Steel pipe and corrugated steel plate combined hanging box cofferdam and construction method

A technology of corrugated steel plate and corrugated steel, which is applied in the direction of infrastructure engineering, construction, etc., can solve the problems of poor construction economy, long construction period, and slow construction speed, and achieve the effects of short construction period, saving construction period and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032] Example 1

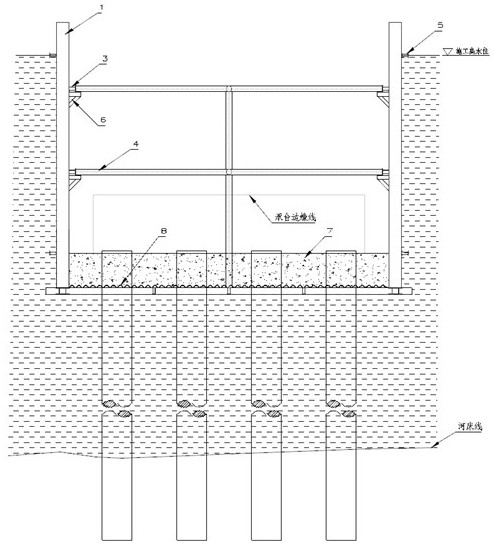

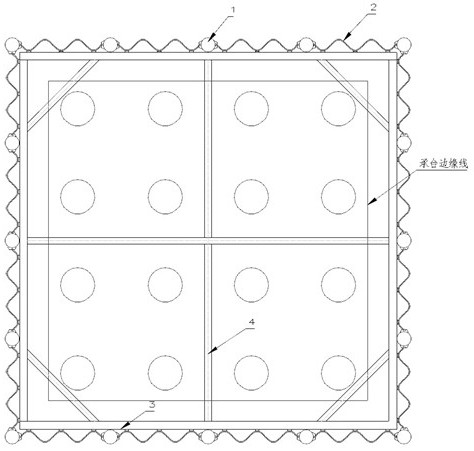

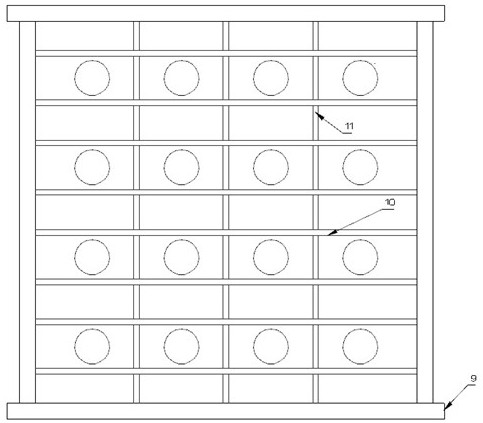

[0033] like Figure 1~Figure 3 , Figure 10 As shown, a steel pipe and corrugated steel plate combined hanging box cofferdam includes a bottom mold system and a side plate system connected to the upper part of the bottom mold system, wherein: the bottom mold system includes a plurality of main load-bearing beams 9, corrugated Steel base plate 8, the main load-bearing beams 9 are fixedly connected end to end to form a frame structure, and the corrugated steel base plate 8 is arranged above the frame structure; the side plate system is a box-shaped structure, including a A plurality of vertically arranged steel pipes 1 are distributed, and corrugated steel wall plates 2 are fixedly connected between adjacent steel pipes 1. The axis direction of the steel pipes 1 is perpendicular to the corrugated cross-section of the corrugated steel wall plates 2, so The inside of the box-type structure of the side plate system is provided with a support assembly for supportin

Example Embodiment

[0035] Example 2

[0036] Preferably, on the basis of Embodiment 1, in this embodiment, as Figure 4 As shown, the corrugated steel wall plate 2 and the steel pipe 1 are fixed by welding, and a stiffening plate 101 is provided at the welding place between the corrugated steel wall plate 2 and the steel pipe 1 .

[0037] In the actual use process, the corrugated steel wall plate 2 and the steel pipe 1 are fixed by welding, and the welding place between the corrugated steel wall plate 2 and the steel pipe 1 is provided with a stiffening plate 101 to ensure the wave shape. The connection strength of the steel wall plate 2 and the steel pipe 1.

Example Embodiment

[0038] Example 3

[0039] Preferably, on the basis of Embodiment 1, in this embodiment, the thickness of the corrugated steel wall plate 2 is ≥10 mm, the wavelength range of the corrugated steel wall plate 2 is 600-800 mm, and the wave height range is 220-300 mm.

[0040] In the actual use process, the side plate system of the present invention uses the corrugated steel wall plate as the bearing surface. By referring to the corrugated steel plate, the thickness of the corrugated steel wall plate 2 is ≥ 10mm, and the wavelength range of the corrugated steel wall plate 2 is 600-800mm. , the wave height range is 220 ~ 300mm, which reduces the number of connections with the steel pipe, making it have a faster construction speed. Under the condition of satisfying the lateral stiffness, the corrugated steel plate can give full play to the high strength, strong durability, short construction period, Economical features.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Wave height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap