Water injection tank and washing machine

A technology for washing machines and sinks, applied in the field of washing machines, which can solve the problems of poor removal of heavy metals, complex structure of water purification devices, and difficulty in universalization, etc., and achieve the effects of saving filter materials, saving expenses, and reducing the chance of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0048] Example one

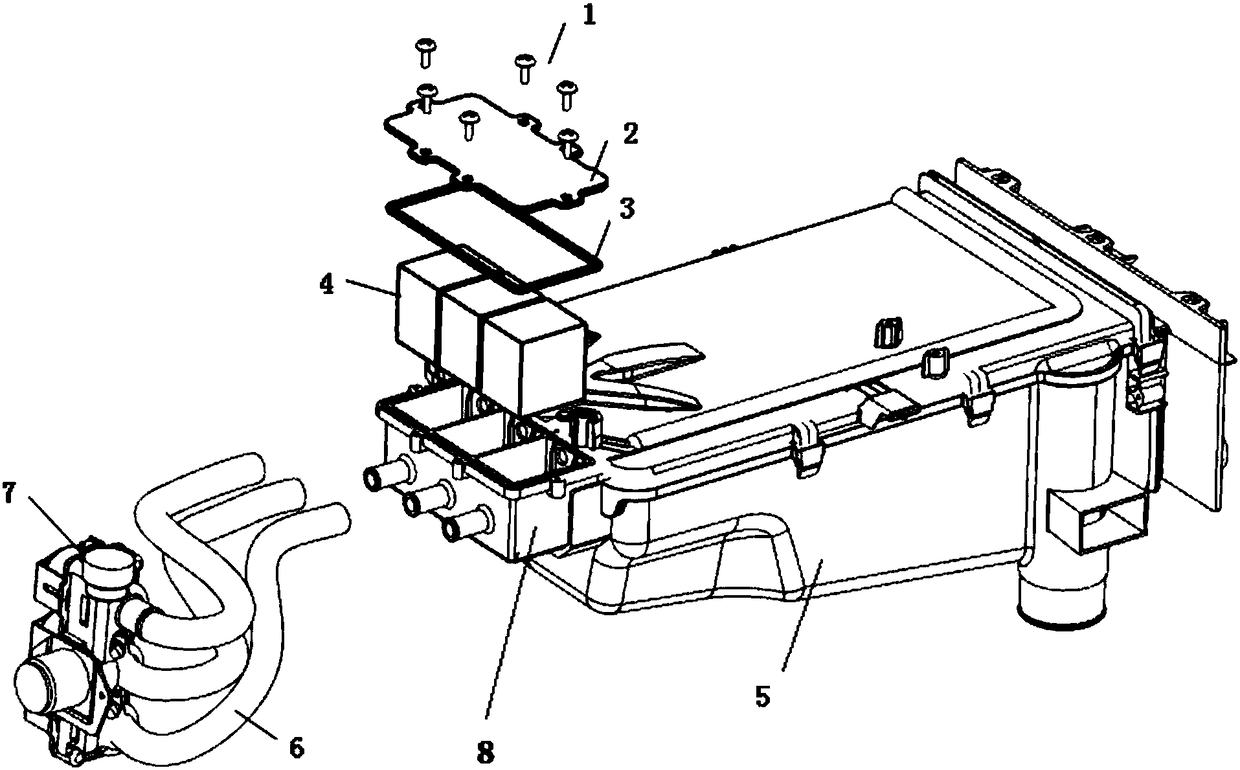

[0049] A water injection tank with filtering function, comprising a water injection tank body 5, a water purification chamber 8 is installed on the inlet side of the water injection tank body 5, and a filter element 5 composed of KDF and / or calcium sulfite is installed in the water purification chamber 8 , The water inlet pipeline of the water injection tank is directly connected to the water purification chamber 8.

[0050] The filter element 4 composed of KDF and / or calcium sulfite can be removed and replaced in the water purification chamber 8.

[0051] The KDF of the present invention is a high-purity copper and zinc alloy. There are two types of KDF available now: KDF55 and KDF85. Among them, KDF55 refers to an alloy of 50% copper and 50% zinc; KDF85, which is 85% An alloy of copper and 15% zinc.

[0052] The prior art water purification device has a complicated structure and the filter element cannot be replaced. The filter element 4 in the water purificat

Example Embodiment

[0073] Example two

[0074] The difference between this embodiment and the first embodiment is that the composition of the filter element 4 is optimized.

[0075] The filter element 4 used in this embodiment includes KDF55 and calcium sulfite, and the mass ratio of KDF55 to calcium sulfite is 15-23:1.

[0076] The use of the filter element with the above-mentioned material and mass ratio can further improve the purification effect of the water purification chamber, and the laundry is hygienic and healthy.

[0077] The washing machine can prevent heavy metals, residual chlorine and microorganisms from polluting clothes, is more hygienic and healthy, and meets the needs of users. In addition, it only needs to carry out simple transformations on the structure of the washing machine, saves R&D and production costs, and has a promising market prospect.

Example Embodiment

[0078] Example three

[0079] The difference between this embodiment and the first embodiment is that the composition of the filter element 4 and the partial structure of the water injection tank are optimized.

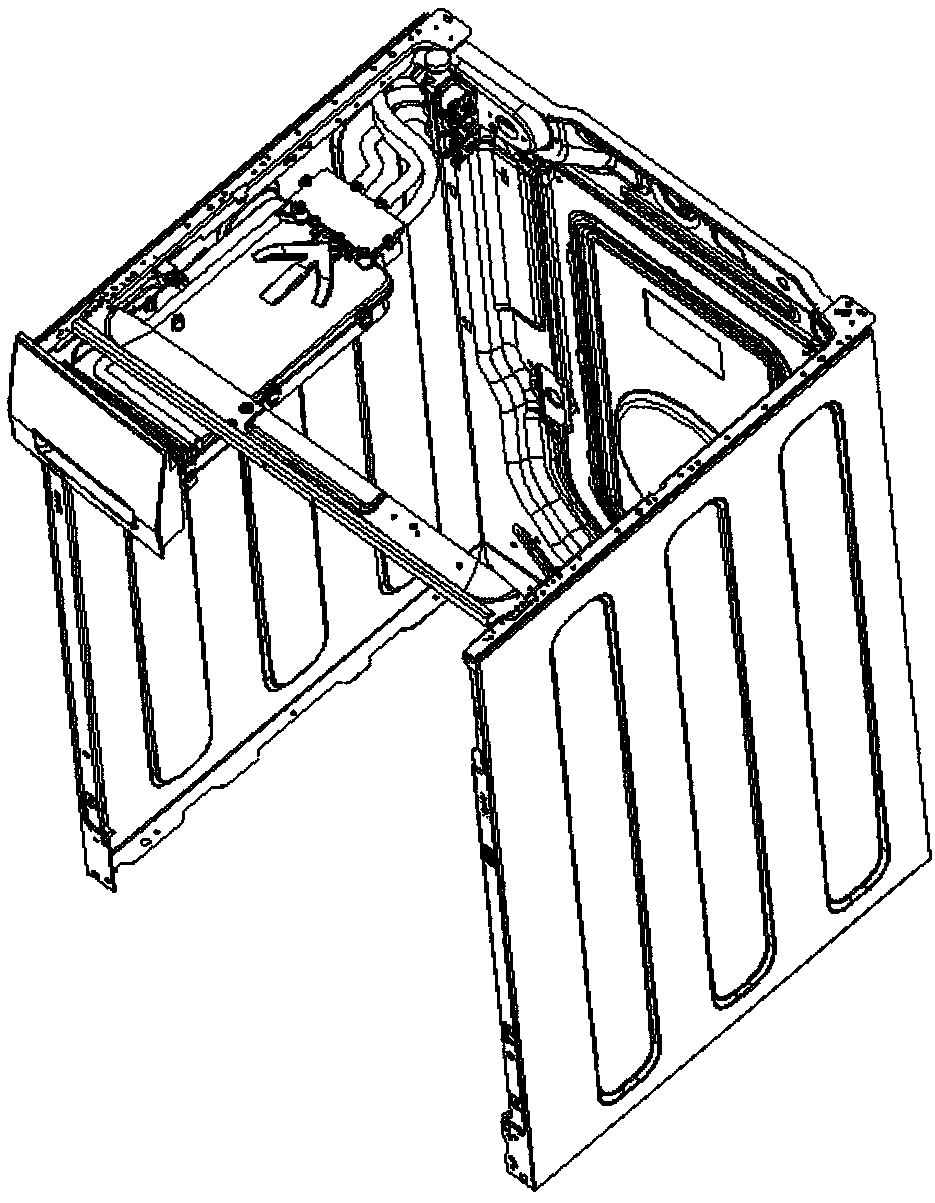

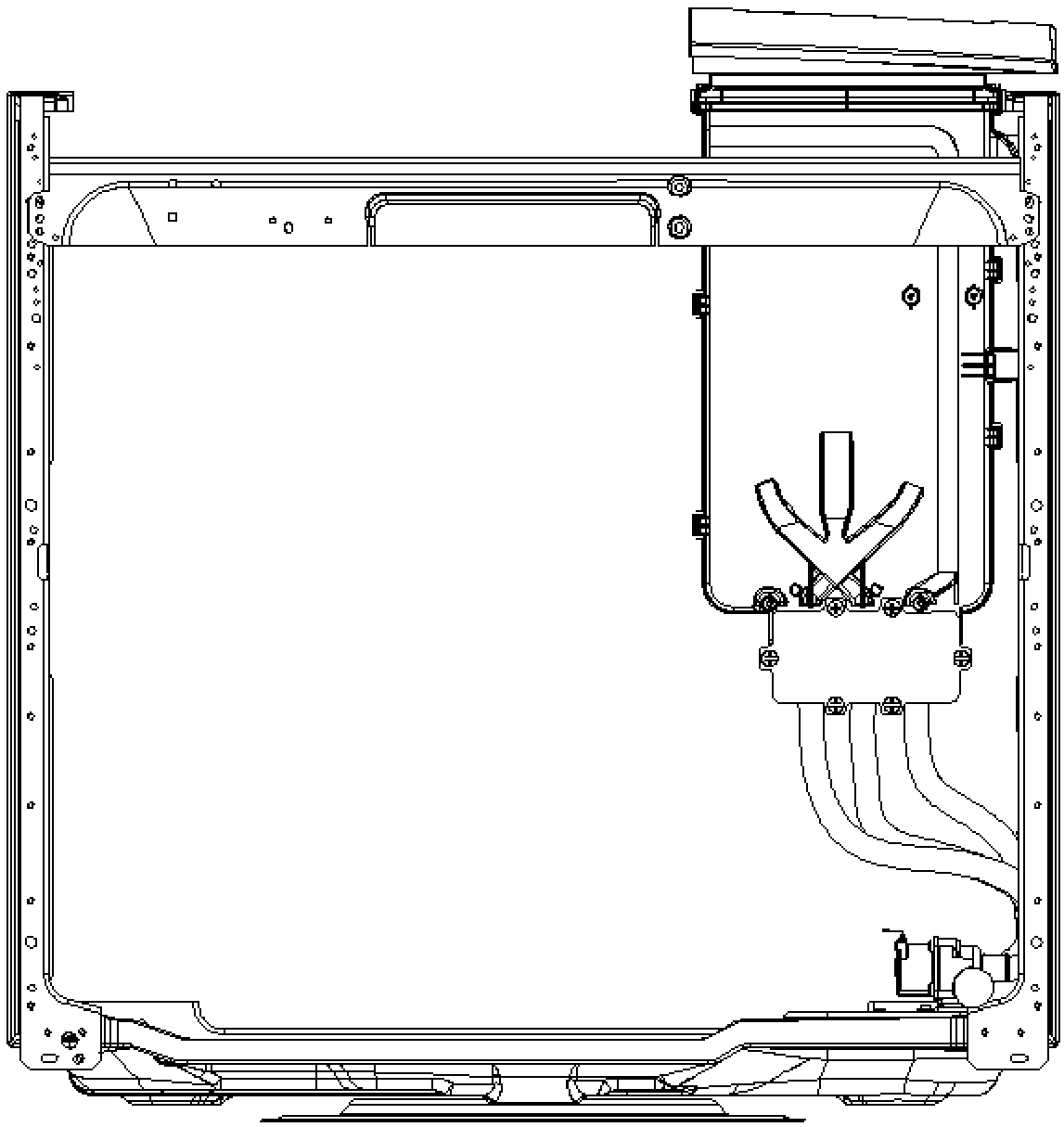

[0080] Such as figure 1 As shown, the water injection tank includes a water injection tank body 5 and a water purification chamber 8 integrally integrated with the water injection tank body 5. A filter element 4 composed of KDF and calcium sulfite is provided in the water purification chamber 8.

[0081] The KDF of the present invention is a high-purity copper / zinc alloy. The KDF includes KDF55 and KDF85, and can be selected from one or two of KDF55 or KDF85 when in use.

[0082] The KDF of the water purification chamber and the filter element 4 of calcium sulfite can be removed from the water purification chamber 8 for replacement.

[0083] The prior art water purification device has a complicated structure, and the filter element cannot be replaced. However, the filter element

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap