Electric construction lifting frame

A technology of electrical construction and hoisting frame, which is applied in the direction of transportation and packaging, load hanging components, etc. It can solve the problems of product drop damage, deformation and decoupling of the top plate of the electrical cabinet, and inability to adapt to the electrical cabinet, so as to prevent dumping and have good versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

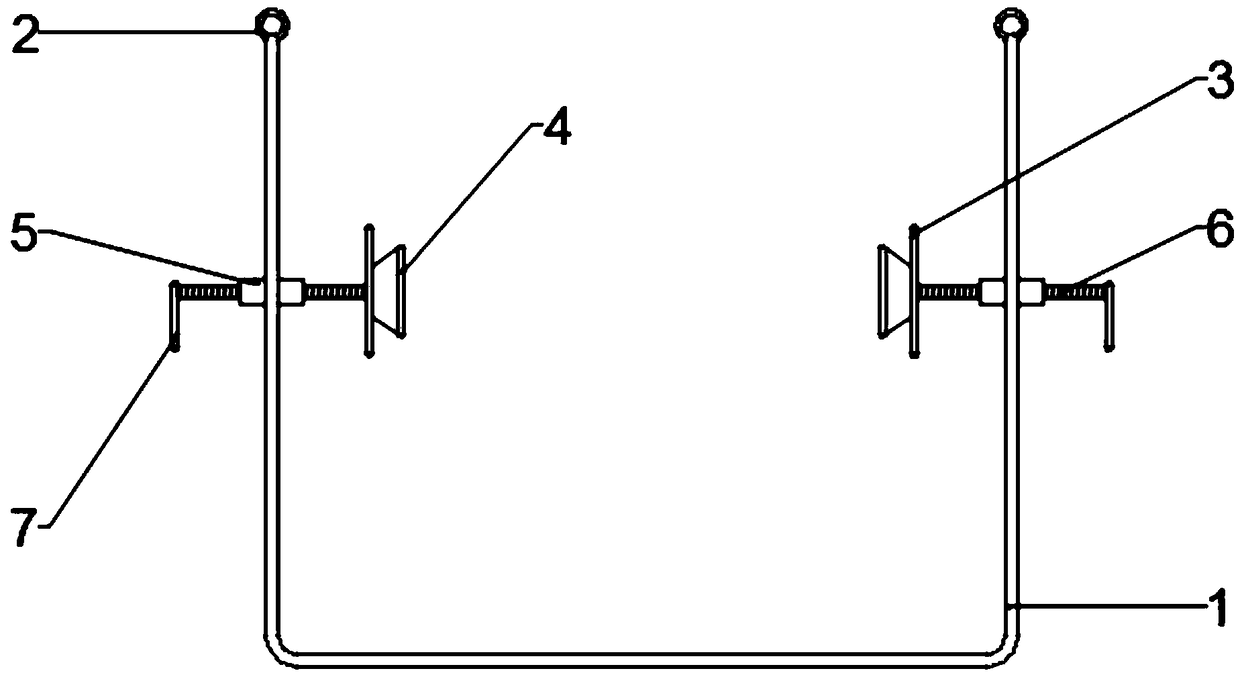

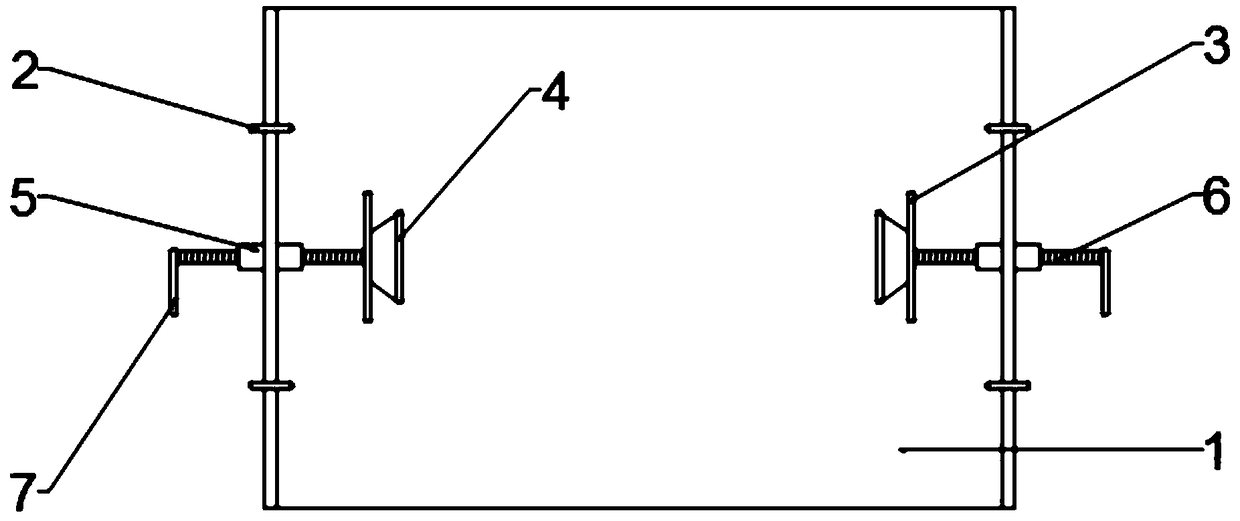

[0017] figure 1 with figure 2 Show the specific implementation of the electrical construction hoisting frame of the present invention:

[0018] Combine figure 1 with figure 2 , An electrical construction hoisting frame, which is characterized in that it comprises a hoisting frame sleeve 1 with a "concave" cross-section, a number of hoisting rings 2 are symmetrically arranged on the top of the hoisting frame sleeve 1, and both sides of the hoisting frame sleeve 1 A threaded pipe 5 is vertically arranged, and the two threaded pipes 5 are respectively connected with threaded rods 6 through threads. The ends of the two threaded rods 6 located in the hoisting frame sleeve 1 are vertically provided with a pressing plate 3 and a pressing plate 3 A suction cup 4 is provided on the side away from the threaded rod 6 where it is located, and a handle 7 is vertically provided at one end of the two threaded rods 6 located outside the hoisting frame sleeve 1. The handle 7 can be pulled to dri

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap