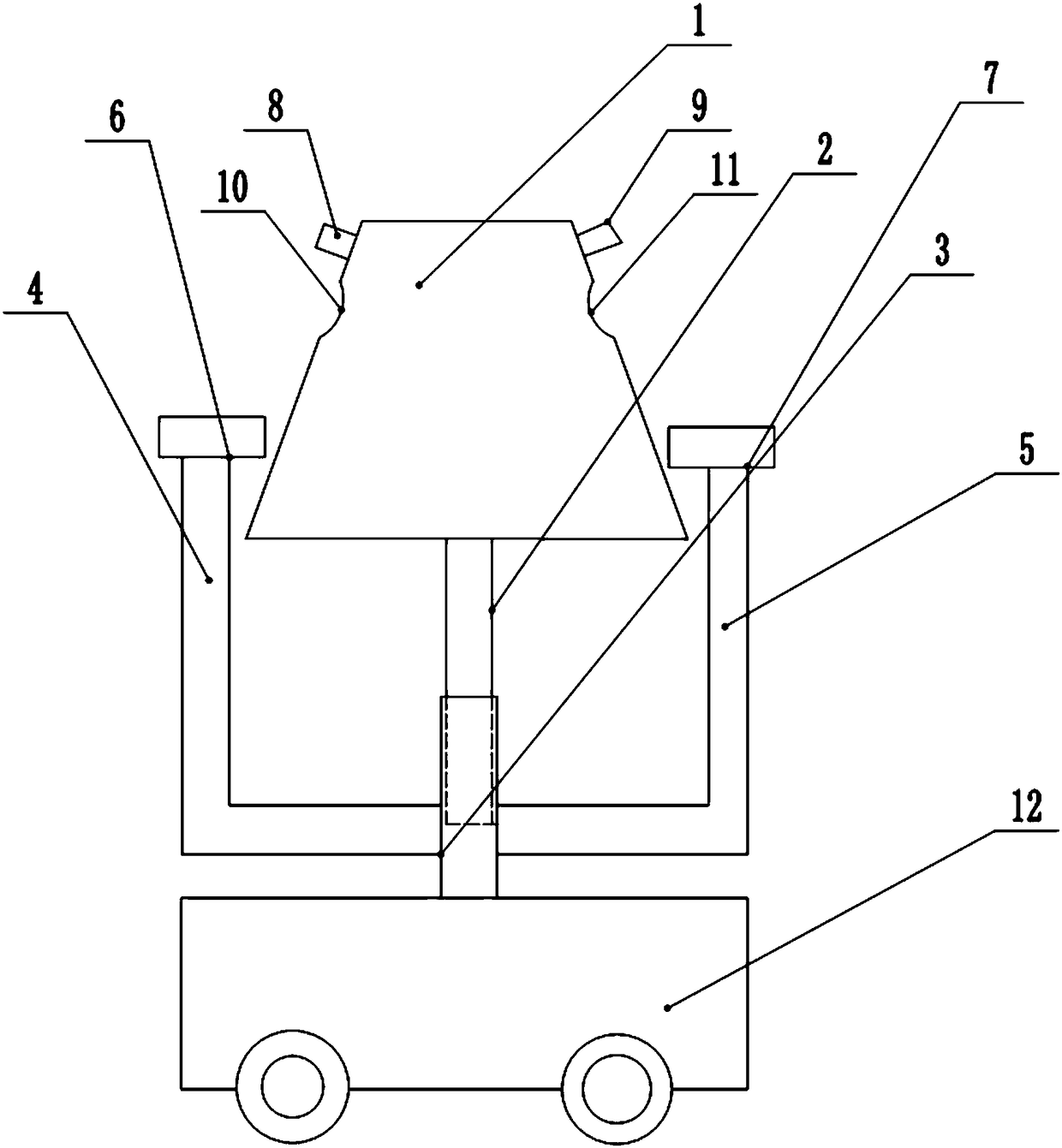

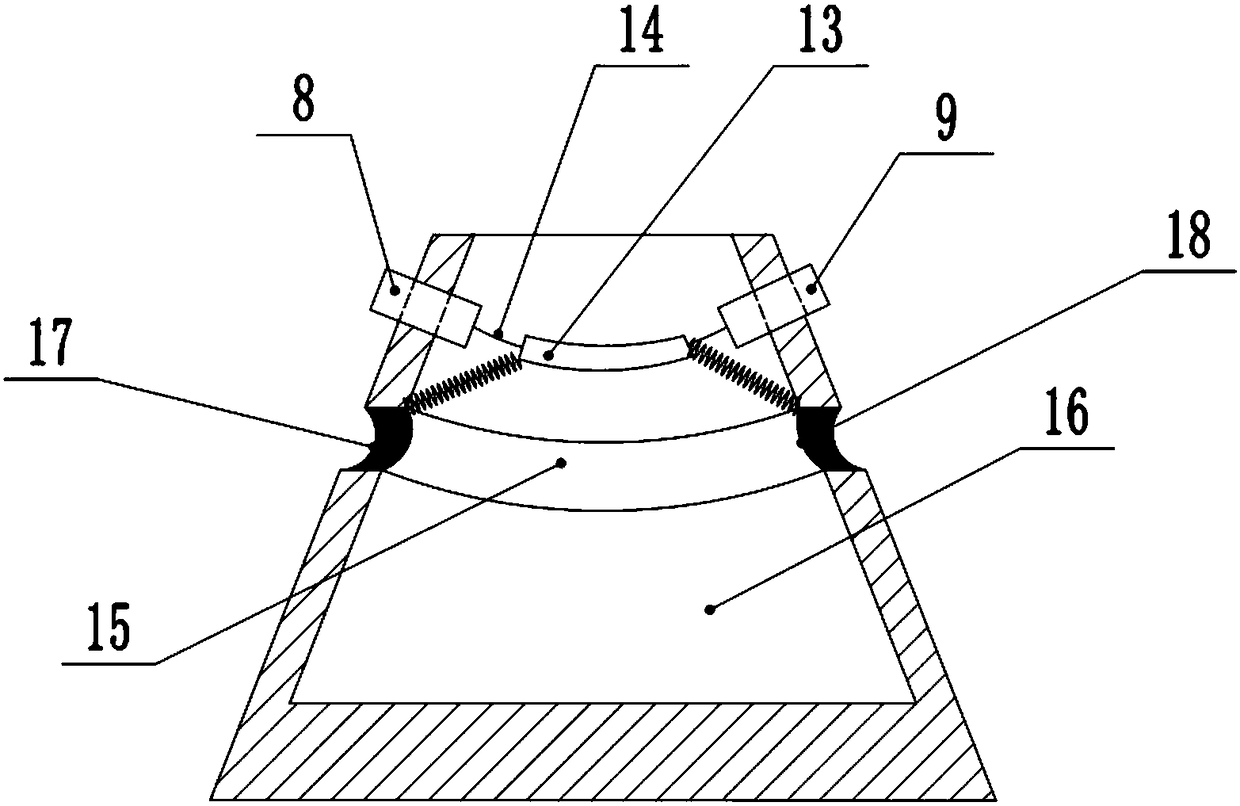

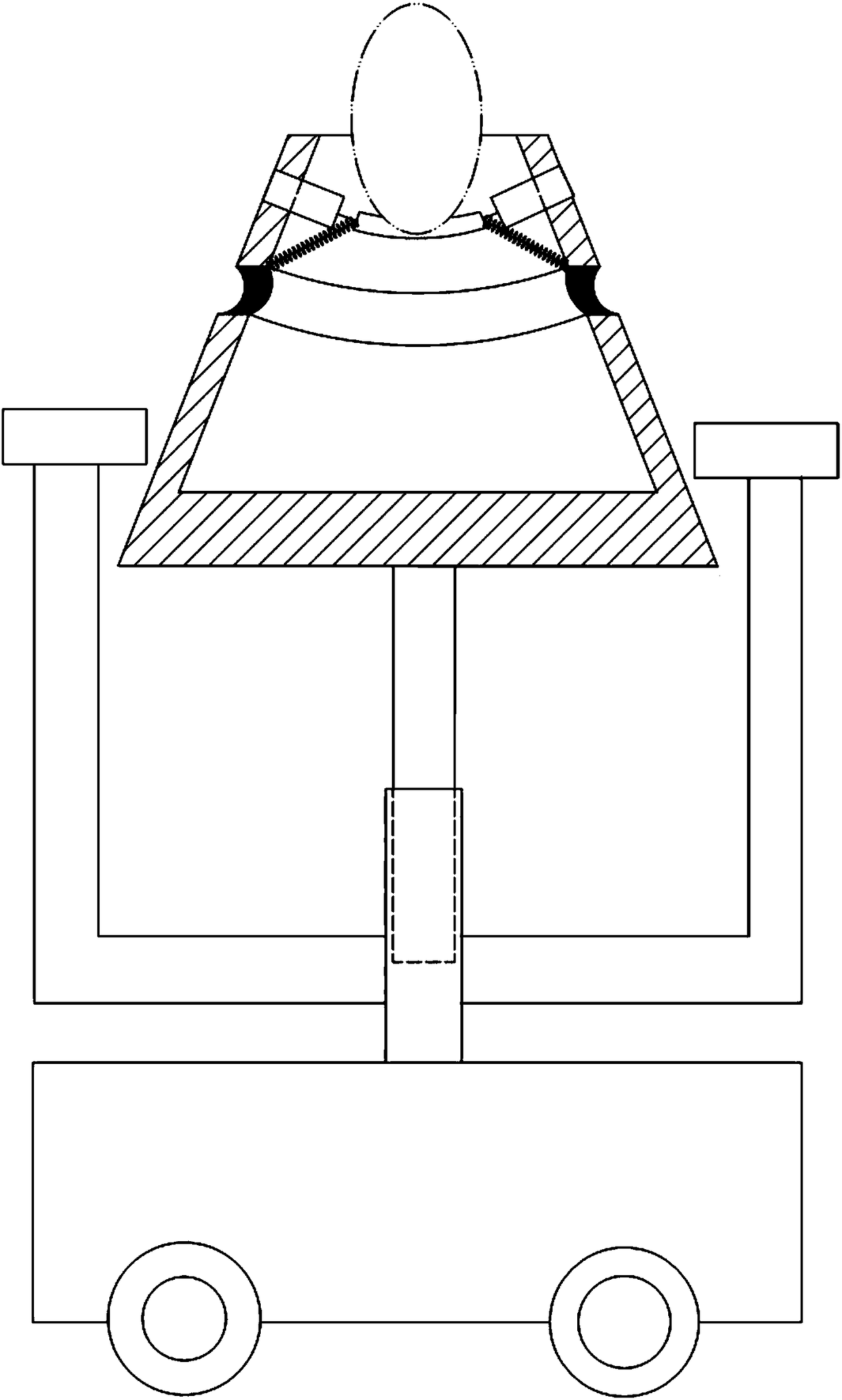

[0026] The reference signs in the accompanying drawings of the specification include: bagging tube 1, first-stage telescopic rod 2, fixed rod 3, first support rod 4, second support rod 5, first strip-shaped rubber block 6, second strip Shaped rubber block 7, first slider 8, second slider 9, first groove 10, second groove 11, mobile platform 12, cowhide pocket 13, rubber rubber band 14, rubber belt 15, fruit delivery channel 16 , the first rubber block 17, the second rubber block 18.

[0027] The embodiment is basically as attached figure 1 And attached figure 2 Shown: a fruit tree bagging machine, including a manually adjustable telescopic set rod, the telescopic set rod includes a fixed rod 3 and a primary telescopic rod 2, and the left side of the fixed rod 3 is fixedly connected with a first telescopic support rod 4 , the right side is fixedly connected with a telescopic second support rod 5,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap