Anti-sliding-deformation roadbed reinforcing structure of high-speed railway in talus landslide area

A structure strengthening and anti-slip technology, applied in the field of geotechnical engineering, can solve problems such as huge project investment, and achieve the effect of good economy and simple structure construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] The present invention will be further described below in conjunction with the drawings and embodiments:

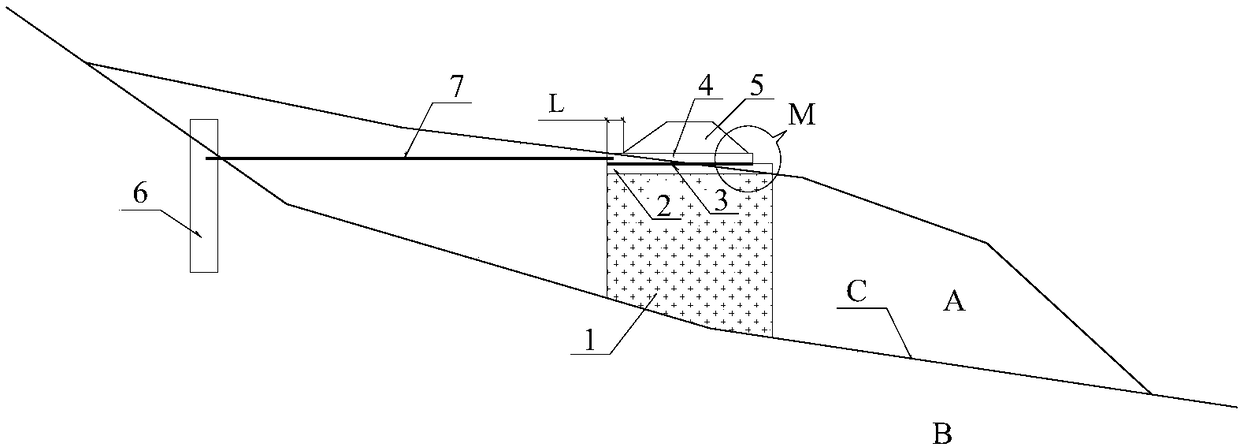

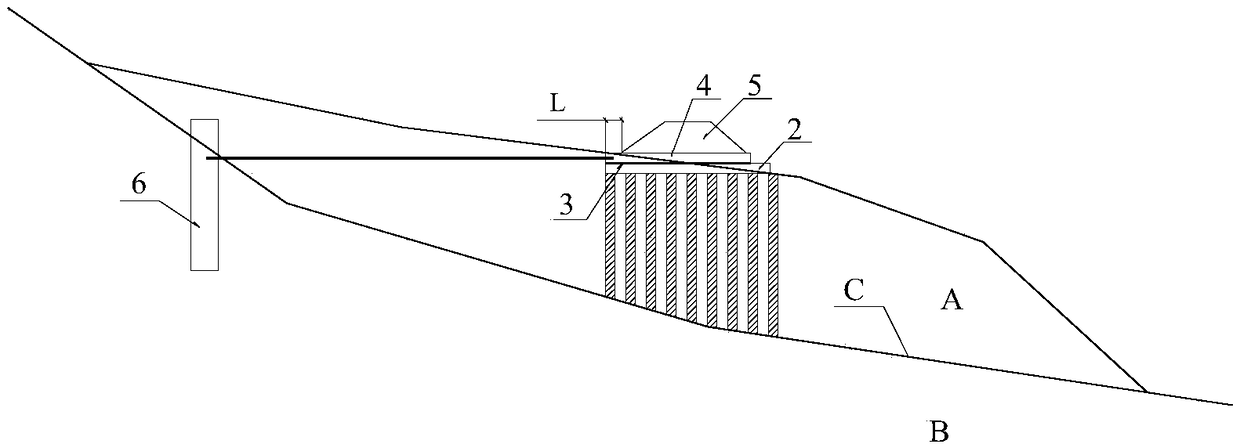

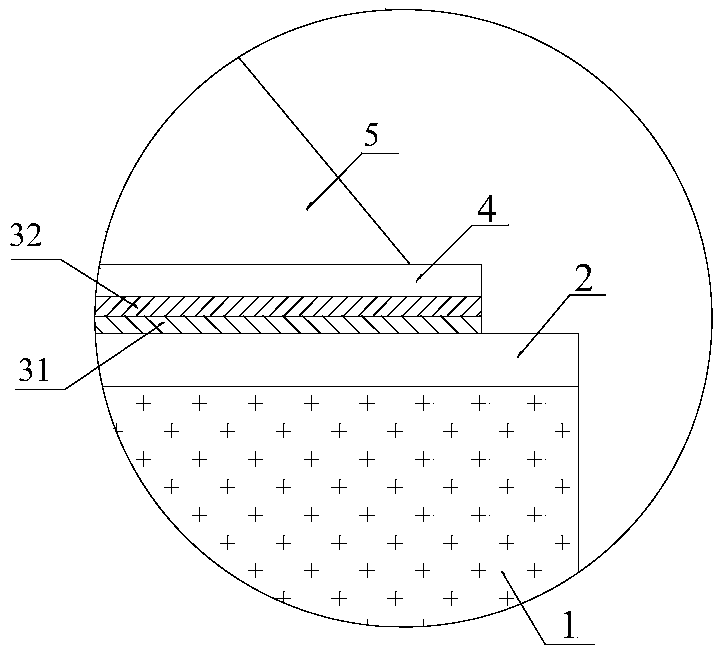

[0014] Reference figure 1 with figure 2 An anti-slip deformation subgrade reinforcement structure for a high-speed railway in a rock pile landslide area includes: a reinforcement 1 and a support base 2. The reinforcement 1 is arranged in the rock pile landslide body A below the subgrade structure 5, and the support base 2 is fixedly arranged in the The top of the solid 1; the sliding layer 3 and the subgrade foundation 4, the sliding layer 3 is set on the top surface of the supporting base 2, the subgrade foundation 4 is set on the top surface of the sliding layer 3, and the subgrade structure 5 is filled on the subgrade foundation 4; resistance pile 6 , Arranged in the rock pile landslide body A on the upslope side of the subgrade structure 5 at intervals along the extension direction of the line, the lower part of which passes through the sliding surface C and is anchor

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap